Plant-based oil absorption pillow and preparation method thereof

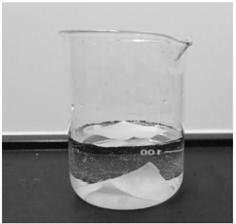

An oil-absorbing pillow and plant-based technology, applied in separation methods, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of secondary pollution, poor oil retention capacity of plant fibers, etc., and achieve fast oil absorption speed and oil-water selection Strong and easy to transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of plant-based oil-absorbing pillow, comprising the following steps:

[0044] The hydrophobic modified cotton fabric is sewn into a pillow shell, filled with plant fibers, and sealed to form a plant-based oil-absorbing pillow.

[0045] Wherein, the hydrophobically modified cotton fabric is made by the following steps:

[0046] Spray the cotton fabric with plant polyphenol solution and metal ion solution in turn, then wash and dry to complete the surface modification of cotton fabric once;

[0047] The surface modification of cotton fabrics was carried out several times to obtain cotton fabrics modified by metal ion complexes-plant polyphenols;

[0048] The metal ion complex-plant polyphenol modified cotton fabric is immersed in the low surface energy compound solution for reaction, and then the cotton fabric is taken out and dried to obtain the hydrophobically modified cotton fabric.

[0049] In the embodiment o...

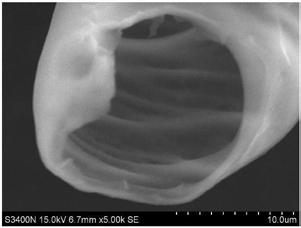

Embodiment 1

[0057] Cut a piece of clean cotton cloth (5cm×5cm), spray both sides with 3.4mg / mL tannic acid aqueous solution (pH value 7.0), let it stand for 20S; then use 5mg / mL copper sulfate The aqueous solution was sprayed on both sides of the cotton cloth in turn, and left to stand for 60 seconds; the cotton cloth was washed three times with deionized water and absolute ethanol, and then dried. The steps of spraying, washing and drying were repeated 5 times to obtain copper ion complex-tannic acid modified cotton cloth.

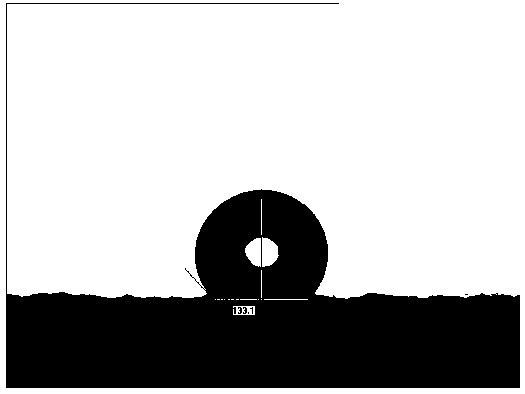

[0058] Immerse the prepared copper ion complex-tannic acid modified cotton cloth in 20mL of ethanol solution containing octadecylamine (concentration is 4.0mg / mL), adjust the pH value of the mixed solution to 8.5 with triethylamine, at 25 Under the condition of ℃, the magnetic stirring reaction is carried out for 8h (100-500rpm / min), the cotton cloth after reaction is taken out, and dried in a vacuum oven at 80°C to obtain the hydrophobic modified cotton cloth. The ...

Embodiment 2

[0063] Cut a piece of clean cotton cloth (5cm×5cm), spray both sides with 10.2mg / mL tannic acid aqueous solution (pH value 9.0), let stand for 20S; then use 10mg / mL copper sulfate The aqueous solution was sprayed on both sides of the cotton cloth in turn, and left to stand for 20 seconds; the cotton cloth was washed three times with deionized water and absolute ethanol, and then dried. The steps of spraying, washing and drying were repeated 10 times to obtain copper ion complex-tannic acid modified cotton cloth.

[0064] Immerse the prepared copper ion complex-tannic acid modified cotton cloth in 20mL of ethanol solution containing octadecylamine (8.0mg / mL), adjust the pH value of the mixed solution to 8.5 with triethylamine, at 30°C , and magnetically stirred for 4 hours (100-500 rpm / min), the cotton cloth after reaction was taken out, and dried in a vacuum oven at 80° C. to obtain a hydrophobic modified cotton cloth. The measured static contact angle between deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com