Microcapsule composite wall material, and microcapsule essence, preparation method and applications thereof

A microcapsule essence and microcapsule technology, which is applied in the direction of microcapsule preparation, preparation of microspheres, washing composition fragrances, etc., can solve the shortage of multifunctional moisturizing, anti-wrinkle, sunscreen, anti-itch skin care products, and the essence is easily destroyed. problem, achieve the effect of enhancing the fragrance retention effect, lasting fragrance time and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A microcapsule composite wall material, comprising xanthan gum, chitosan oligosaccharide and deionized water, wherein the content of xanthan gum is 2-5 parts, the content of chitosan oligosaccharide is 0.5-1.5 parts, and the content of deionized water is 55-5 parts 60 servings.

[0044] The microcapsule composite wall material also includes a preservative, and the preservative is DMDM hydantoin with a content of 0.05-0.15 parts.

[0045] The preparation method of the microcapsule composite wall material comprises the following steps:

[0046] S1. Add xanthan gum and chitosan oligosaccharide into deionized water at 70-80°C and stir rapidly for 0.5 hours until completely dissolved to obtain a solution;

[0047] S2. Vacuumize to remove the air bubbles in the solution, then lower the temperature to 35°C, then add the preservative, and continue to stir until completely dissolved.

Embodiment 2

[0049] A microcapsule flavor wrapped by a microcapsule composite wall material, comprising phase A, phase B and phase C, wherein,

[0050] Phase A includes 2 to 5 parts of xanthan gum, 0.5 to 1.5 parts of chitosan oligosaccharide, and 55 to 60 parts of deionized water;

[0051] Phase B includes 30-35 parts of essence and 6-7 parts of solubilizer;

[0052] Phase C includes preservatives.

[0053] Xanthan gum, chitosan oligosaccharides, deionized water, and preservatives form a functional microcapsule wall material as a protective outer layer, and the inner layer is composed of a solubilizer and essence. Through the addition of chitosan oligosaccharides, on the one hand, it forms a protective wall membrane of essence, on the other hand, it has obvious moisturizing effect, and at the same time, it can activate body cells, prevent skin roughness and aging, inhibit the growth of harmful bacteria on the skin surface, inhibit bacteria and resist skin diseases and UV absorption func...

Embodiment 3

[0064] Microencapsulated fragrance applications can be added to shampoo, body wash or laundry detergent products.

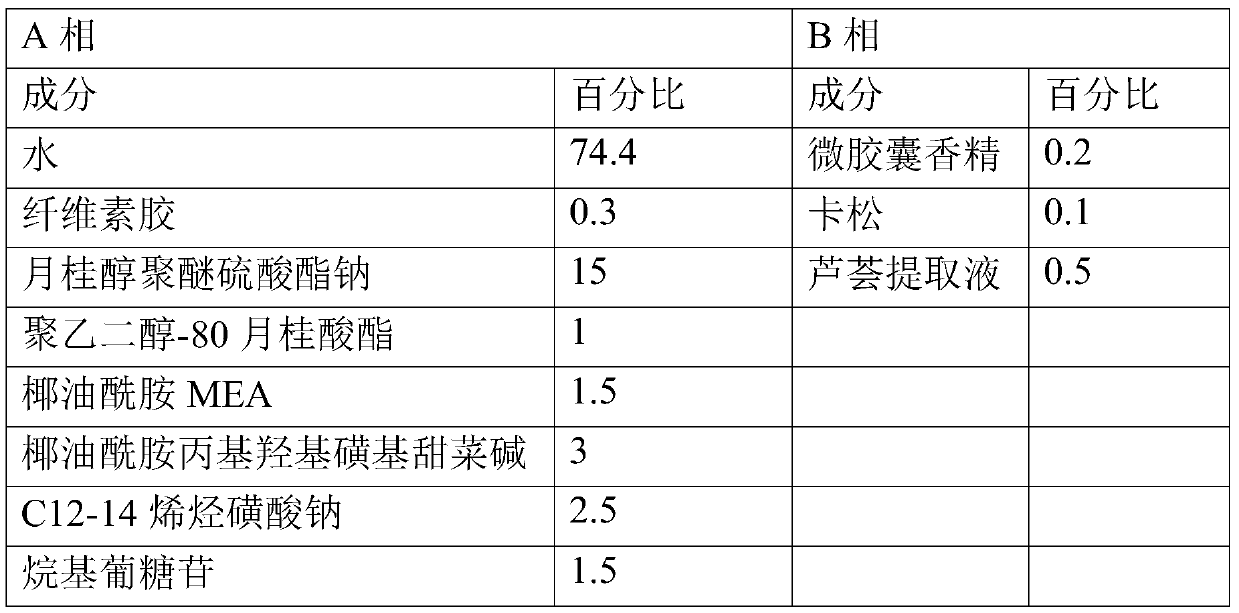

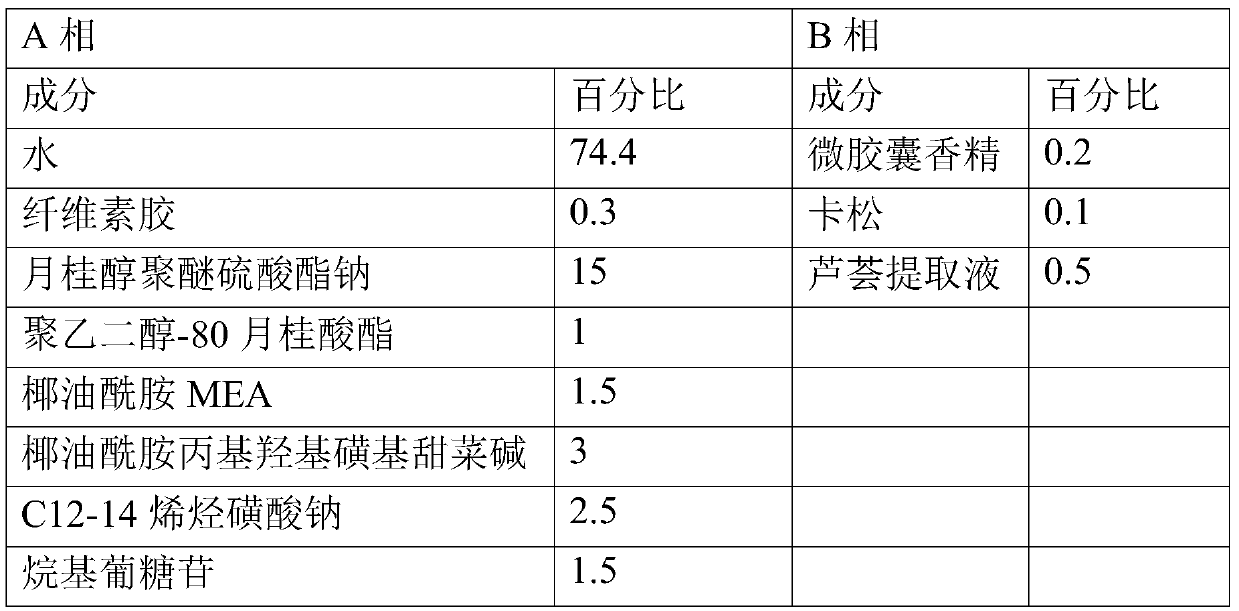

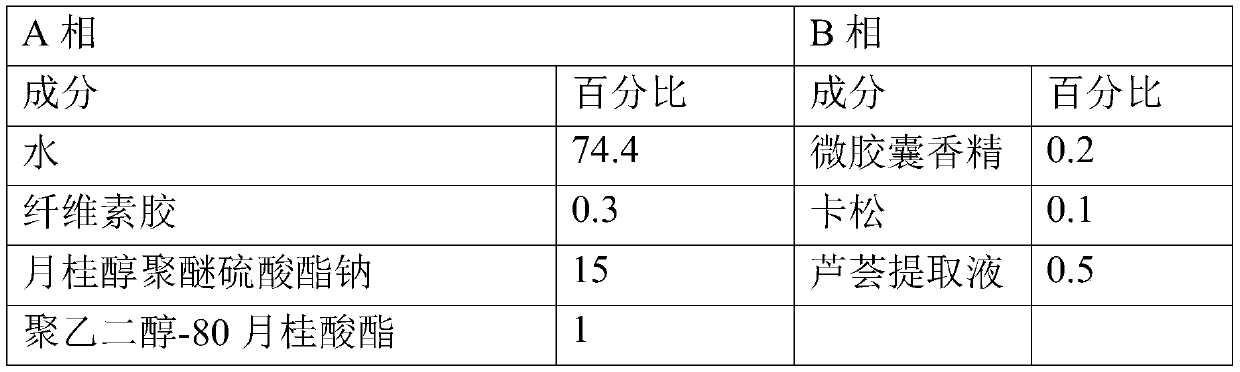

[0065] The composition and content of the laundry detergent product of the present embodiment are as follows:

[0066]

[0067]

[0068] When preparing,

[0069] 1. Clean the relevant equipment and utensils;

[0070] 2. Stir the components of Phase A and heat up to 80-85°C until dissolved, then cool down. When the temperature drops to 45°C, add the components of Phase B in turn and stir well.

[0071] 3. Semi-finished product inspection and discharge.

[0072] 4. Filling, finished product inspection, storage.

[0073] Adding microcapsule essence to laundry detergent to form the outer layer of essence wall material can avoid the oxidative deterioration of fragrance substances directly affected by heat and light, avoid the volatilization of active ingredients, effectively control the release of fragrance substances, and improve the stability of fragrance. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com