Sodium azide synthesis process

A sodium azide and synthesis process technology, applied in the direction of azide acid/azide/halogen azide, etc., can solve the problems of safety hazards, large liquid holding capacity, environmental pollution, etc., and achieve low risk and side effects The effect of low product and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

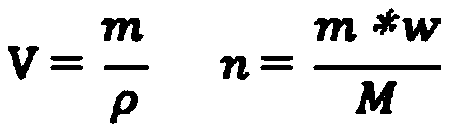

[0019] Connect the G1 microchannel reactor module (a complete set of 10 modules, with a total liquid holding capacity of 90ml), rinse the pipeline with methanol, and use a high-pressure liquid phase pump to prepare a molar ratio of n (水合肼) :n (氢氧化钠) :n (水) = 1:1:2 water phase mixture and molar ratio is n (亚硝酸甲酯) :n (甲醇) = 1:1 oil phase mixture, put into 10 G1 reactor modules, the design flux is 30ml / min, combined with the measured water phase density and oil phase density, calculate the mass flow rate of the two phases as m (水相) =17.3g / min, m (油相) =12.86g / min, respectively use a stopwatch and an electronic scale to calibrate the two-phase mass flow. After the normal feed rate is calibrated, adjust the back pressure to 2bar, raise the temperature to 50°C, and react for 15 minutes to sample, quench and separate. The aqueous phase is the sodium azide aqueous solution. Take out the sample and use potentiometric titration to determine the aqueous phase According to the content...

Embodiment 2

[0032] Connect the G1 microchannel reactor module (a complete set of 10 modules, with a total liquid holding capacity of about 90ml), rinse the pipeline with ethanol, and use a high-pressure liquid phase pump to prepare a molar ratio of n (水合肼) :n (氢氧化钠) :n (水溶液) = 1:1:2 water phase mixture and molar ratio is n (亚硝酸乙酯) :n (乙醇) = 1:1 oil phase mixture, put into 10 G1 reactor modules, the design flux is 30ml / min, combined with the measured water phase density and oil phase density, calculate the mass flow rate of the two phases as m (水相) =18.5g / min, m (油相) =11.9g / min, respectively use a stopwatch and an electronic scale to calibrate the two-phase mass flow. After the normal feed rate is calibrated, adjust the back pressure to 2bar, raise the temperature to 50°C, and react for 15 minutes to sample, quench and separate. The aqueous phase is the sodium azide aqueous solution. Take out the sample and use potentiometric titration to determine the aqueous phase According to the c...

Embodiment 3

[0034] Connect the G1 microchannel reactor module (a complete set of 10 modules, with a total liquid holding capacity of about 90ml), rinse the pipeline with isopropanol, and use a high-pressure liquid phase pump to prepare a molar ratio of n (水合肼) :n (氢氧化钠) :n (水溶液) = 1:1.3:2 water phase mixture and molar ratio is n (亚硝酸异丙酯) :n (异丙醇) = 1:1 oil phase mixture, put into 10 G1 reactor modules, the design flux is 50ml / min, combined with the measured water phase density and oil phase density, calculate the mass flow rate of the two phases as m (水相) =28.6g / min, m (油相) =21.43g / min, respectively use a stopwatch and an electronic scale to calibrate the two-phase mass flow. After the normal feed rate is calibrated, adjust the back pressure to 2bar, raise the temperature to 50°C, and react for 9 minutes to sample, quench and separate. The aqueous phase is the sodium azide aqueous solution. Take out the sample and use potentiometric titration to determine the aqueous phase. According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com