Attapulgite soil-based inner wall brick with environmental protection function and preparation method thereof

A technology of attapulgite and function, which is applied in the field of attapulgite-based interior wall bricks and its preparation, which can solve the problems of rough preparation method, failure to consider adsorption and reaction, failure to consider the mechanical strength of decorative wall materials, etc., and achieve advanced technology , Strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

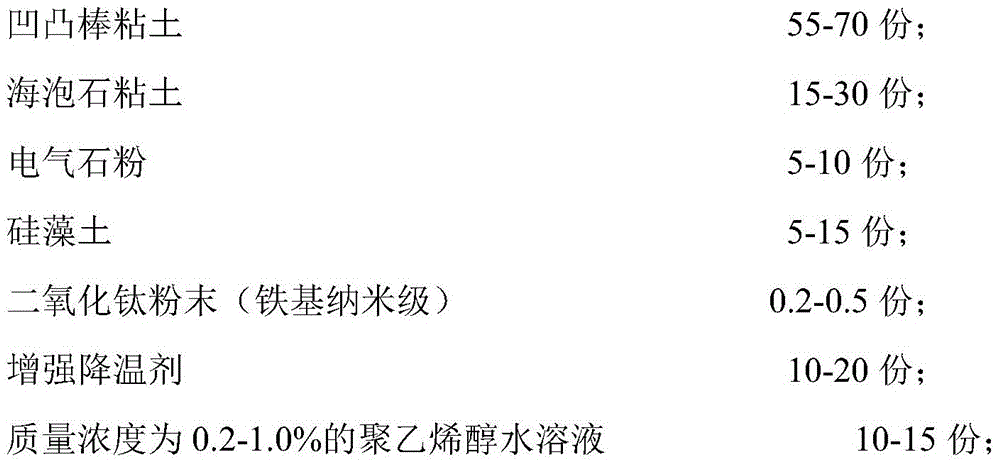

Method used

Image

Examples

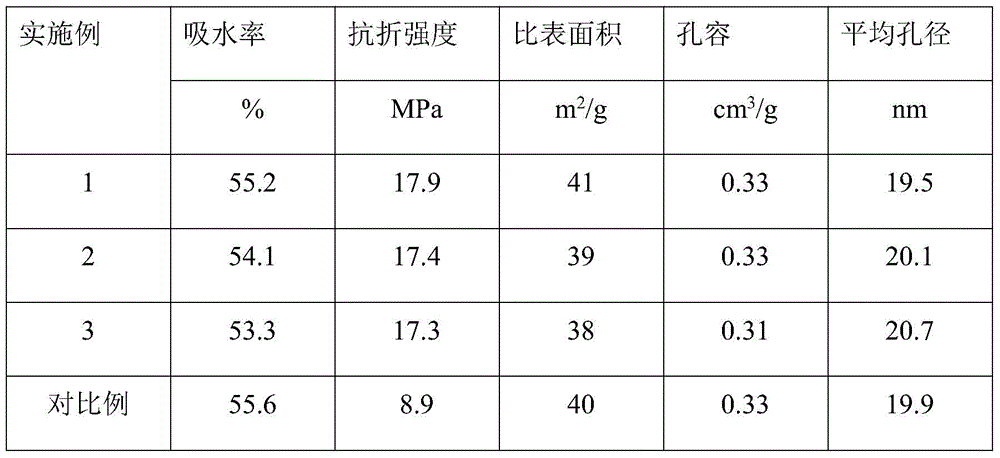

Embodiment 1

[0026] With 65 kilograms of 500 order attapulgite; 15 kilograms of 800 order sepiolite clay; 5 kilograms of 1250 order tourmaline powder; 5 kilograms of 500 order diatomite; According to formula ratio (35 parts of ceramic fiber, 20 parts of water glass, 45 parts of borax ) Prepare 7 kg of enhanced cooling agent and put it into a mixer for dry and full mixing, then add 10-15 kg of polyvinyl alcohol aqueous solution with a mass concentration of 0.2-1.0%, continue stirring to become semi-dry and viscous, and repeatedly extrude through an extruder After pressing, put it into a decorative wall tile mold and press to form it with a press, spray evenly a 1.5% nano-scale iron-based titanium dioxide aqueous solution on the surface of the formed product, and then air dry it for 5-10 hours. Then use a drying oven to dry, the drying temperature is 120° C., and the drying time is 1 hour. Finally, calcination is carried out, and the calcination temperature and time are controlled as follows...

Embodiment 2

[0028] With 60 kilograms of 500 order attapulgite; 15 kilograms of 800 order sepiolite clay; 5 kilograms of tourmaline powder of 1250 orders; 10 kilograms of 500 order diatomites; ) Prepare 7 kg of enhanced cooling agent and put it into a mixer for dry and full mixing, then add 10-15 kg of polyvinyl alcohol aqueous solution with a mass concentration of 0.2-1.0%, continue stirring to become semi-dry and viscous, and repeatedly extrude through an extruder After pressing, put it into a decorative wall tile mold and press it with a press to form it. The surface of the molded product is evenly sprayed with a nano-scale iron-based titanium dioxide aqueous solution with a concentration of 1.5% by mass, and then air-dried for 5-10 hours. Then use a drying oven to dry, the drying temperature is 120° C., and the drying time is 1 hour. Finally, calcination is carried out, and the calcination temperature and time are controlled as follows: 250°C, 1 hour; 350°C, 1 hour; 450°C, 1 hour; 585°...

Embodiment 3

[0030] With 55 kilograms of 500 order attapulgite; 15 kilograms of 800 order sepiolite clay; 5 kilograms of 1250 order tourmaline powder; 15 kilograms of 500 order diatomite; According to formula ratio (35 parts of ceramic fiber, 20 parts of water glass, 45 parts of borax ) Prepare 7 kg of enhanced cooling agent and put it into a mixer for dry and full mixing, then add 10-15 kg of polyvinyl alcohol aqueous solution with a mass concentration of 0.2-1.0%, continue stirring to become semi-dry and viscous, and repeatedly extrude through an extruder After pressing, put it into a decorative wall tile mold and press to form it with a press, spray evenly a 1.5% nano-scale iron-based titanium dioxide aqueous solution on the surface of the formed product, and then air dry it for 5-10 hours. Then use a drying oven to dry, the drying temperature is 120° C., and the drying time is 1 hour. Finally, calcination is carried out, and the calcination temperature and time are controlled as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com