Polysiloxane aerogel composite material for efficient water evaporation and preparation method and application thereof

A technology of polysiloxane and composite materials, which is applied in general water supply saving, chemical instruments and methods, seawater treatment, etc., can solve the problems of ineffective use of latent heat of evaporation and condensation, low utilization rate of solar energy, complicated devices, etc., and it is not easy to achieve The effects of enrichment and crystallization, stable shape, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

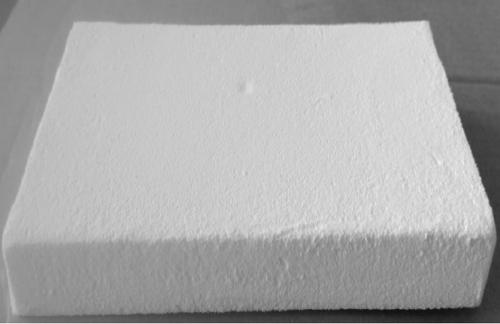

[0038] Mix 1 ml tetraethyl silicate, 1 ml deionized water, and 10 ml ethanol evenly, then add 1M ammonia water to adjust the pH of the above mixed solution to 7.5; then soak the commercially available hydrophobic polysiloxane airgel in the above solution, after soaking fully, at 60~120 o C drying for 20-30 hours to obtain hydrophilic polysiloxane airgel.

[0039] Cesium-doped tungsten trioxide nano-powder, water, polypropylene resin, dispersant BYK358N and UV absorber BYK1130 are configured as a resin slurry with a solid content of 0.9%; cesium-doped tungsten trioxide nano-powder, water, polypropylene The mass ratio of acrylic resin, dispersant BYK358N and UV absorber BYK1130 is 0.1:6:4:0.05:1. After stirring the prepared slurry evenly, store it away from light.

[0040] Immerse the hydrophilic modified polysiloxane airgel in the resin slurry, after fully adsorbed, at 40~120 oC drying for 1~4h, the polysiloxane airgel composite material for high-efficiency water evaporation...

Embodiment 2

[0042] Put the airgel in a tube furnace, firstly vacuumize and then feed nitrogen, the heating rate is 2°C / min, and the temperature is kept at 800°C for 2h to obtain the hydrophilic polysiloxane airgel.

[0043] Cesium-doped tungsten trioxide nanopowder, water, polypropylene resin, dispersant BYK358N and UV absorber BYK1130 are configured as a resin slurry with a solid content of 1.2%; cesium-doped tungsten trioxide nanopowder, water, polypropylene The mass ratio of acrylic resin, dispersant BYK358N and UV absorber BYK1130 is 0.1:4:3:0.01:1. After stirring the prepared slurry evenly, store it away from light.

[0044] Immerse the hydrophilic modified polysiloxane airgel in the resin slurry, after fully adsorbed, at 40~120 o C drying for 1~4h, the polysiloxane airgel composite material for high-efficiency water evaporation can be obtained.

Embodiment 3

[0046] Mix 1 ml tetraethyl silicate, 1 ml deionized water, and 10 ml ethanol evenly, then add 1.2M ammonia water to adjust the pH of the above mixed solution to 10; then soak the commercially available hydrophobic polysiloxane airgel in In the above solution, after fully soaking, at 60~120 o C drying for 20-30 hours to obtain hydrophilic polysiloxane airgel.

[0047] Cesium-doped tungsten trioxide nanopowder, water, polypropylene resin, dispersant BYK358N and UV absorber BYK1130 were configured as a resin slurry with a solid content of 2.4%; cesium-doped tungsten trioxide nanopowder, water, polypropylene The mass ratio of acrylic resin, dispersant BYK358N and UV absorber BYK1130 is 0.2:4:3:0.01:1. After stirring the prepared slurry evenly, store it away from light.

[0048] Immerse the hydrophilic modified polysiloxane airgel in the resin slurry, after fully adsorbed, at 40~120 o C drying for 1~4h, the polysiloxane airgel composite material for high-efficiency water evapora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com