A kind of method for preparing m-xylylene diisocyanate

A technology of m-xylylene diisocyanate and m-xylylene diurethane, which is applied in the field of compound preparation, can solve the problem of low yield of 1,6-hexamethylene diisocyanate, high price of ionic liquid, The product yield is not high, and the effect of easy industrialization and automation, low cost and easy separation is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-29

[0037] The present embodiment prepares m-xylylene diisocyanate, and its preparation method comprises the steps:

[0038] Adopt 1000mL reactor as thermal decomposition reactor, and x g ethyl m-xylylene dicarbamate, yg solvent A, z g catalyst B are added to reactor, seal reactor, start stirring, control pressure is a MPa, temperature is b°C, and a thermal decomposition reaction is carried out under cmL / min nitrogen purging for t min to obtain the m-xylylene diisocyanate.

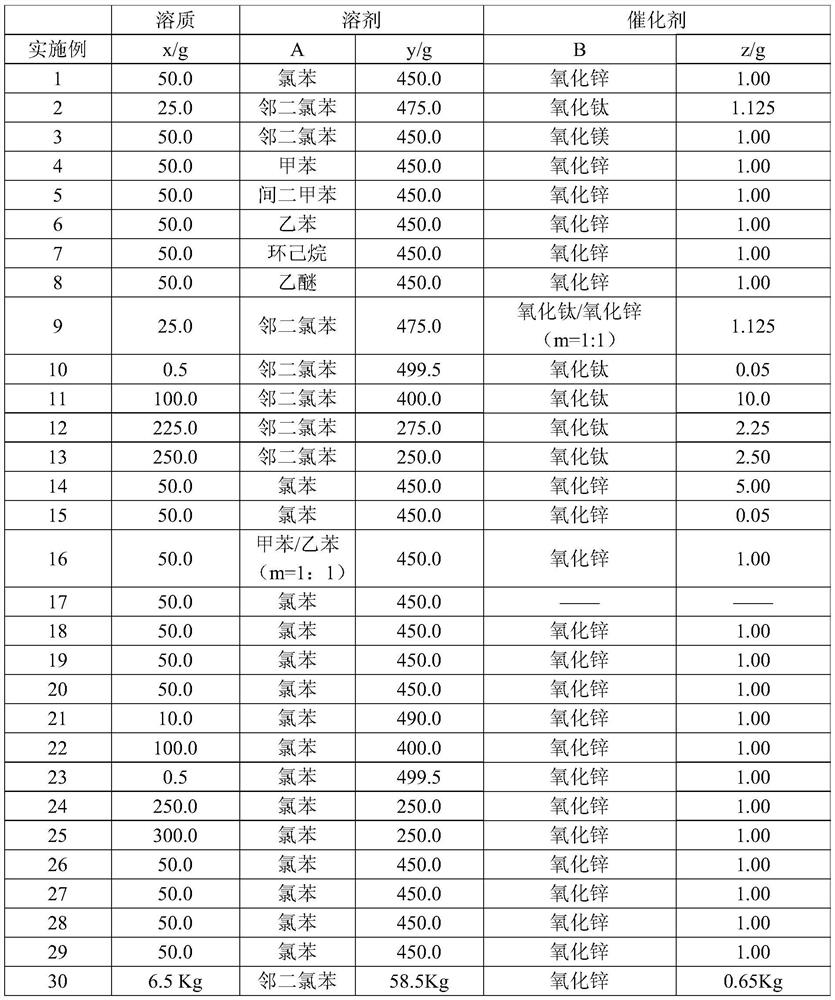

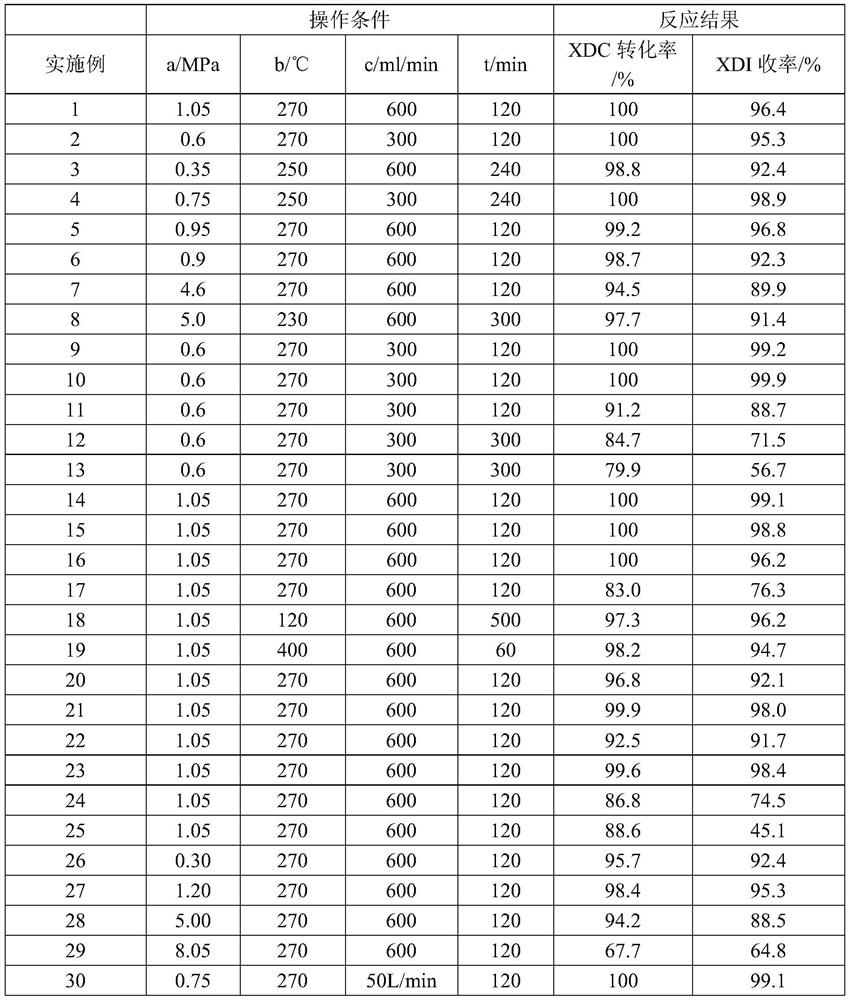

[0039] In the preparation method of embodiment 1-29, the concrete numerical value of each parameter and the conversion ratio of raw material xylylene diurethane (XDC), the yield of m-xylylene diisocyanate (XDI) are as table 1 and Table 2 shows.

Embodiment 30

[0041] The present embodiment carries out enlarged preparation m-xylylene diisocyanate, and its preparation method comprises the following steps:

[0042] A 100L reactor was used as a thermal decomposition reactor, and 6.5Kg of ethyl m-xylylenedicarbamate, 58.5Kg of o-dichlorobenzene, and 0.65Kg of zinc oxide were added to the reactor, and the reactor was sealed, stirred, and the pressure was controlled. The temperature is 0.75MPa, the temperature is 270°C, and the thermal decomposition reaction is carried out under 50L / min nitrogen purging for 120min to obtain the m-xylylene diisocyanate.

[0043] The yield of m-xylylene diisocyanate (XDI) prepared in Examples 1-30 and the conversion rate of the raw material m-xylylene diurethane (XDB) are shown in Table 1 and Table 2.

[0044] Table 1

[0045]

[0046] Table 2

[0047]

[0048] According to the data of Table 1 and Table 2, it can be known that: comparative example 1 and embodiment 21-25, the mass percent concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com