Preparation method and application of ultra-smallpalladium base alloy material

A technology based on alloys and ultra-small palladium, applied in the field of nanomaterials, can solve the problems that the soft landing method cannot be applied to large-scale production, and the contact between the substrate and the active site of the catalyst is difficult, so as to facilitate the application of catalytic research and facilitate industrial production , the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a method for preparing an ultra-small palladium-based alloy material, comprising: mixing a nitrogen-doped porous carbon material, a palladium salt and a metal salt in a solvent, and obtaining the mixture after removing the solvent; Calcined in the atmosphere to obtain ultra-small palladium-based alloy materials.

[0039] This application has prepared a palladium-based ultra-small alloy catalyst by means of impregnation and heat treatment. The alloy cluster restricts the growth of particles through the coordination of metal atoms and nitrogen atoms on the support, and at the same time improves the stability of the catalyst. In addition, the abundant pores on the support Structure also plays a key role in inhibiting particle sintering.

[0040] The present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0041] Wherein, the content of nitrogen element in the nitrogen-doped porous carbon...

Embodiment 1

[0057] Mix 2.50g of cyclohexanone octawater and 1.44g of urea, grind it thoroughly, add 15.0g of zinc chloride, grind it fully, move it to a quartz boat, and raise the temperature to 90~ at a rate of 5°C / min under nitrogen protection Form a eutectic flux at 100°C, keep it warm for 1-2 hours, then raise the temperature to 600°C at a heating rate of 2.5°C / min and keep it warm for 3 hours, use 1M HCl solution to stir at 80°C for 6 hours, filter with suction, and dry to get nitrogen-doped porous carbon material. The mass fraction of nitrogen in the obtained nitrogen-doped porous carbon material reaches more than 10%.

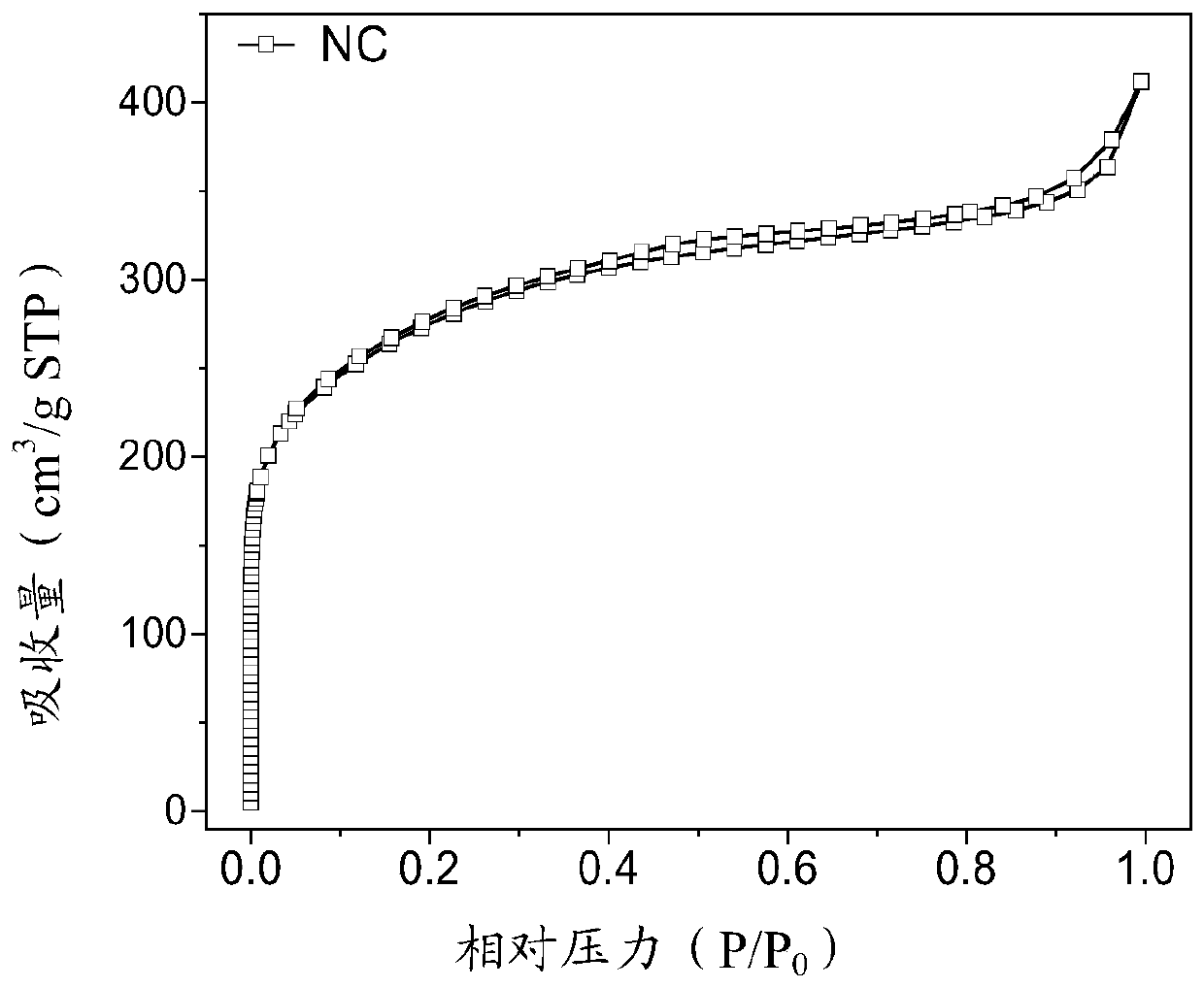

[0058] figure 1 It is the nitrogen adsorption-desorption curve and pore size distribution diagram of the nitrogen-doped porous carbon material obtained in Example 1 of the present invention. BET specific surface area reaches >900m 2 / g, containing a large number of micropores and mesopores.

Embodiment 2

[0060] Mix 50.0 mg of nitrogen-doped porous carbon material obtained in Example 1 above with palladium chloride solution containing 1.25 mg of Pd, then add lead nitrate solution so that the atomic ratio of Pd and Pb is 1:2, and finally add water to dilute to make The total volume of the mixed solution was kept at 40 ml. The mixed solution obtained above was sonicated for 1 hour, and then stirred at room temperature for 12 hours, so that the precursor and the carbon carrier were fully mixed; Medium reduction, the heating rate is 5°C / min, the temperature is raised to 500°C, and the temperature is kept for 2h. Then cool down to room temperature naturally, and the ultra-small palladium-based alloy material can be obtained.

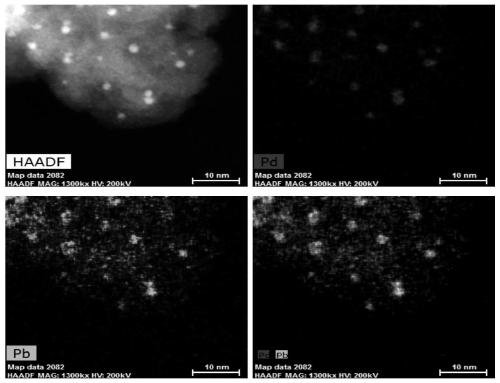

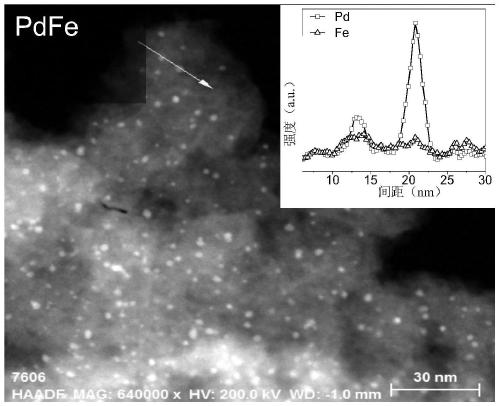

[0061] Utilize the high-angle annular dark field image-scanning transmission electron microscope to analyze the ultra-small palladium-based alloy material obtained in embodiment 2, obtain its HAADF-STEM electron microscope photo and its energy dispersive spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com