Synthetic method of high yield red fluorescent carbon quantum dot material

A carbon quantum dot and red fluorescence technology, which is applied in the field of high-yield red fluorescent carbon quantum dot material synthesis, can solve the problems of low yield of red light and wavelength dependence of excitation light, etc. The effect of less amount, less by-products and intermediate products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of synthetic method of high yield red fluorescent carbon quantum dot material is characterized in that comprising the following steps:

[0031] a) Weigh 1g of citric acid and 2g of urea respectively, add them into 10mL of N,N-dimethylformamide, and stir until completely dissolved to obtain a precursor solution;

[0032] b) Transfer the precursor solution obtained in step a) to a 25mL polytetrafluoroethylene-lined hydrothermal reactor to keep warm at a temperature of 180°C for 6 hours, and then naturally cool to room temperature to obtain a suspension;

[0033] c) Add 1.25mol / L LiOH aqueous solution to the suspension obtained in step b) according to the volume ratio of the suspension and the alkali solution at 1:2, stir for two minutes, centrifuge at 13000rpm, take the precipitate and add deionized water to wash After centrifugation at 13,000 rpm, the precipitate was collected, and then vacuum-dried at 60° C. to obtain red fluorescent carbon quantum dots.

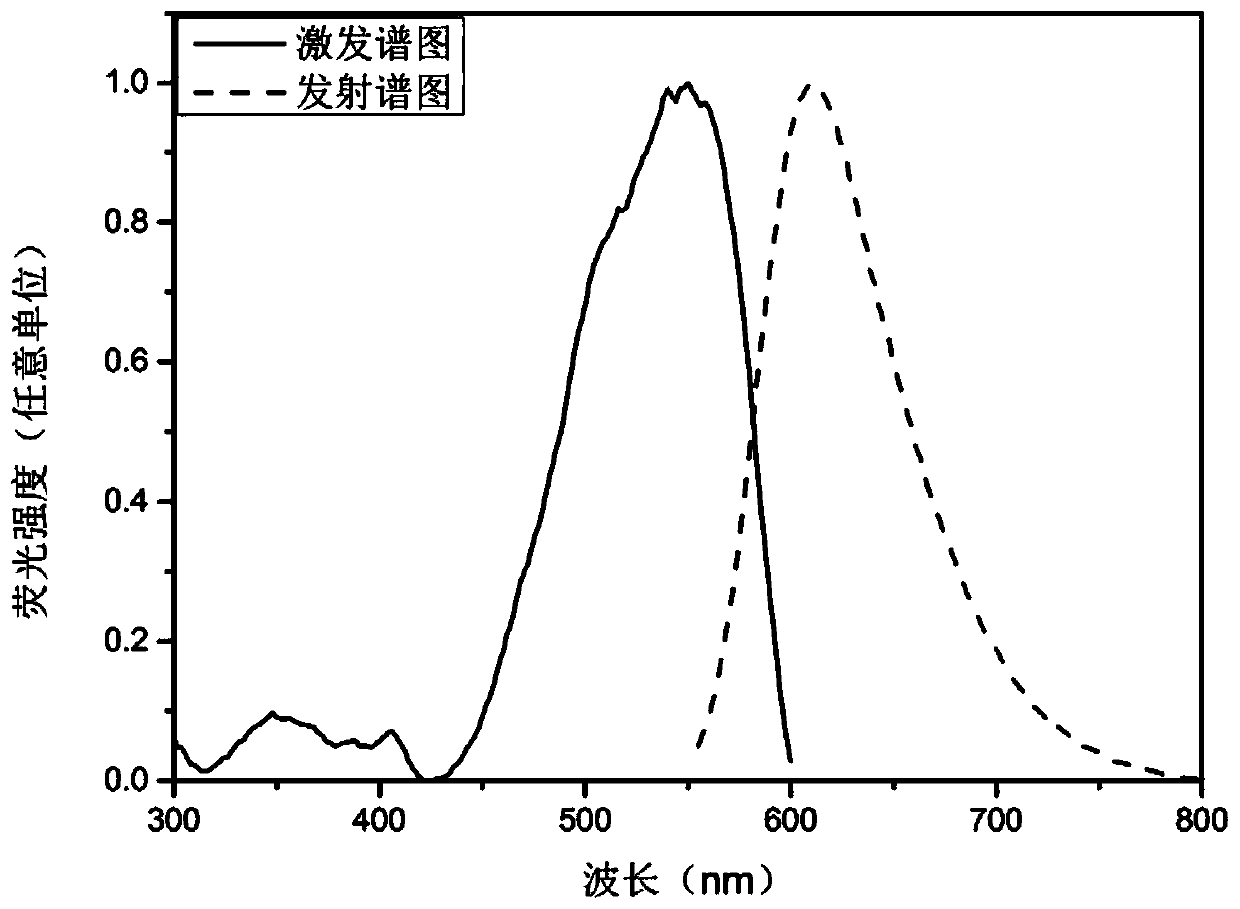

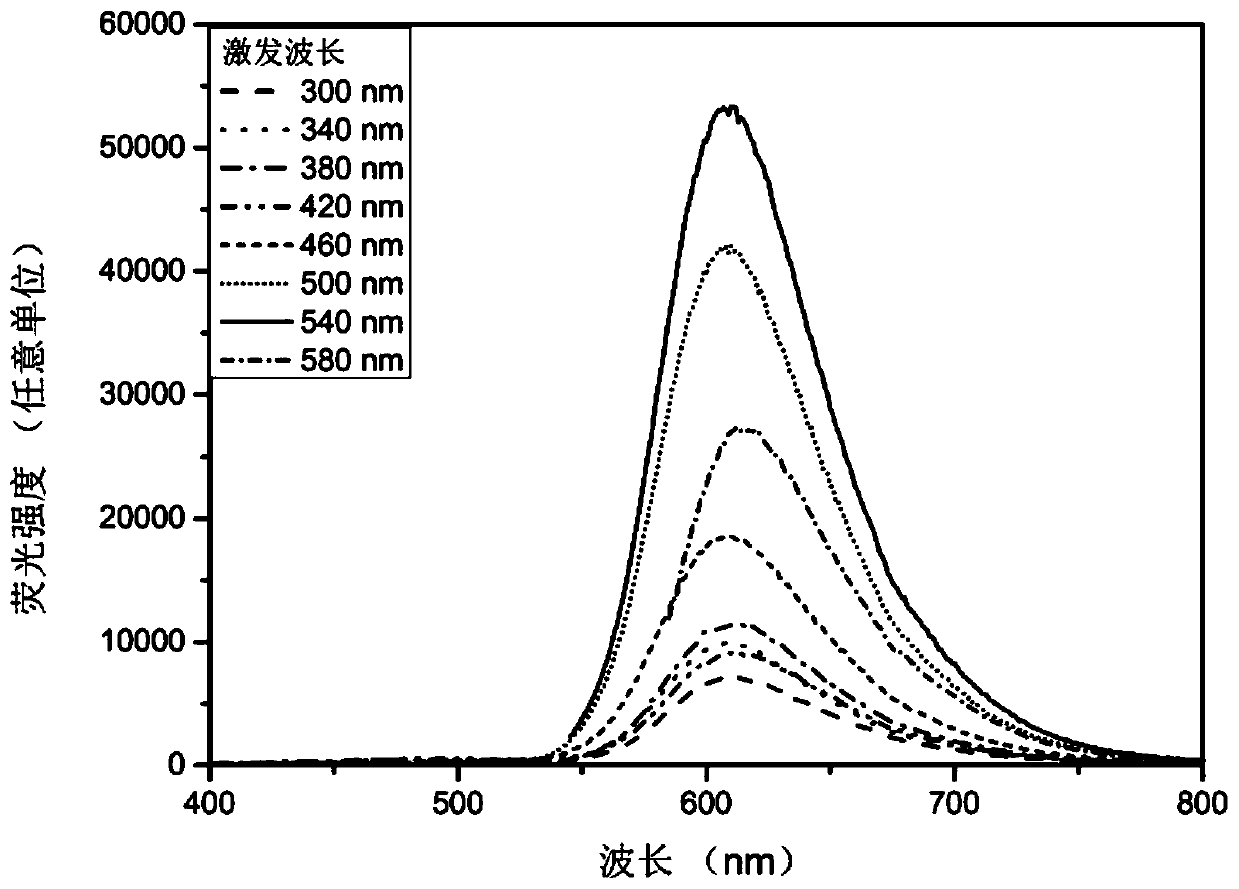

[0034...

Embodiment 2

[0036] A kind of synthetic method of high yield red fluorescent carbon quantum dot material is characterized in that comprising the following steps:

[0037] a) Weigh 1g of citric acid and 2g of urea respectively, add them into 10mL of N,N-dimethylformamide, and stir until completely dissolved to obtain a precursor solution;

[0038] b) Transfer the precursor solution obtained in step a) to a 25mL polytetrafluoroethylene-lined hydrothermal reactor to keep warm at a temperature of 180°C for 6 hours, and then naturally cool to room temperature to obtain a suspension;

[0039] c) Add 1.25mol / L KOH aqueous solution to the suspension obtained in step b) according to the volume ratio of the suspension and the alkali solution at 1:2, stir for two minutes, centrifuge at 13000rpm, and take the precipitate and add deionized water to wash After centrifugation at 13,000 rpm, the precipitate was collected, and then vacuum-dried at 60° C. to obtain red fluorescent carbon quantum dots.

[0...

Embodiment 3

[0042] A kind of synthetic method of high yield red fluorescent carbon quantum dot material is characterized in that comprising the following steps:

[0043] a) Weigh 1g of citric acid and 2g of urea respectively, add them into 10mL of N,N-dimethylformamide, and stir until completely dissolved to obtain a precursor solution;

[0044] b) Transfer the precursor solution obtained in step a) to a 25mL polytetrafluoroethylene-lined hydrothermal reactor to keep warm at a temperature of 180°C for 6 hours, and then naturally cool to room temperature to obtain a suspension;

[0045] c), add 0.75mol / L NaOH aqueous solution to the suspension obtained in step b) according to the volume ratio of the suspension and the alkali solution at 1:2, stir for two minutes, centrifuge at 13000rpm, take the precipitate and add deionized water to wash After centrifugation at 13,000 rpm, the precipitate was collected, and then vacuum-dried at 60° C. to obtain red fluorescent carbon quantum dots.

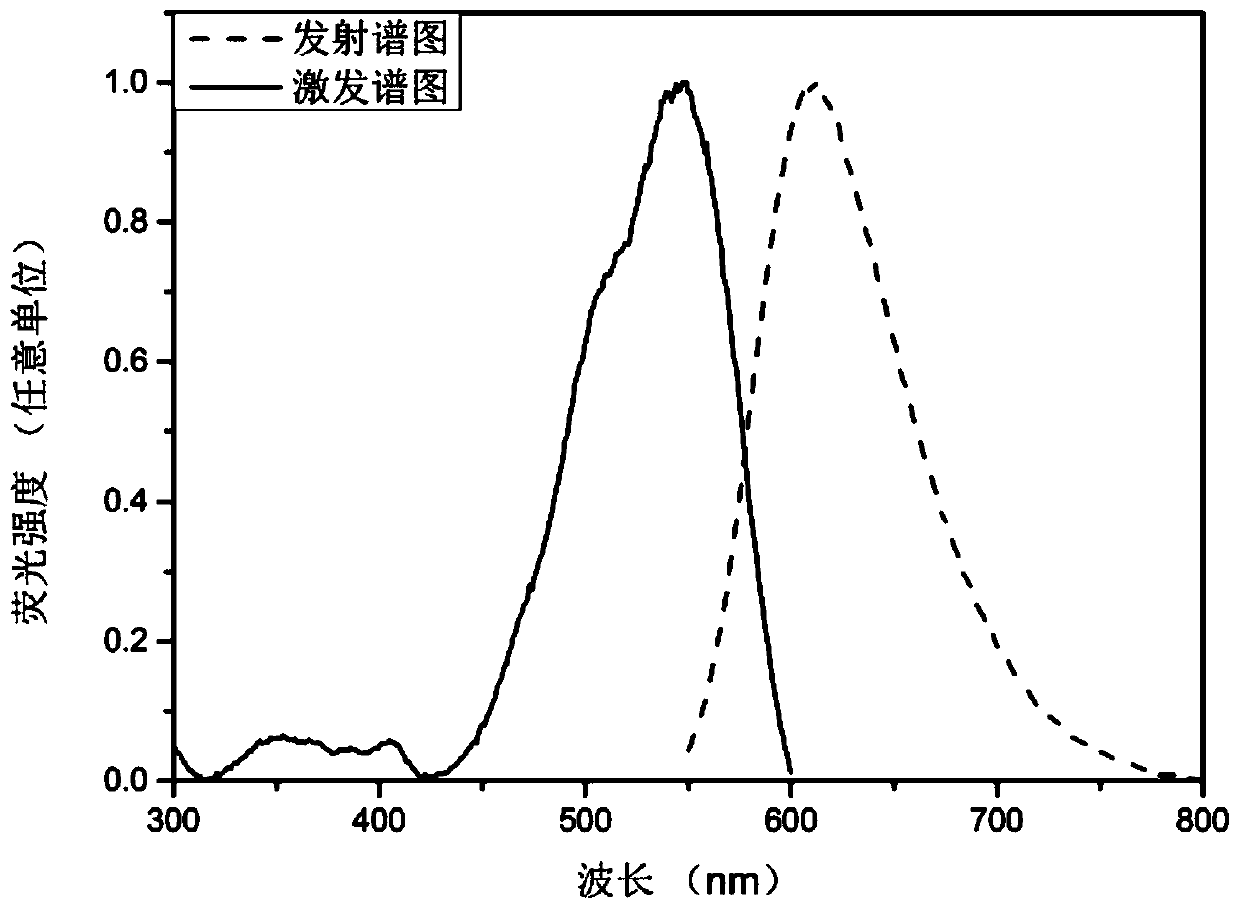

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com