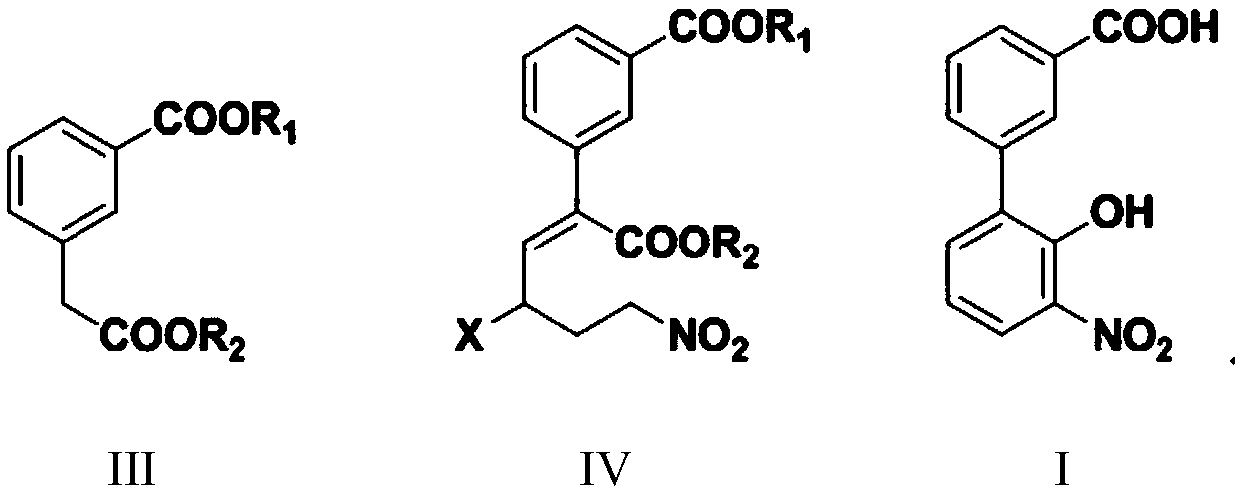

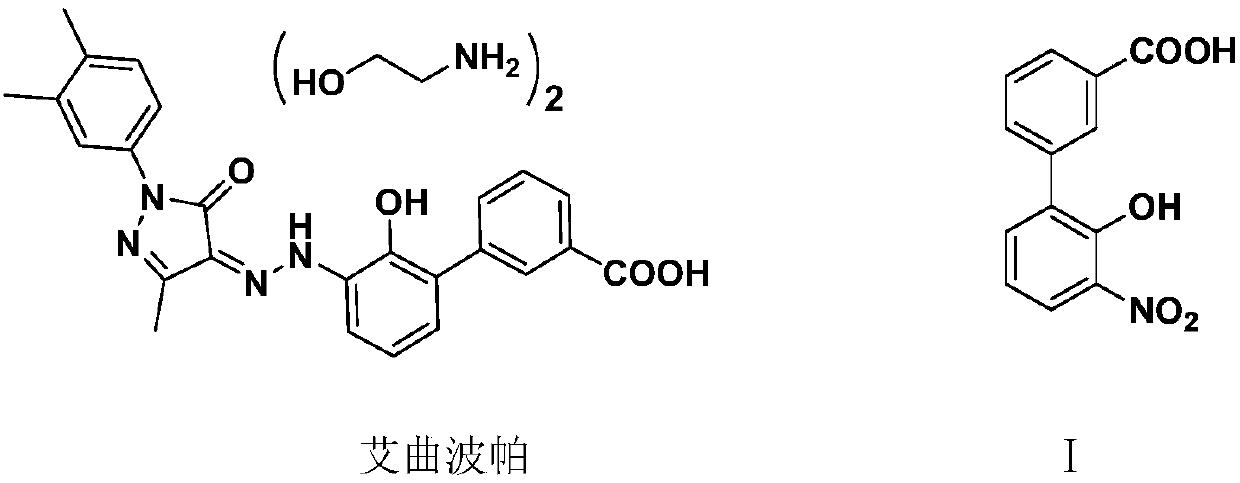

Preparation method of 3'-nitro-2'-hydroxybiphenyl-3-formic acid

A technology of hydroxybiphenyl and nitromethane, applied in the field of medicinal chemistry, can solve the problems of increasing the reaction cost and being unsuitable for large-scale production, and achieves the effects of low cost, high selectivity, and low production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

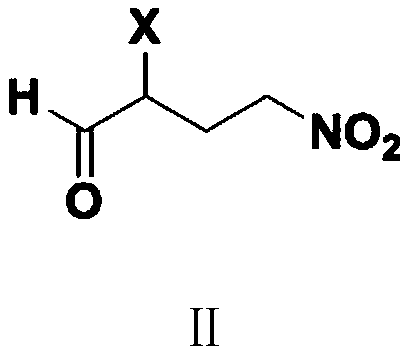

[0052] Embodiment 1: the preparation of 2-chloro-4-nitro n-butyraldehyde (Ⅱ1)

[0053] Add 30.0 g of THF, 9.0 g (0.1 mole) of 2-chloroacrolein, 6.2 g (0.1 mole) of nitromethane, and 0.1 g of DBU into a 500 ml four-necked flask connected with a stirring and thermometer, and stir at 45 to 50 °C React for 5 hours. After the solvent was recovered by distillation, the (80-100°C / 1-2mmHg) fraction was collected by vacuum distillation to obtain 13.9 g of 2-chloro-4-nitro-n-butyraldehyde (II1), with a yield of 91.8% and a gas phase purity of 99.7%.

Embodiment 2

[0054] Embodiment 2: the preparation of 2-chloro-4-nitro n-butyraldehyde (Ⅱ1)

[0055] Add 90.0 g (1.0 mol) of 2-chloroacrolein, 64.0 g (1.0 mol) of nitromethane, and 1.0 g of DBU into a 500 ml four-neck flask connected with a stirring and thermometer, and stir at 60 to 65° C. for 5 hours. Fractions (80-100°C / 1-2mmHg) were collected by distillation under reduced pressure to obtain 149.3 g of 2-chloro-4-nitro-n-butyraldehyde (II1), with a yield of 98.6% and a gas phase purity of 99.6%.

Embodiment 3

[0056] Embodiment 3: the preparation of 2-bromo-4-nitro n-butyraldehyde (Ⅱ2)

[0057] Add 30.0 g of acetonitrile, 13.5 g (0.1 mole) of 2-bromoacrolein, 6.2 g (0.1 mole) of nitromethane, and 0.1 g of DBU into a 500 ml four-neck flask connected with a stirring and thermometer, and stir at 55 to 60 ° C React for 3 hours. After recovering the solvent by distillation, the (95-115°C / 1-2mmHg) fraction was collected by vacuum distillation to obtain 17.6 g of 2-bromo-4-nitro-n-butyraldehyde (II2), with a yield of 89.8% and a gas phase purity of 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com