Method for preparing GRCop-84 spherical powder based on plasma rotary atomization method

A grcop-84, rotary atomization technology, applied in the field of metal powder metallurgy, to achieve the effect of good fluidity, less inclusions, and low gas volume fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

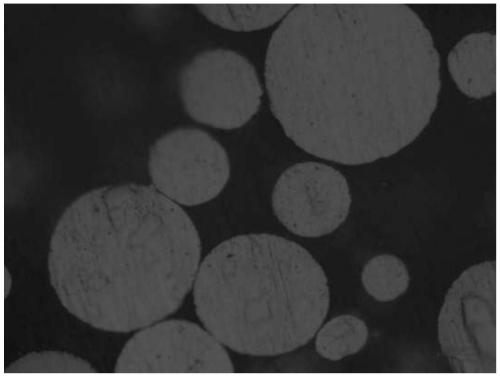

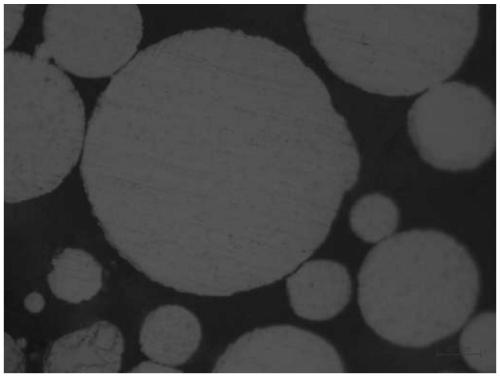

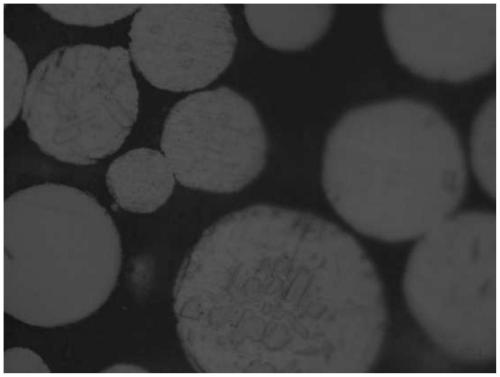

Image

Examples

Embodiment 1

[0024] A method for preparing GRCop-84 spherical powder based on plasma rotary atomization method, is characterized in that, comprises the following steps:

[0025]S1: Select Cr: 5% according to the mass fraction; Nb: 4.5%; Cu: the balance, there is no obvious looseness, shrinkage cavity and other defects on the surface of the bar, and the electrolytic copper plate, chromium block, and niobium block are mixed and placed in the crucible to start melting and pouring After forging, a bar blank with a relative density ≥ 90% is obtained; the electrolytic copper plate, chromium block, and niobium block are mixed and smelted, and the prepared bar blank has no looseness, shrinkage cavity, etc. GRCop-84 alloy spherical powder prepared by atomization method has higher sphericity, higher bulk density and better fluidity;

[0026] S2: GRCop-84 rods with a diameter of 50 mm, a length of 800 mm, and a surface roughness of 1.6 μm are processed by a lathe;

[0027] S3: Put the GRCop-84 rod a...

Embodiment 2

[0031] A method for preparing GRCop-84 spherical powder based on plasma rotary atomization method, is characterized in that, comprises the following steps:

[0032] S1: Select Cr: 6.5% according to the mass fraction; Nb: 5.8%; Cu: the balance, there is no obvious looseness, shrinkage cavity and other defects on the surface of the bar, and the electrolytic copper plate, chromium block, and niobium block are mixed and placed in the crucible to start melting and pouring After forging, a bar blank with a relative density of 90% is obtained; the electrolytic copper plate, chromium block, and niobium block are mixed and smelted, and the prepared bar blank has no looseness, shrinkage cavity, etc. GRCop-84 alloy spherical powder prepared by chemical method has higher sphericity, higher bulk density and better fluidity;

[0033] S2: GRCop-84 rods with a diameter of 65 mm, a length of 1000 mm and a surface roughness of 1.6 μm are processed by a lathe;

[0034] S3: Put the GRCop-84 rod ...

Embodiment 3

[0038] A method for preparing GRCop-84 spherical powder based on plasma rotary atomization method, is characterized in that, comprises the following steps:

[0039] S1: Select Cr: 7% according to the mass fraction; Nb: 6.5%; Cu: the balance, there is no obvious looseness, shrinkage cavity and other defects on the surface of the bar, and the electrolytic copper plate, chromium block, and niobium block are mixed and placed in the crucible to start melting and pouring After forging, a bar blank with a relative density ≥ 90% is obtained; the electrolytic copper plate, chromium block, and niobium block are mixed and smelted, and the prepared bar blank has no looseness, shrinkage cavity, etc. GRCop-84 alloy spherical powder prepared by atomization method has higher sphericity, higher bulk density and better fluidity;

[0040] S2: GRCop-84 rods with a diameter of 80mm, a length of 1200mm, and a surface roughness of 1.6μm were processed by a lathe;

[0041] S3: Put the GRCop-84 rod a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com