A kind of high-conductivity paste, preparation method and application thereof, lithium battery separator and lithium battery

A lithium battery separator, high conductivity technology, applied in the direction of lithium batteries, non-aqueous electrolyte batteries, battery pack components, etc., can solve the problems of poor liquid retention, low liquid absorption rate of the diaphragm, low ion conductivity, etc., to improve the battery life Hydraulic power, improved ionic conductivity, and good affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

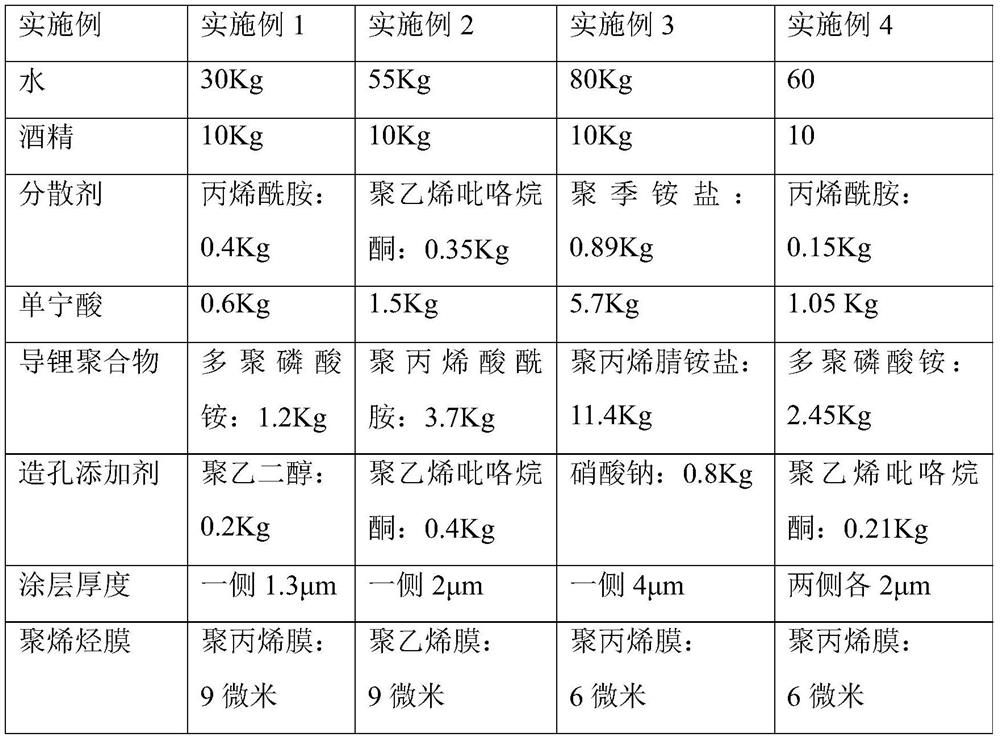

Embodiment 1

[0036] High electrical conductive slurry, including 30kg water, 10kg alcohol, 0.4kg dispersant (acrylamide), 0.6kg tannic acid, 1.2kg lithium polymer (ammonium polyphosphate) and 0.2kg pore additive (PE Diol).

[0037] The high electrical biller is prepared by the following method:

[0038] Step 1, mix the water and alcohol to give a solvent, then add a dispersant, stirred in a stirrer for 10 min to mix well to obtain a mixed solution;

[0039] Step 2, mix the tannic acid, the lithium polymer, and the aperture additive, resulting in a mixed solid, adding the mixing solution in the mixer of step 1, continues to stir 30 min to obtain a mixing system;

[0040] Step 3, remove the mixing system obtained by the step 2 to the introduction sander sand mill sand mill, resulting in the high electrical scale.

[0041] A lithium battery diaphragm comprising a polyolefin base film and a coating coated on one side of the polyolefin base film, wherein the polyolefin base film has a thickness of ...

Embodiment 2

[0046] High electrical conductive slurry, including 55kg water, 10kg alcohol, 0.35kg dispersant (polyvinylpyrrolidone), 1.5kg tannic acid, 3.7kg lithium polymer (polyacrylate) and 0.4 kg of pore additive (polyethylene) Pyrrolidone).

[0047] The high electrical biller is prepared by the following method:

[0048] Step 1, mix the water and alcohol to give a solvent, then add a dispersant, stirred in a stirrer for 10 min to mix well to obtain a mixed solution;

[0049] Step 2, mix the tannic acid, the lithium polymer, and the aperture additive, resulting in a mixed solid, adding a mixed solution in the mixer of step 1, continues to stir 40min, resulting in a mixing system;

[0050] Step 3, remove the mixing system obtained by the step 2 to the introduction of sand mill sand mill, resulting in the high electrical biller.

[0051] A lithium battery diaphragm comprising a polyolefin base film and a coating coated on one side of the polyolefin base, wherein the polyolefin base film has a ...

Embodiment 3

[0056] High electrical conductive slurry, including 80kg water, 10kg alcohol, 0.89kg dispersant (poly quarantine salt), 5.7kg tannic acid, 11.4kg lithium polymer (polypropylene ammonium salt) and 0.8kg pore additive (Sodium nitrate).

[0057] The high electrical biller is prepared by the following method:

[0058] Step 1, mix the water and alcohol to give a solvent, then add a dispersant, stirred in a stirrer for 10 min to mix well to obtain a mixed solution;

[0059] Step 2, mix the tannic acid, the lithium polymer, and the aperture additive, resulting in a mixed solid, adding a mixed solution in the mixer of step 1, continued to stir 60 min to obtain a mixed system;

[0060] Step 3, remove the mixing system obtained by the step 2 to the introduction sander sand mill sand mill, resulting in the high electrical scale.

[0061] A lithium battery diaphragm comprising a polyolefin base film and a coating coated on one side of the polyolefin substrate, wherein the polyolefin base film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com