Preparation method for controllable degradation type zinc-magnesium gradient material

A gradient material, zinc-magnesium technology, applied in the preparation and application of medical biomaterials, can solve the problem that it is difficult to meet the diversity of degradable implant materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with accompanying drawing:

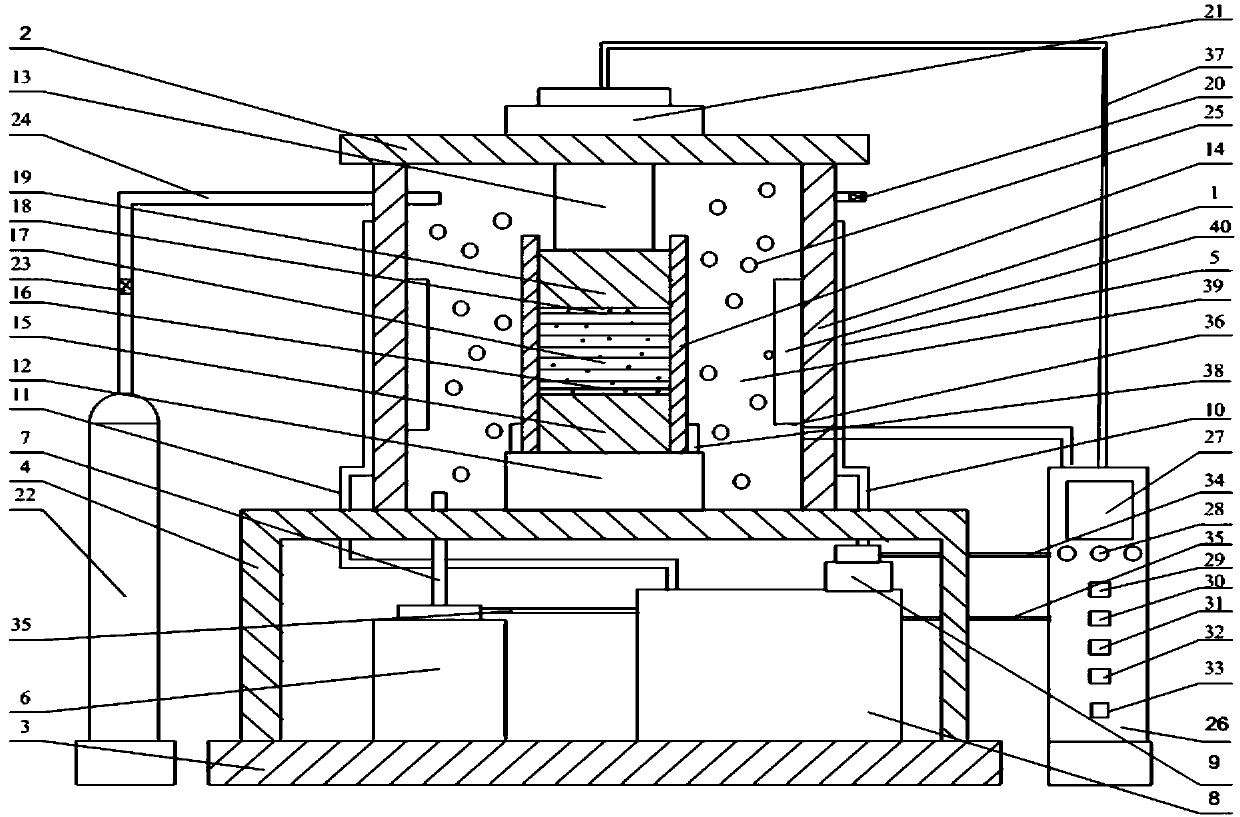

[0071] figure 1 As shown in ., it is the state diagram of spark plasma sintering of magnesium-zinc gradient mixed powder. It is necessary to connect all parts correctly and operate in sequence.

[0072] Quantities of chemicals used in preparation determined in pre-set ranges in grams, milliliters, microns, moles / liter, centimeters 3 is the unit of measurement.

[0073] The sintering of the magnesium-zinc gradient mixed powder is carried out in the spark plasma sintering furnace protected by argon gas, and is completed during the heating process of the discharge plasma;

[0074] The discharge plasma sintering furnace is vertical, including a vacuum sintering furnace 1, the lower part of the vacuum sintering furnace 1 is a base 3, the upper part is a top seat 2, and the interior is a furnace cavity 39; Vacuum pump 6, water tank 8; Vacuum tube 7 is provided on the top of va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com