Light weather resistant optical grade PET rigid film

An optical-grade, weather-resistant technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as film release, screen separation, and poor weather resistance of films, and achieve low surface energy, easy internal rotation, and small overall thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Add 1 part of polytetrafluoroethylene and 1 part of organosilane to 35 parts of UV curing hardening solution and stir evenly, then add 0.4 part of montmorillonite to the stirring solution and continue stirring until uniform to prepare a semi-finished coating solution;

[0022] 2) Mix and stir the semi-finished coating solution prepared in step 1) with 1 part of n-hexadecane, 1 part of diiodomethane and 80 parts of distilled water to obtain a coating solution;

[0023] 3) Use a coating machine to transfer the optical-grade PET film from the unwinding unit to the coating unit, and use the mesh roller to coat the coating solution prepared in step 2) on the optical-grade PET film, dry it through the heat drying unit, and pass through The UV curing unit cures and forms a film to produce a light-duty weather-resistant optical-grade PET hard film.

Embodiment 2

[0025] 1) Add 1.2 parts of polytetrafluoroethylene and 1.2 parts of organosilane to 40 parts of UV curing hardening solution for uniform stirring, then add 0.6 parts of montmorillonite to the stirring solution and continue stirring until uniform to prepare a semi-finished coating solution;

[0026] 2) Mix and stir the semi-finished coating solution prepared in step 1) with 1.1 parts of n-hexadecane, 1.1 parts of diiodomethane and 90 parts of distilled water to obtain a coating solution;

[0027] 3) Use a coating machine to transfer the optical-grade PET film from the unwinding unit to the coating unit, and use the mesh roller to coat the coating solution prepared in step 2) on the optical-grade PET film, dry it through the heat drying unit, and pass through The UV curing unit cures and forms a film to produce a light-duty weather-resistant optical-grade PET hard film.

Embodiment 3

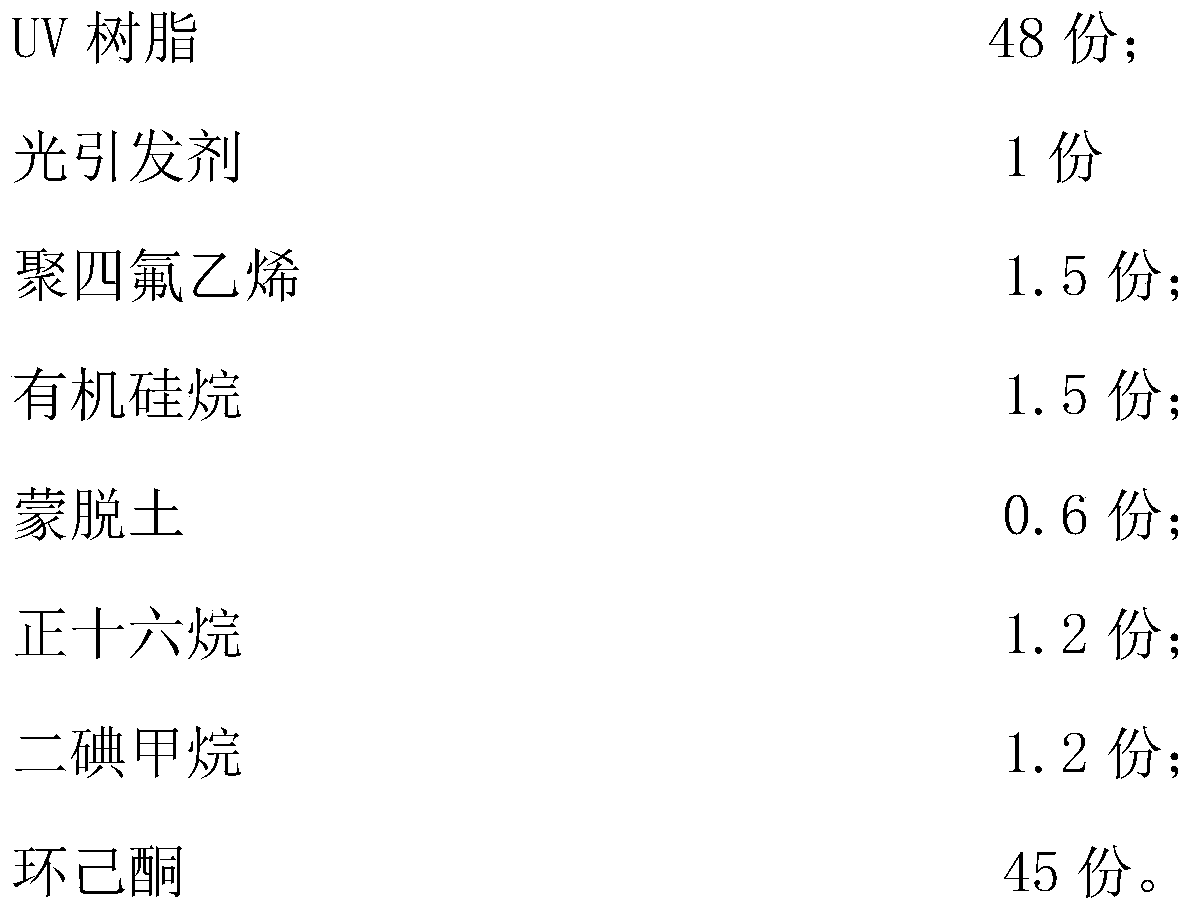

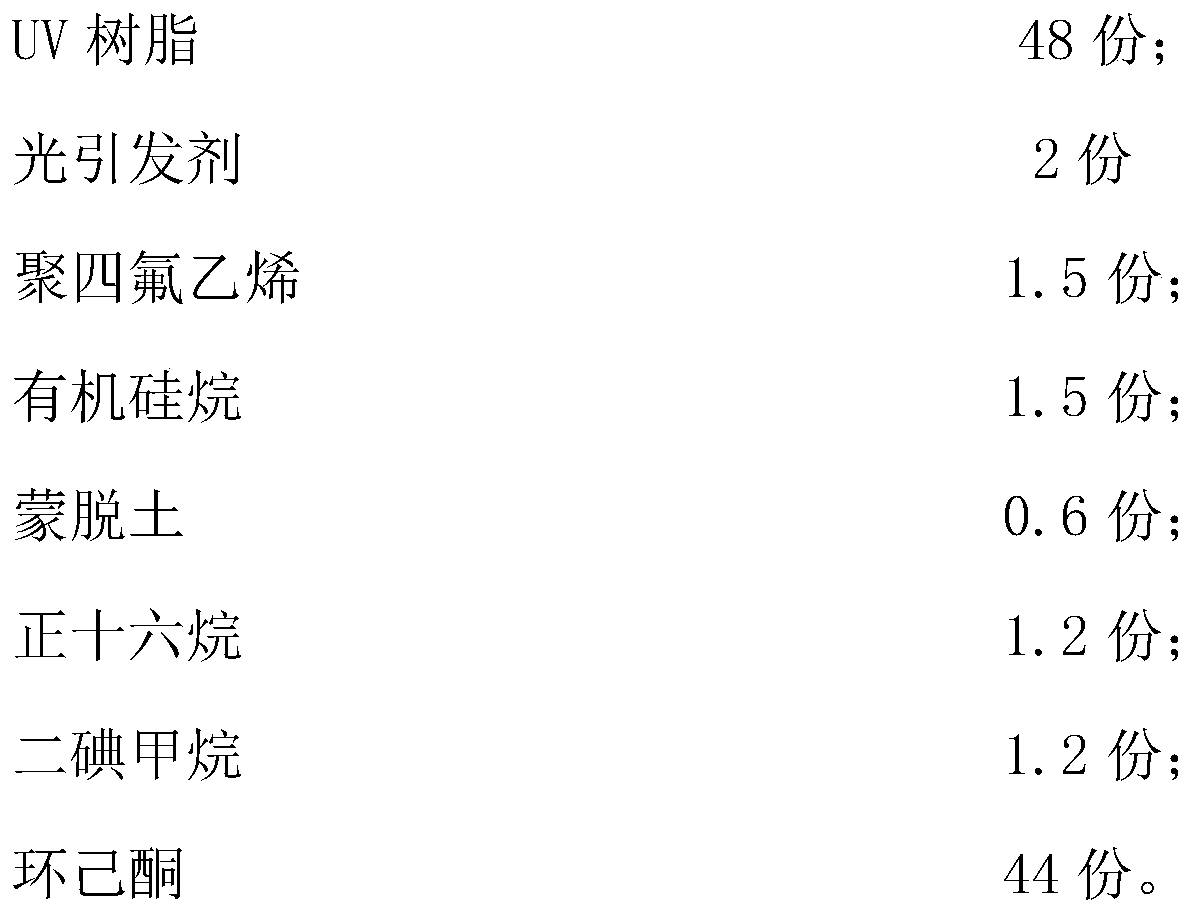

[0029] 1) Add 1.5 parts of polytetrafluoroethylene and 1.5 parts of organosilane to 48 parts of UV resin for uniform stirring, then add 0.6 parts of montmorillonite to the stirring solution and continue stirring until uniform to prepare a semi-finished coating solution;

[0030] 2) Mix and stir the semi-finished coating solution prepared in step 1) with 1.2 parts of n-hexadecane, 1.2 parts of diiodomethane and 45 parts of cyclohexanone to obtain a coating solution;

[0031] 3) Use a coating machine to transfer the optical-grade PET film from the unwinding unit to the coating unit, and use the mesh roller to coat the coating solution prepared in step 2) on the optical-grade PET film, dry it through the heat drying unit, and pass through The UV curing unit cures and forms a film to produce a light-duty weather-resistant optical-grade PET hard film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com