Miniature wide-spectrum and high-sensitivity graphene fiber photoelectric detection chip

A photoelectric detection and graphene technology, applied in the field of optical fiber communication, can solve the problems of slow response speed of photoelectric detection chips, low detection efficiency, complicated manufacturing process, etc., so as to improve photoelectric detection efficiency, stabilize photoelectric detection sensitivity and compact chip structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

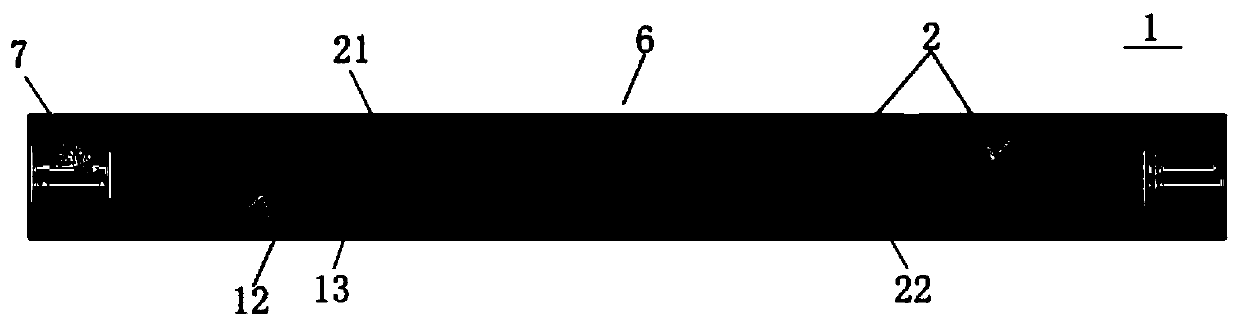

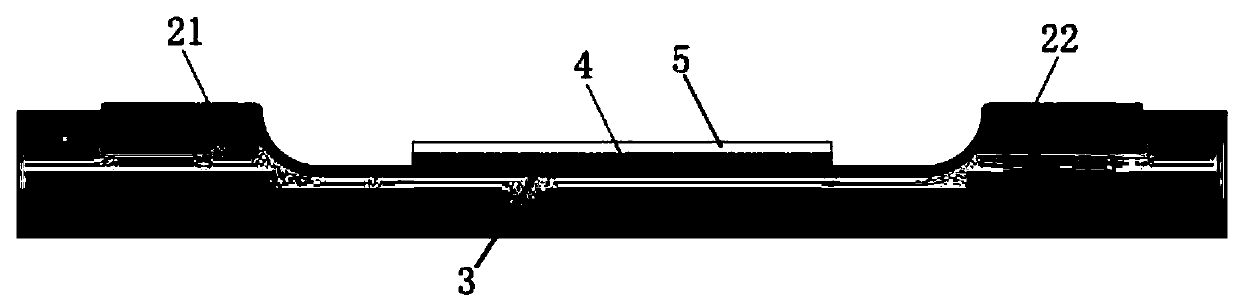

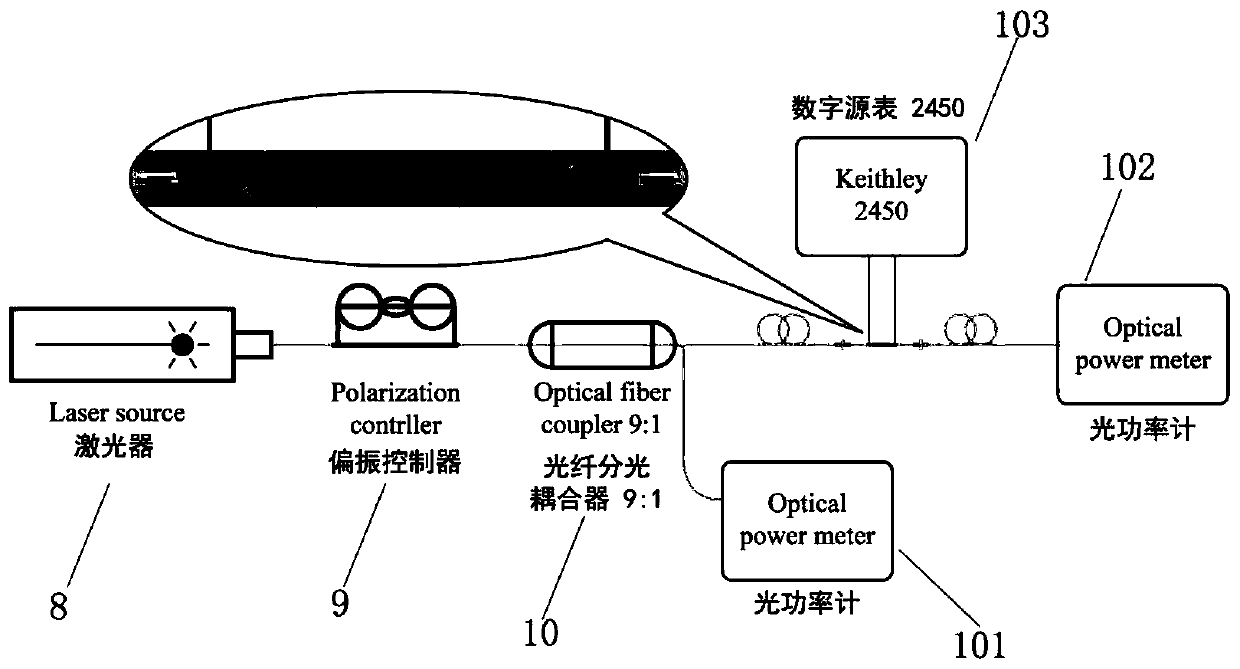

[0042] Such as Figure 1~2 As shown, the present embodiment includes a side-polished optical fiber 1, a microstrip electrode 2, a graphene film 3, a PB film 4, and a PMMA film 5, and the side-polished optical fiber 1 includes a cladding 12, a core 13, and a cladding 12 and the fiber core 13 are partially polished to form a polishing zone 6; the microstrip electrode 2 covers both sides of the fiber core 13 in the polishing zone 6 and extends to the non-polishing zone 7; the upper surface of the microstrip electrode 2 The surface is covered with PMMA film 5, PB film 4, and graphene film 3 sequentially from top to bottom, and the three film layers form a PMMA-PB-graphene composite film.

[0043] The microstrip electrode 2 includes a first metal electrode 21 and a second metal electrode 22, the first metal electrode 21 and the second metal electrode 22 are symmetrically distributed on both sides of the fiber core 13, covering the polishing area 6 and the non-polishing area 7 on. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com