Building dual-layer glass with purification function

A technology of double-layer glass and tempered glass, applied in the direction of glass/slag layered products, lamination, coating, etc., can solve the problems of single function, no performance of purifying air, poor heat insulation effect, etc., and achieve photocatalysis Strong ability, excellent heat insulation effect, good durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

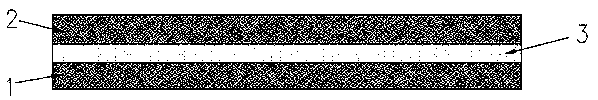

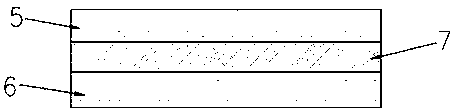

[0024] The 7 components of the photocatalytic coating include 10-20 parts by weight of polyvinyl alcohol, 10-30 parts of nano-titanium dioxide, 5-10 parts of polyoxyethylene polyoxypropylene block copolymer, 2-6 parts of graphene oxide, 2-4 parts of nano activated carbon particles, 2-6 parts of nano magnesia powder, 1-4 parts of nano zirconia powder, 2-5 parts of nano calcium carbonate and 8-14 parts of polymethylphenyl silicone resin.

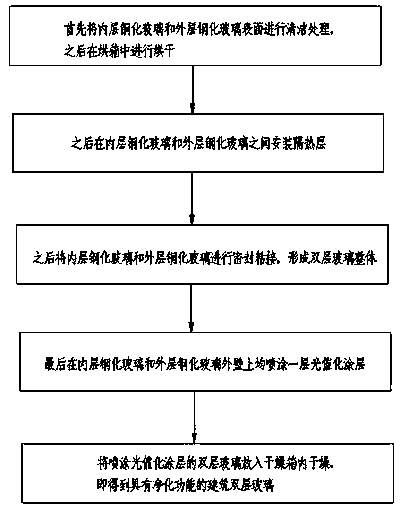

[0025] The manufacturing method of this embodiment includes the following steps:

[0026] A. First, clean the surface of the inner tempered glass and the outer tempered glass, and then dry them in an oven;

[0027] B. After that, install a heat insulation layer between the inner tempered glass and the outer tempered glass;

[0028] C. Afterwards, the inner tempered glass and the outer tempered glass are sealed and bonded to form a double-layer glass as a whole;

[0029] D. Finally, a layer of photocatalytic coating is sprayed on the inner te...

Embodiment 2

[0034] The 7 components of the photocatalytic coating include 10-20 parts by weight of polyvinyl alcohol, 10-30 parts of nano-titanium dioxide, 5-10 parts of polyoxyethylene polyoxypropylene block copolymer, 2-6 parts of graphene oxide, 2-4 parts of nano activated carbon particles, 2-6 parts of nano magnesia powder, 1-4 parts of nano zirconia powder, 2-5 parts of nano calcium carbonate and 8-14 parts of polymethylphenyl silicone resin.

[0035] The manufacturing method of this embodiment includes the following steps:

[0036] A. First, clean the surface of the inner tempered glass and the outer tempered glass, and then dry them in an oven;

[0037] B. After that, install a heat insulation layer between the inner tempered glass and the outer tempered glass;

[0038] C. Afterwards, the inner tempered glass and the outer tempered glass are sealed and bonded to form a double-layer glass as a whole;

[0039] D. Finally, a layer of photocatalytic coating is sprayed on the inner te...

Embodiment 3

[0044] The 7 components of the photocatalytic coating include 10-20 parts by weight of polyvinyl alcohol, 10-30 parts of nano-titanium dioxide, 5-10 parts of polyoxyethylene polyoxypropylene block copolymer, 2-6 parts of graphene oxide, 2-4 parts of nano activated carbon particles, 2-6 parts of nano magnesia powder, 1-4 parts of nano zirconia powder, 2-5 parts of nano calcium carbonate and 8-14 parts of polymethylphenyl silicone resin.

[0045] The manufacturing method of this embodiment includes the following steps:

[0046] A. First, clean the surface of the inner tempered glass and the outer tempered glass, and then dry them in an oven;

[0047] B. After that, install a heat insulation layer between the inner tempered glass and the outer tempered glass;

[0048] C. Afterwards, the inner tempered glass and the outer tempered glass are sealed and bonded to form a double-layer glass as a whole;

[0049] D. Finally, a layer of photocatalytic coating is sprayed on the inner te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com