Covalent organic framework material catalyst based on loaded Ru nanoparticles as well as preparation method and application of the catalyst

A covalent organic framework and nanoparticle technology, which is applied in the field of electrocatalysis, can solve the problems of the catalytic activity of the catalyst to be improved, and achieve the effects of good recycling stability, optimized electronic structure, and small particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Thoroughly grind and mix 0.64g of terephthalonitrile, 0.64g of 2,6-pyridinedicarbonitrile and 3.2g of conductive carbon black powder in a mortar to obtain mixture A. Place 6.4g of anhydrous zinc chloride, the above-mentioned mixture A and 6.4g of anhydrous zinc chloride in the crucible from bottom to top (that is, mixture A is placed between two layers of anhydrous zinc chloride powder);

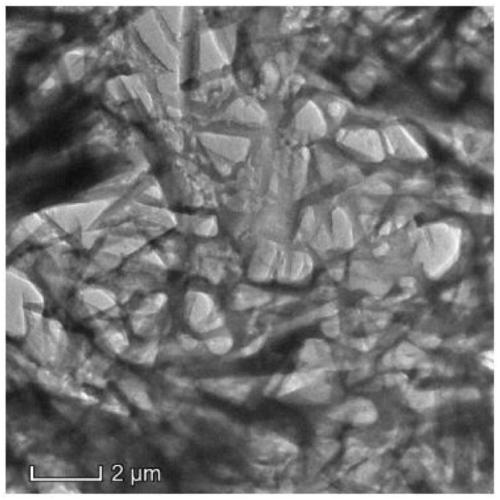

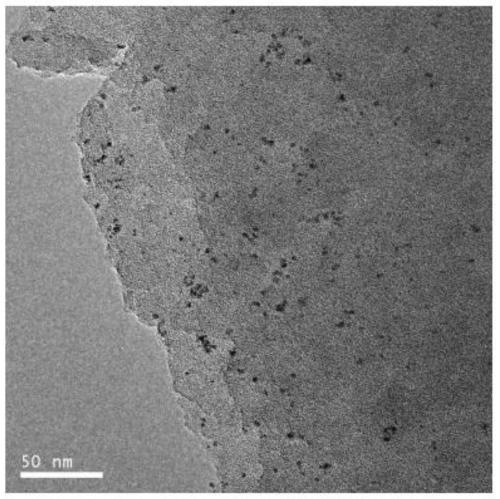

[0029] 2) Place the crucible in step 1) in a tube furnace, and perform high-temperature calcination under the protection of nitrogen. The calcination temperature is 400°C, the calcination time is 40 hours, and the nitrogen flow rate into the tube furnace is 50 mL / min. The calcined product was successively stirred and washed with 1 mol / L hydrochloric acid solution and deionized water for 12 hours, and the washed solid was vacuum-dried at 60°C for 12 hours to obtain the covalent organic framework carrier powder (Step 2 of Example 1) The prepared covalent organic framework carrier pow...

Embodiment 2

[0042] 1) Thoroughly grind and mix 0.64g of terephthalonitrile, 0.64g of 2,6-pyridinedicarbonitrile and 3.2g of conductive carbon black powder in a mortar to obtain mixture A. Place 6.4g of anhydrous zinc chloride, the above-mentioned mixture A and 6.4g of anhydrous zinc chloride in the crucible from bottom to top (that is, mixture A is placed between two layers of anhydrous zinc chloride powder);

[0043] 2) Place the crucible in step 1) in a tube furnace, and perform high-temperature calcination under the protection of nitrogen. The calcination temperature is 400°C, the calcination time is 40 hours, and the nitrogen flow rate into the tube furnace is 50 mL / min. The calcined product was successively stirred and washed with 1 mol / L hydrochloric acid solution and deionized water for 12 hours, and the washed solid was vacuum-dried at 60°C for 12 hours to obtain the covalent organic framework carrier powder;

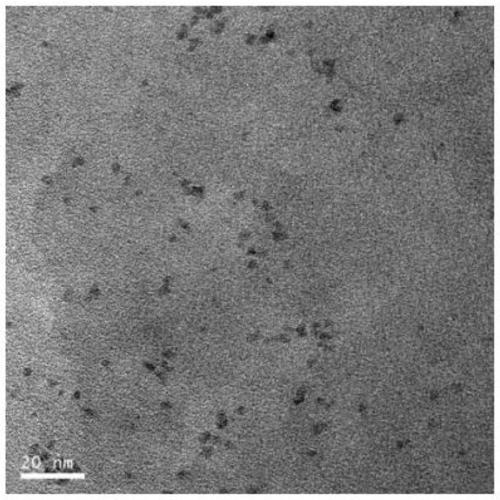

[0044] 3) Put 50 mg of the covalent organic framework carrier powder o...

Embodiment 3

[0049] Take 50 mg of conductive carbon black powder and 20.8 mg of ruthenium acetylacetonate and place them in a mortar and grind them thoroughly until they are evenly mixed, then perform high-temperature calcination in a tube furnace under nitrogen protection, and heat up from room temperature at 3 °C / min to 300 °C, and Calcined at 300° C. for 3 hours, and the calcined product was washed with ultrapure water and dried to obtain the target catalyst.

[0050] The electrocatalytic ammonia synthesis performance test of the catalyst that embodiment 3 obtains is as follows:

[0051] Weigh 4.0 mg of the catalyst of Example 3, add 900 microliters of ethanol and 100 microliters of Nafion solution (the mass fraction of Nafion solution is 5%), and sonicate for 0.5 hours until the catalyst is completely dispersed to obtain a uniform catalyst slurry. Pipette 0.2 mL of the catalyst slurry prepared above and spread it evenly on a 1 cm × 1 cm carbon paper, dry it, and use it as a working ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com