Production technology of transparent iron oxide

A transparent iron oxide, production process technology, applied in the directions of iron oxide, iron oxide/iron hydroxide, nanotechnology, etc., can solve the problems of impure hue, difficult to control the particle size and shape of iron oxide red, poor dispersibility, etc. Pure, good dispersion, not easy to agglomerate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

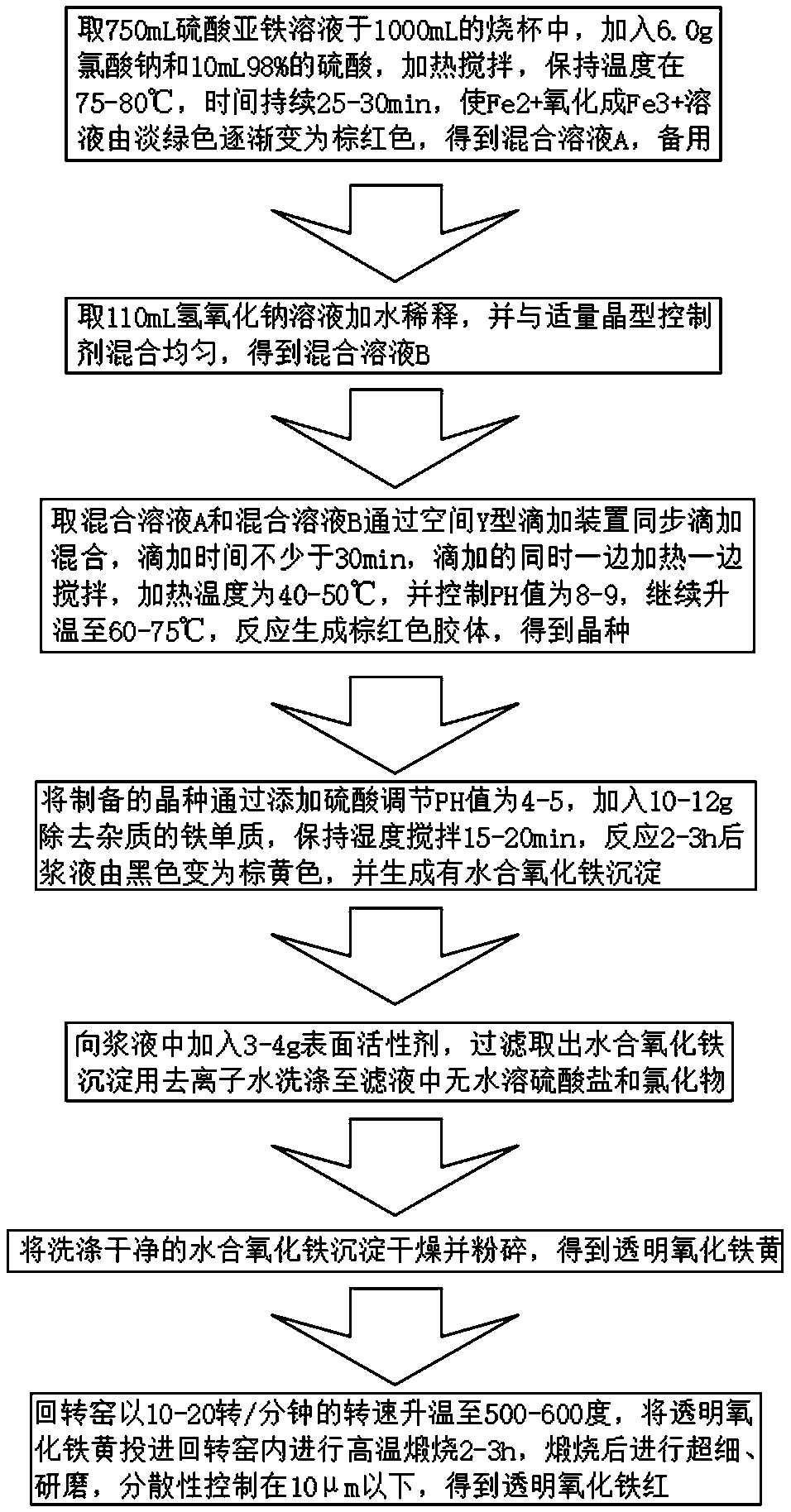

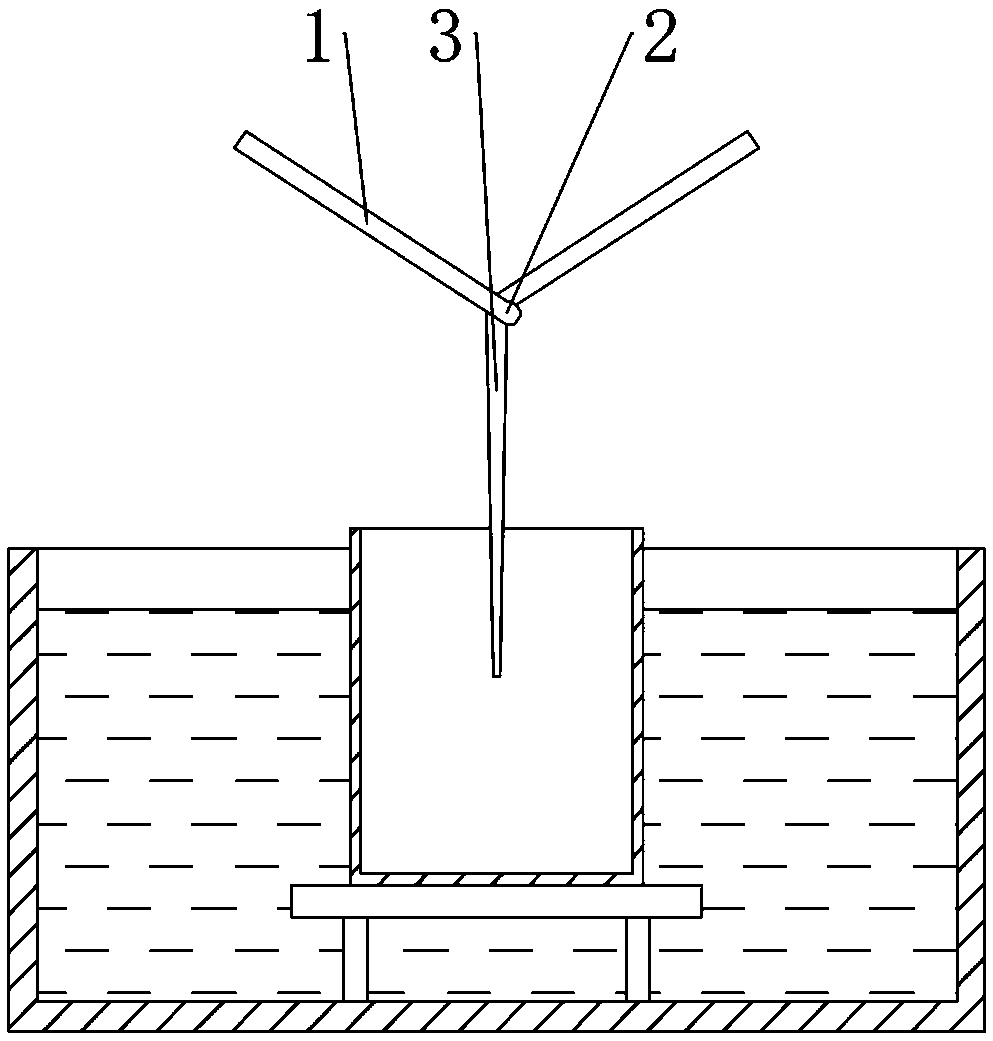

[0048] see figure 1 , take 750mL of ferrous sulfate solution in a 1000mL beaker, add 6.0g of sodium chlorate and 10mL of 98% sulfuric acid, heat and stir, keep the temperature at 80°C for 25min, so that Fe 2+ Oxidized to Fe 3+ The solution gradually changed from light green to brownish red, and mixed solution A was obtained, which was set aside; take 110mL sodium hydroxide solution and dilute it with water, the mass fraction of sodium hydroxide solution is 30%, and mix it with an appropriate amount of crystal form control agent evenly to control the crystal form. Sodium hexametaphosphate is selected as the agent, its function is to control the size and uniformity of the hydrated iron oxide yellow particles α-FeOOH, and avoid the formation of γ-FeOOH mixed crystals when the α-FeOOH particles are formed. If the iron oxide yellow contains γ-FeOOH mixed crystals , the iron oxide yellow powder will have a reddish-dark hue, uneven particle size, and inconsistent particle shape, and...

Embodiment 2

[0051] see figure 1 , take 750mL of ferrous sulfate solution in a 1000mL beaker, add 6.0g of sodium chlorate and 10mL of 98% sulfuric acid, heat and stir, keep the temperature at 75°C for 30min, so that Fe 2+ Oxidized to Fe 3+ The solution gradually changed from light green to brownish red, and mixed solution A was obtained, which was set aside; take 110mL sodium hydroxide solution and dilute it with water, the mass fraction of sodium hydroxide solution is 30%, and mix it with an appropriate amount of crystal form control agent evenly to control the crystal form. Sodium hexametaphosphate was selected as the agent to obtain mixed solution B; mixed solution A and mixed solution B were mixed dropwise and mixed synchronously through a space Y-shaped dropping device, and the dropping time was 35min, while heating while stirring, the heating temperature was 45°C, and control the pH value to 8, continue to heat up to 70°C, the reaction will form a brown-red colloid, that is, FeOH 3...

Embodiment 3

[0053] see figure 1 , take 750mL of ferrous sulfate solution in a 1000mL beaker, add 6.0g of sodium chlorate and 10mL of 98% sulfuric acid, heat and stir, keep the temperature at 80°C for 30min, so that Fe 2+ Oxidized to Fe 3+ The solution gradually changed from light green to brownish red, and mixed solution A was obtained, which was set aside; take 110mL sodium hydroxide solution and dilute it with water, the mass fraction of sodium hydroxide solution is 30%, and mix it with an appropriate amount of crystal form control agent evenly to control the crystal form. Sodium hexametaphosphate was selected as the agent to obtain mixed solution B; mixed solution A and mixed solution B were added dropwise and mixed synchronously through a space Y-shaped dropping device, and the dropping time was not less than 40 minutes. The temperature is 50°C, and the pH value is controlled to be 9, and the temperature continues to rise to 75°C, and the reaction produces a brown-red colloid, namely...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com