Graphene porcelain moxibustion composite energy-saving material and its preparation method and application

A technology of energy-saving materials and composite materials, which is applied in the field of graphene porcelain moxibustion composite energy-saving materials and its preparation, can solve the problems of large operating costs, slow heating of groove beds, and inconvenience for health care shop operators, and achieve enhanced heat storage performance, Enhance the temperature raising speed and improve the effect of heat storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

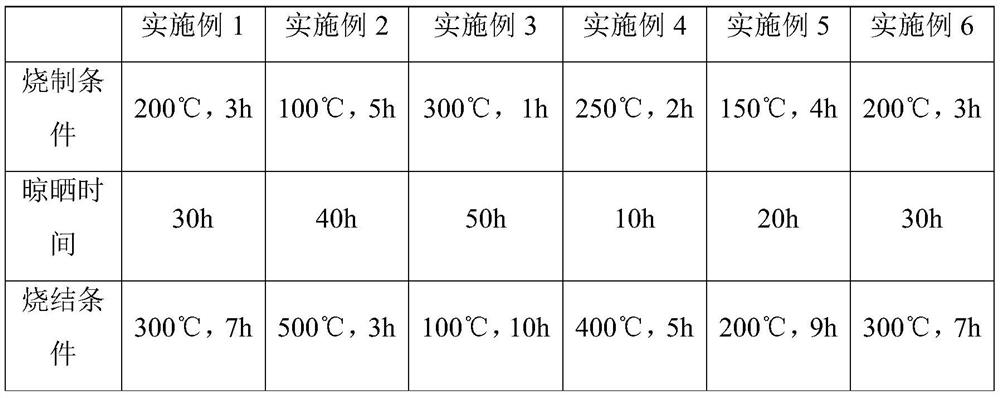

Embodiment 1-6

[0042] The composition of the graphene porcelain moxibustion composite energy-saving material is shown in Table 1.

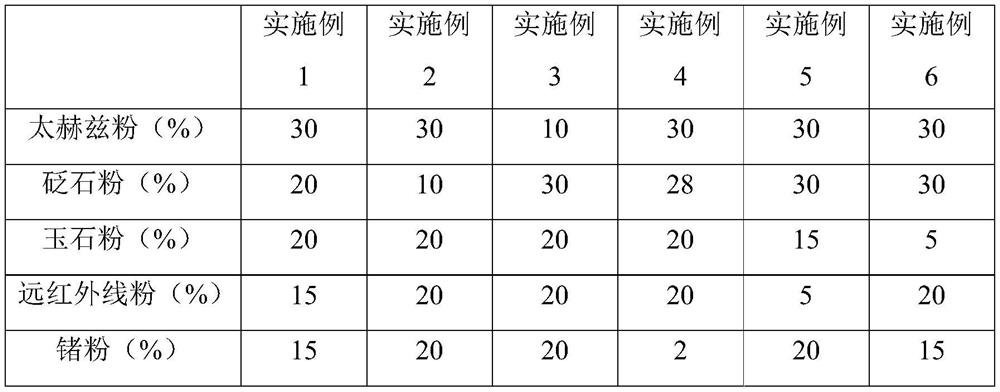

[0043] The material composition of the heat storage material is shown in Table 2.

[0044] The raw material composition of high-frequency materials is shown in Table 3.

[0045] The raw material composition of the antibacterial material is shown in Table 4.

[0046] The aperture material is activated carbon powder.

[0047] The bonding material is sodium metalline.

[0048] The preparation method is composed of the following steps:

[0049] 1) First, mix the kaolin, seafubbles and alumina, ground to a particle size of 100-500 mesh, and prepare a composite material A;

[0050] 2) Mix the graphene with the composite A, baked by 1-5 hours at 100-300 ° C, ground to 50-500 mesh, and prepared composite B;

[0051] 3) Mix the high-frequency material with the antibacterial material to ground to a particle size of 100-500 mesh, and prepare a composite material C;

[0052] 4)...

Embodiment 1

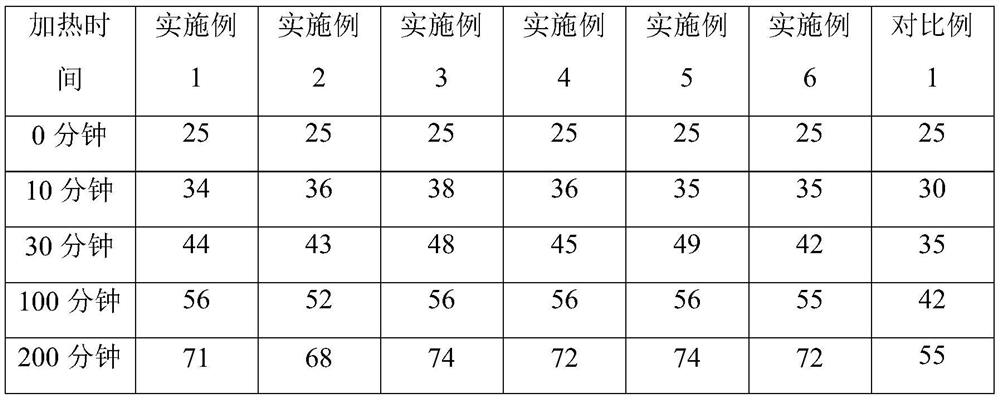

[0086] Example 1 The amount of material consumption was 25.6 degrees.

[0087] The ratio 1 material consumption is 32.7 degrees.

[0088] In summary, the material of Example 1 is 20% more than the comparative example 1 material.

[0089] 5. About antibacterial antibacterial properties

[0090] Example 1 The antibacterial ratio of E. coli was 99.6%, which was 99.4% to the antibacterial ratio of S. aureus.

Embodiment 2

[0091] Example 2 The antibacterial ratio of E. coli was 99.7%, and the antibacterial ratio of S. aureus was 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com