Method for preparing fluorocarbon material on large scale

A technology of carbon fluoride and nano-carbon materials, which is applied in the direction of carbon fluoride, active material electrodes, electrical components, etc., can solve problems such as low conductivity, poor rate performance, and impact on applications, and achieve high specific power characteristics and increase power performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

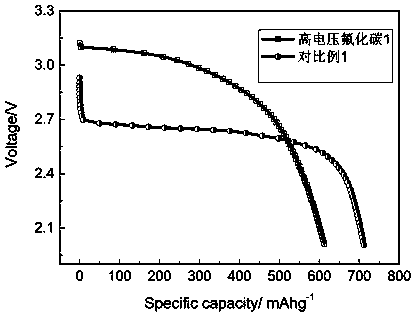

[0021] Put 80g of glucose (C6H12O6) into a tube furnace, pass through argon gas, heat 80g of glucose (C6H12O6) to 400°C under the protection of argon atmosphere, keep it for 1h, and then quench to room temperature to obtain a structure with defects and a particle size distribution It is: d50=100nm nano-carbon material, wherein the carbon content is 80wt.%, the oxygen content is 10wt.%, and the hydrogen content is 10wt.%. The prepared carbon material is put into the fluorination equipment, and the fluorine gas content is 5wt.%. , a fluorine-containing gas with an argon content of 95wt.%, was kept at a pressure of 100 KPa, and reacted at 300°C for 11 h to obtain a fluorinated carbon material with a fluorine content of 50%.

Embodiment 2

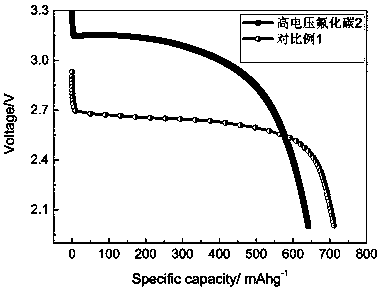

[0023] Put 90g of sucrose (C12H22O11) into a tube furnace, pass through helium, heat 100g of sucrose (C12H22O11) to 450°C under the protection of helium atmosphere, keep it for 1h, and then quench it to room temperature to obtain a structure with defects and a particle size distribution It is: d50=90nm nano-carbon material, wherein the carbon content is 83wt.%, the oxygen content is 8wt.%, and the hydrogen content is 9wt.%. The prepared carbon material is put into the fluorination equipment, and the fluorine gas content is 6wt.%. , a fluorine-containing gas with a helium content of 94wt.%, maintained at a pressure of 110 KPa, and reacted at 400 °C for 11 h to obtain a fluorinated carbon material with a fluorine content of 52%.

Embodiment 3

[0025] Put 100g of glucose (C6H12O6) into a tube furnace, feed nitrogen, heat 100g of glucose (C6H12O6) to 500°C under the protection of nitrogen atmosphere, keep it warm for 1.5h, and then quench to room temperature to obtain a defect structure with a particle size distribution of : d50=80nm nano-carbon material, wherein the carbon content is 85wt.%, the oxygen content is 7wt.%, and the hydrogen content is 8wt.%. The prepared carbon material is put into the fluorination equipment, and the fluorine gas content is 7wt.%. A fluorine-containing gas with a nitrogen content of 93wt.% was kept at a pressure of 120 KPa and reacted at 450 °C for 12 h to obtain a fluorinated carbon material with a fluorine content of 54%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com