Integrated device and system for propellant waste gas treatment, and use thereof

A technology for waste gas treatment and propellant, which is used in gaseous discharge wastewater treatment, oxidized water/sewage treatment, chemical instruments and methods, etc. It can solve the problem of unsatisfactory waste gas removal effect, inability to meet vehicle requirements, and low reaction efficiency of absorption towers and other problems, to achieve the effect of small occupied space, small gas pressure drop, and elimination of the limitation of height and position relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

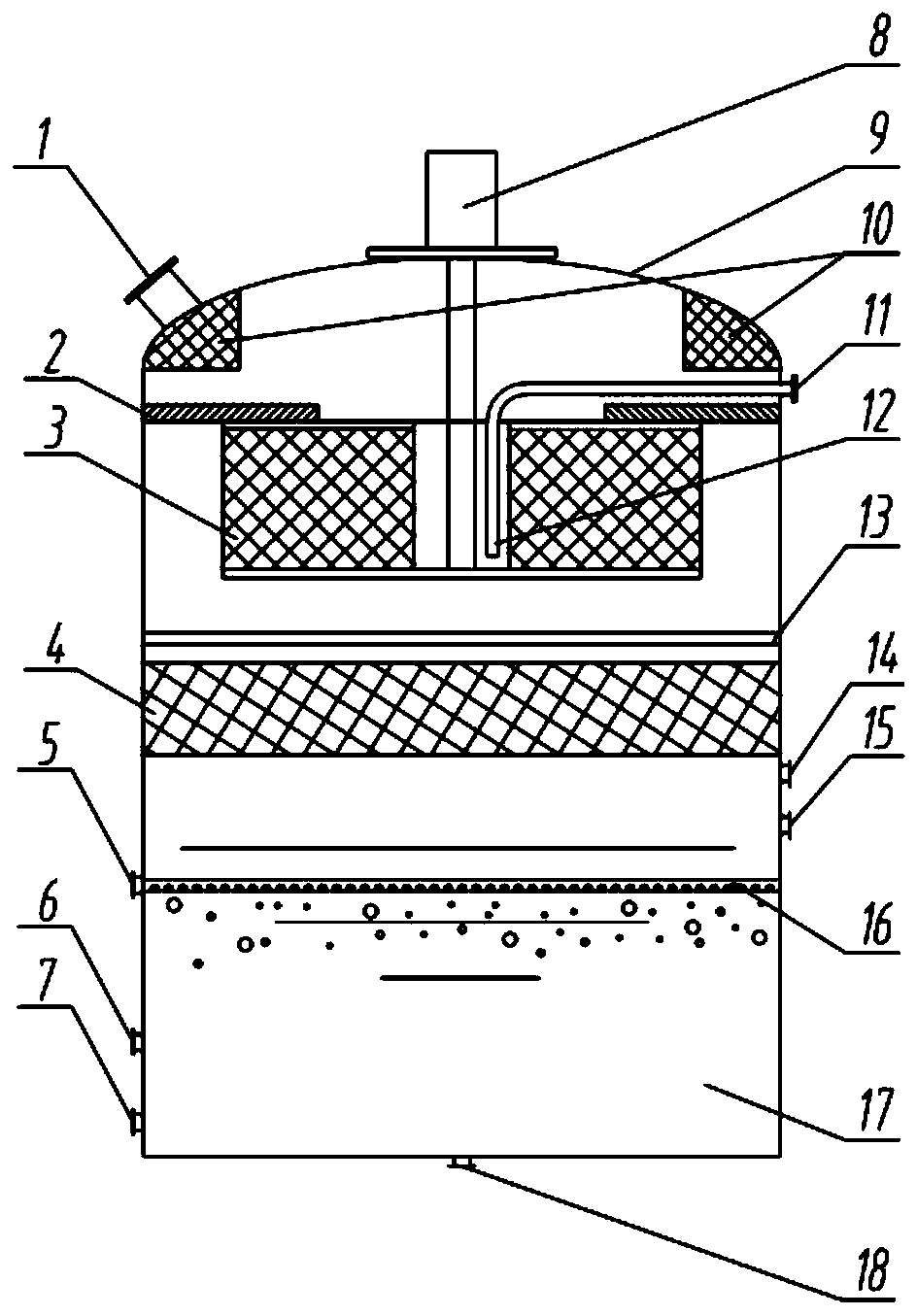

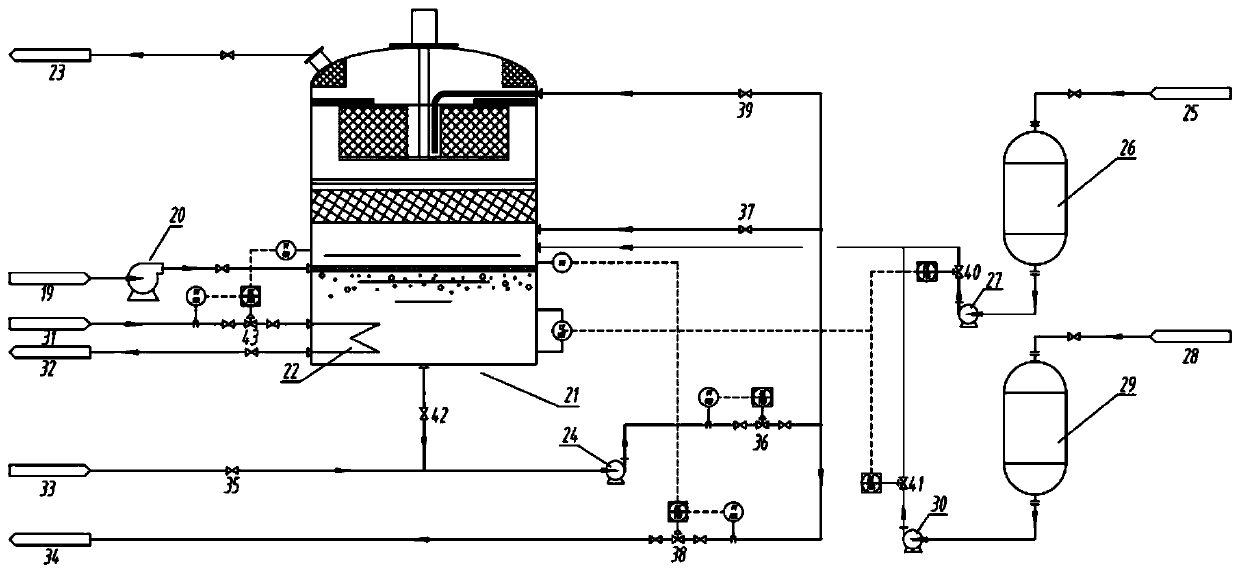

Method used

Image

Examples

Embodiment 1

[0037] The system of the present invention is applied to the treatment of waste gas of propellant dinitrogen tetroxide. The concentration of dinitrogen tetroxide in the exhaust gas is 23000mg / Nm 3 , the flow rate is 1300Nm 3 / h, the supergravity level of the rotating packed bed is 200g, and the flow rate of the absorption liquid entering the rotating packed rotor is 30m 3 / h, the temperature of the absorption liquid is 25°C, the absorption liquid is sodium bicarbonate solution, and the oxidant H 2 o 2 The initial weight percentage is 5%, and the initial pH value of the absorption liquid is 8.6. The measured concentration of nitrogen oxides at the gas outlet is 50.68mg / Nm 3 ;Liquid entrainment is 2.26mg / m 3 ;The content of nitrite in wastewater is 13.69mg / m 3

Embodiment 2

[0039] The system of the present invention is applied to the treatment of waste gas of propellant dinitrogen tetroxide. The concentration of dinitrogen tetroxide in the exhaust gas is 1970mg / Nm 3 , the flow rate is 1500Nm 3 / h, the supergravity level of the rotating packed bed is 300g, and the flow rate of the absorption liquid entering the rotating packed rotor is 40m 3 / h, the temperature of the absorption liquid is 23°C, the absorption liquid is sodium bicarbonate solution, and the oxidant H 2 o 2 The initial weight percentage is 5%, and the initial pH value of the absorption liquid is 8.6. The measured concentration of nitrogen oxides at the gas outlet is 27.31mg / Nm 3 ;Liquid entrainment is 3.68mg / m 3 ;The content of nitrite in wastewater is 9.28mg / m 3 .

Embodiment 3

[0041] The system of the present invention is applied to the treatment of propellant unsymmetrical dimethylhydrazine waste gas. The concentration of unsymmetrical dimethylhydrazine in the exhaust gas is 19800mg / Nm 3 , the flow rate is 1100Nm 3 / h, the supergravity level of the rotating packed bed is 300g, and the flow rate of the absorption liquid entering the rotating packed rotor is 25m 3 / h, the temperature of the absorption liquid is 23°C, the absorption liquid is a sulfuric acid solution, and the oxidant H 2 o 2 The initial weight percentage is 5%, and the initial pH value of the absorption liquid is 2.4. The measured concentration of unsymmetrical dimethylhydrazine at the gas outlet is 19.66mg / Nm 3 ;Liquid entrainment is 1.98mg / m 3 ;The content of nitrite in wastewater is 11.36mg / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com