Electrolytic manganese slag containing road anti-cracking cement stabilized macadam material, and preparation method thereof

A technology of electrolytic manganese slag and water stabilization layer, which is applied in the field of cement materials, can solve the problems of non-environmental protection of the preparation method, achieve the effects of reducing production costs, improving rheology, and preventing temperature shrinkage stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

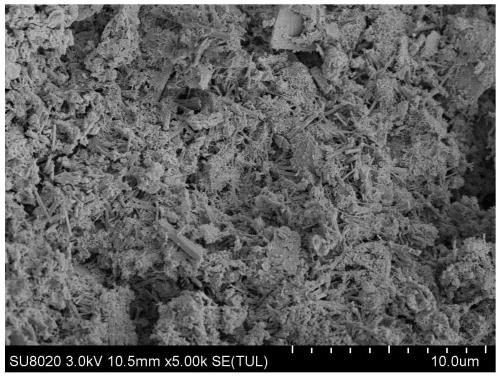

[0044] Preparation Example 1 The composite phase change material is self-made, and its preparation method comprises the following steps:

[0045] 1. Heat and impregnate 1 part of expanded graphite in 15 parts of paraffin wax in a water bath at 80°C, stir and absorb for 2 hours, filter, dry, and grind to a particle size of 1-5mm for later use;

[0046] 2. Add 50 parts of deionized water, 20 parts of melamine and formaldehyde in a molar ratio of 1:3 to the reactor, adjust the pH to 8-9 with 10wt% sodium carbonate solution, stir at 70°C for 10-60min, and obtain a transparent pre- Polymer solution, spare;

[0047] 3. Mix the material obtained in step 1 with the prepolymer solution obtained in step 2, adjust the pH to about 4.5 with acetic acid solution, continue to stir and react at 50°C for 4 hours, adjust the pH to neutral, filter, wash with absolute ethanol, and dry to obtain Melamine coated paraffin / expanded graphite composite.

preparation example 2

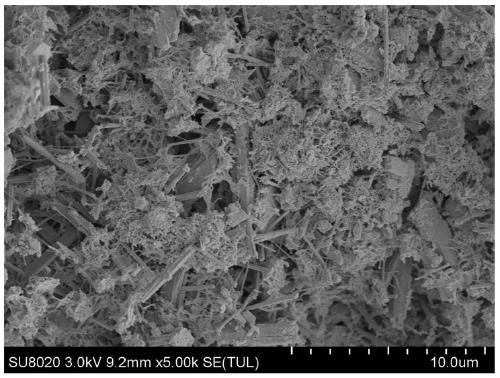

[0049] All the other are identical with preparation example 1, and difference is that paraffin is 20 parts.

preparation example 3

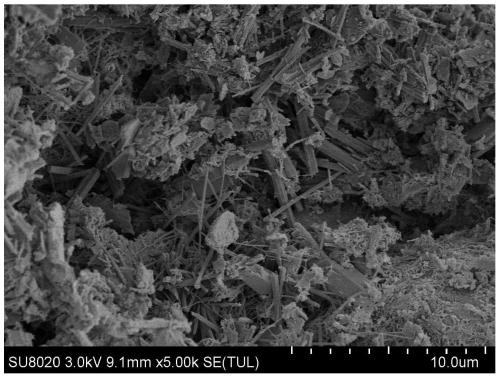

[0051] All the other are the same as Preparation Example 1, except that the paraffin wax is 10 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com