Single-sided internal oxidation silver tin oxide indium oxide electric contact material and preparation method thereof

A technology of electrical contact materials, silver tin oxide, applied in the direction of contacts, circuits, electric switches, etc., can solve the problems of uneven material structure, complex process, product failure, etc., and achieve the effect of convenient and reliable welding process and uniform distribution of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

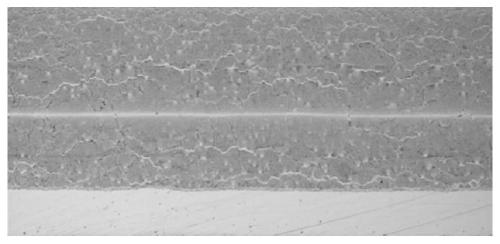

Image

Examples

Embodiment 1

[0049] To prepare Ag(92)SnO 2 -In 2 o 3 / AgSn20 and Ag(92)SnO 2 -In 2 o 3 / AgZn20 electrical contact material as an example

[0050] In the first step, Ag ingots, Sn ingots, In ingots, and additive Ni are melted and ingot-cast. Wherein the Ag content is 93.5wt%, the Sn content is 4.7wt%, the In content is 2.5wt%, and the Ni content is 0.3wt%.

[0051] In the second step, the alloy ingot obtained in the first step is extruded into an AgSnIn strip, wherein the extrusion temperature is 750 degrees, and the N 2 Protect. The strip width is 30mm and the thickness is 20mm.

[0052] In the third step, the AgSnIn strip is ground and polished, and the grinding brush is a resin brush.

[0053] The 4th step, with the strip after the 3rd step process, carry out two-layer cold compounding, the composite front layer is AgSnIn layer, stock thickness 20mm; Another layer of AgSn20 layer (Ag content 80wt%), stock thickness 1.74mm (according to The thickness of the finished product requ...

Embodiment 2

[0060] To prepare Ag(80)SnO 2 -In 2 o 3 / AgSn25 and Ag(80)SnO 2 -In 2 o 3 / AgZn30 electrical contact material as an example

[0061] In the first step, Ag ingots, Sn ingots, In ingots, additive Cu and Ni elements are melted and ingot-cast. Wherein the content of Ag is 83.5wt%, the content of Sn is 10.5wt%, the content of In is 5wt%, the additive Cu is 0.5wt%, and Ni is 0.5wt%.

[0062] In the second step, the alloy ingot obtained in the first step is extruded and processed into an AgSnIn strip or plate, wherein the extrusion temperature is 550 degrees, protected by charcoal; the thickness of the plate is 18mm.

[0063] In the third step, the surface of the AgSnIn strip or plate is ground and polished, and a steel wire brush is used for the grinding brush. This step can also be omitted.

[0064] The fourth step is to process the treated strip or plate with two layers of thermal composite processing, wherein the temperature is 500 degrees, and the temperature is N 2 Pro...

Embodiment 3

[0071] To prepare Ag(88)SnO 2 -In 2 o 3 / AgSn15 and Ag(80)SnO 2 -In 2 o 3 / AgZn15 electrical contact material as an example

[0072] In the first step, Ag ingots, Sn ingots, In ingots, and additive Zn elements are melted and ingot-cast. The content of Ag is 89.5wt%, the content of Sn is 5.5wt%, the content of In is 4.5wt%, and the additive Zn is 0.5wt%.

[0073] In the second step, the alloy ingot obtained in the first step is forged to be processed into an AgSnIn plate, which is forged at 750 degrees, protected by charcoal, and the thickness of the plate is 18mm.

[0074] In the third step, the surface of the AgSnIn plate is ground and polished, and a steel wire brush is used for the grinding brush.

[0075] The fourth step is to carry out two-layer cold compounding of the processed plate. The previous layer of compounding is an AgSnIn layer with a stock thickness of 18mm; the other layer of AgSn15 layer (Ag content 85wt%) and a stock thickness of 6mm (according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com