Method for preparing ceramic through 3D printing forming based on modified Na2SiO3 binder

A 3D printing and ceramic preparation technology, applied in the field of 3D printing applications, can solve problems such as limited product strength improvement, environmental pollution, and loss of structural collapse strength of 3D printed products, so as to improve compressive strength, reduce environmental pollution, and solve Effect of Loss of Structural Collapse Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

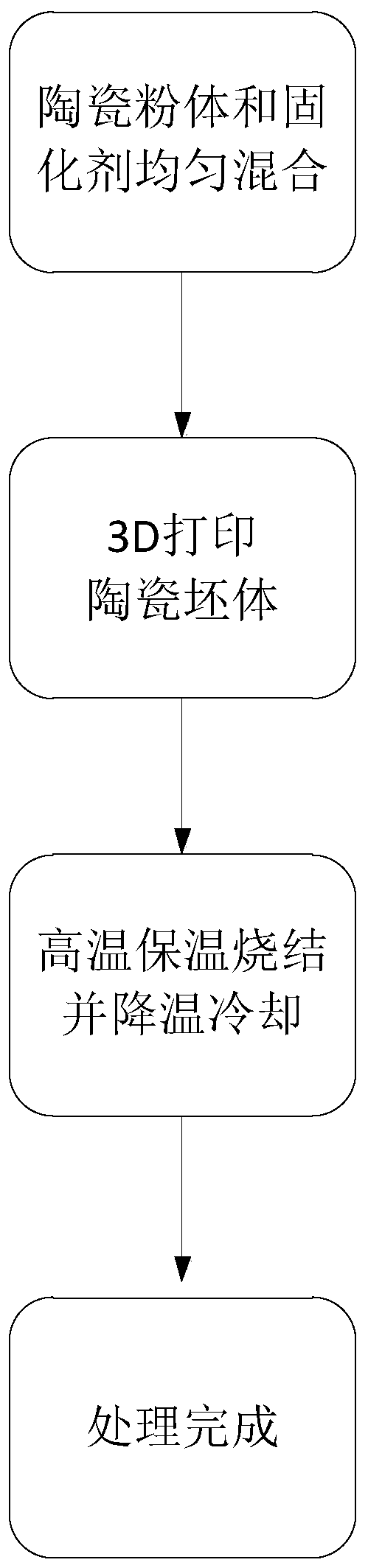

[0026] Such as figure 1 : A ceramic preparation method based on modified sodium silicate binder 3D printing, comprising the following steps:

[0027] S1: powder treatment, uniformly mix the curing agent and the oxide ceramic powder; the curing agent can be a solid curing agent or a liquid curing agent, and the amount of the curing agent is 0.16% to 0.75% of the weight of the oxide ceramic powder.

[0028] Among them, the solid curing agent mainly includes but is not limited to dicalcium silicate, Portland cement, or a combination of two;

[0029] The liquid curing agent mainly includes one or more combinations of glycerin monoacetate, glycerin diacetate, and glycerin triacetate;

[0030] Alternatively, the liquid curing agent includes, but is not limited to, one or more combinations of ethylene glycol diacetate, diethylene glycol diacetate, ethylene glycol propionate, propylene carbonate, and fluosilicic acid.

[0031] The oxide ceramics include any one of silica ceramics, a...

Embodiment 1

[0037] S1: powder treatment, Al 2 o 3 The curing agent composed of ceramic powder and a mixture of glycerin monoacetate, glycerin diacetate and triacetin is mixed evenly, and the addition amount of the curing agent mixture is Al 2 o 3 0.3% by weight of ceramic powder.

[0038] S2: 3D printing ceramic products, with Al in S1 2 o 3 The ceramic mixed powder is used as the matrix, and the 3D printed ceramic green body is obtained after printing and sand cleaning. The amount of sodium silicate binder added is Al 2 o 3 3% by weight of ceramic mixed powder.

[0039] S3: sintering, heat the 3D printed ceramic green body in step S2 at a temperature of 1680° C. for 2 hours, and cool down to obtain a 3D printed alumina ceramic product.

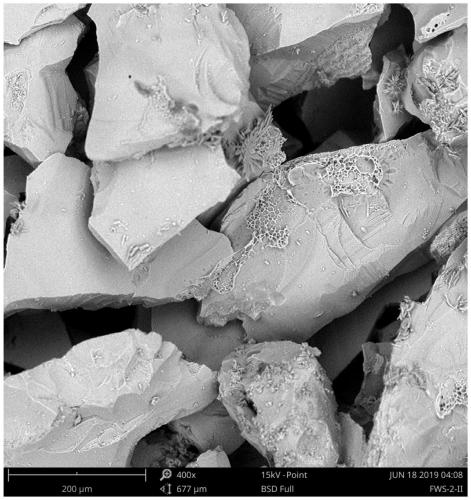

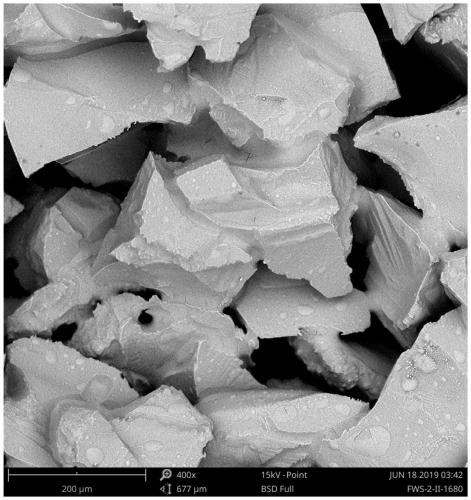

[0040] Such as figure 2 Shown: This picture is 3D printing Al 2 o 3 The scanning electron microscope picture of the green body before sintering shows that there are many and large gaps on the surface before sintering, and the cementation effec...

Embodiment 2

[0043] S1: powder treatment, Al 2 o 3 The curing agent composed of ceramic powder and a mixture of glycerin monoacetate, glycerin diacetate and triacetin is mixed evenly, and the addition amount of the curing agent mixture is Al 2 o 3 0.3% by weight of ceramic powder.

[0044] S2: 3D printing ceramic products, with Al in S1 2 o 3 The ceramic mixed powder is used as the matrix, and the 3D printed ceramic green body is obtained after printing and sand cleaning. The amount of sodium silicate binder added is Al 2 o 3 3% by weight of ceramic mixed powder.

[0045] S3: sintering, heat the 3D printed ceramic green body in step S2 at a temperature of 1630° C. for 2 hours, and obtain 3D printed alumina ceramic products after cooling down.

[0046] 3D printing Al after processing by the method of this example 2 o 3 The compressive strength of ceramic products is 8.85MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com