Iron-doped TiO2-SiO2 composite aerogel, and preparation method and application thereof

A composite aerogel, iron-doped technology, applied in chemical instruments and methods, water/sludge/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as harsh conditions, etc. To achieve the effect of mild reaction conditions, avoidance of loss, and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

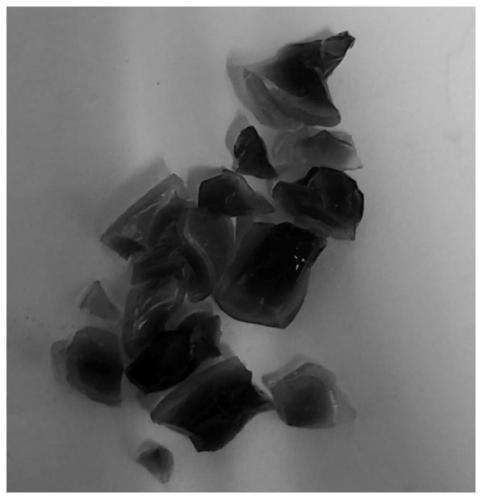

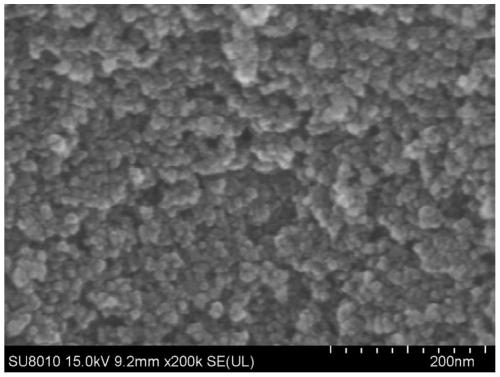

Image

Examples

Embodiment 1

[0038] (1) Prepare a solution with 0.02mL PEG (polyethylene glycol), 18.6mL absolute ethanol, 0.01g ferrocene and 0.01mL deionized water, and vigorously stir at 40°C with a temperature-controlled magnetic stirrer for 20 minutes;

[0039] (2) Add 1.42mL65.0~68.0(w / %) concentrated nitric acid, 8.9mL TEOS (tetraethyl orthosilicate), 3.5mL TIP (isopropyl titanate), 11.4mL HAc (glacial acetic acid), sealed and stirred at room temperature for 60min to form a mixed sol;

[0040] (3) Pour the mixed solution into a polypropylene tube and seal it, and age it at room temperature for 2 days to make it gel, then add TEOS / EtOH with a volume ratio of 1:1, and age the gel for 12 hours, and the aged Wash the gel with deionized water, put it into 0.5mol / L urea aqueous solution, and react it in a hydrothermal reactor at 120°C for 10 hours to make the surface of the gel hydrophilic;

[0041] (4) After the surface modification is completed, wash with n-hexane once every 12 hours for a total of tw...

Embodiment 2

[0044] (1) Prepare a solution with 0.02mL of PEG (polyethylene glycol), 18.6mL of absolute ethanol, 0.01g of ferrocene and 0.01mL of deionized water, and stir vigorously at 40°C for 20min with a temperature-controlled magnetic stirrer.

[0045] (2) Add 1.42mL65.0~68.0(w / %) concentrated nitric acid, 8.9mL TEOS (tetraethyl orthosilicate), 3.5mL TIP (isopropyl titanate), 11.4mL HAc (glacial acetic acid), sealed and stirred at room temperature for 60min to form a mixed sol.

[0046] (3) Pour the mixed solution into a polypropylene tube and seal it, and age it at room temperature for 2 days to make it gel. The generated gel was washed with deionized water, then put into 0.5 mol / L urea aqueous solution, and reacted in a hydrothermal reactor at 120°C for 10 hours to make the surface of the gel hydrophilic.

[0047] (4) After the surface modification is completed, wash with n-hexane once every 12 hours for a total of two times to replace the moisture in the gel, and then vacuum-dry a...

Embodiment 3

[0050] (1) Prepare a solution with 0.02mL PEG (polyethylene glycol), 18.6mL absolute ethanol, 0.02g ferrocene and 0.01mL deionized water, and stir vigorously at 40°C for 20min with a temperature-controlled magnetic stirrer.

[0051] (2) Add 1.42mL65.0~68.0(w / %) concentrated nitric acid, 8.9mL TEOS (tetraethyl orthosilicate), 3.5mL TIP (isopropyl titanate), 11.4mL HAc (glacial acetic acid), sealed and stirred at room temperature for 60min to form a mixed sol.

[0052] (3) Pour the mixed solution into a polypropylene tube and seal it, and age it at room temperature for 2 days to make it gel. The generated gel was washed with deionized water, then put into 0.5 mol / L urea aqueous solution, and reacted in a hydrothermal reactor at 120°C for 10 hours to make the surface of the gel hydrophilic.

[0053] (4) After the surface modification is completed, wash with n-hexane once every 12 hours for a total of two times to replace the moisture in the gel, and then vacuum-dry at 60°C for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com