Environment-friendly plate deodorant and preparation method thereof

A deodorant and environment-friendly technology, applied in the field of environment-friendly plate deodorizer and its preparation, can solve the problems of odor and harmful substances not being completely removed, affecting wood quality, and surface corrosion of plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

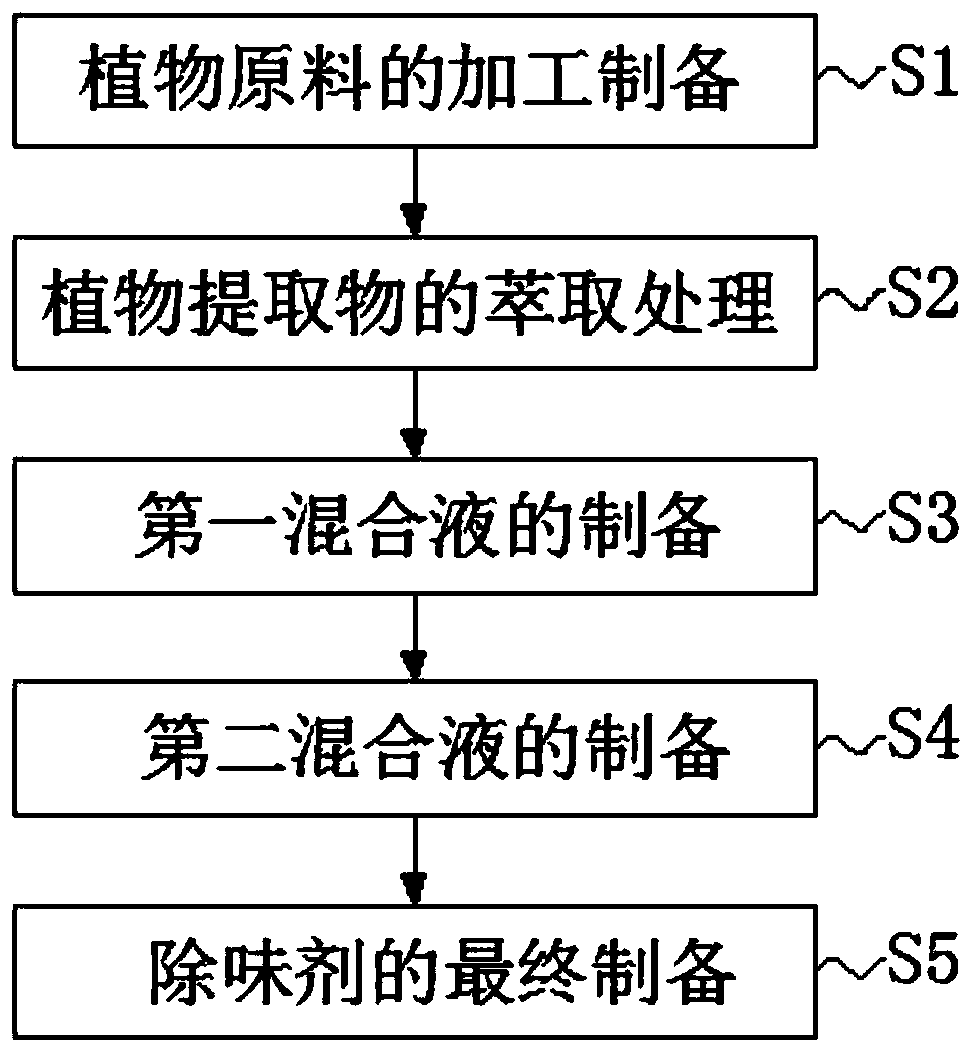

Method used

Image

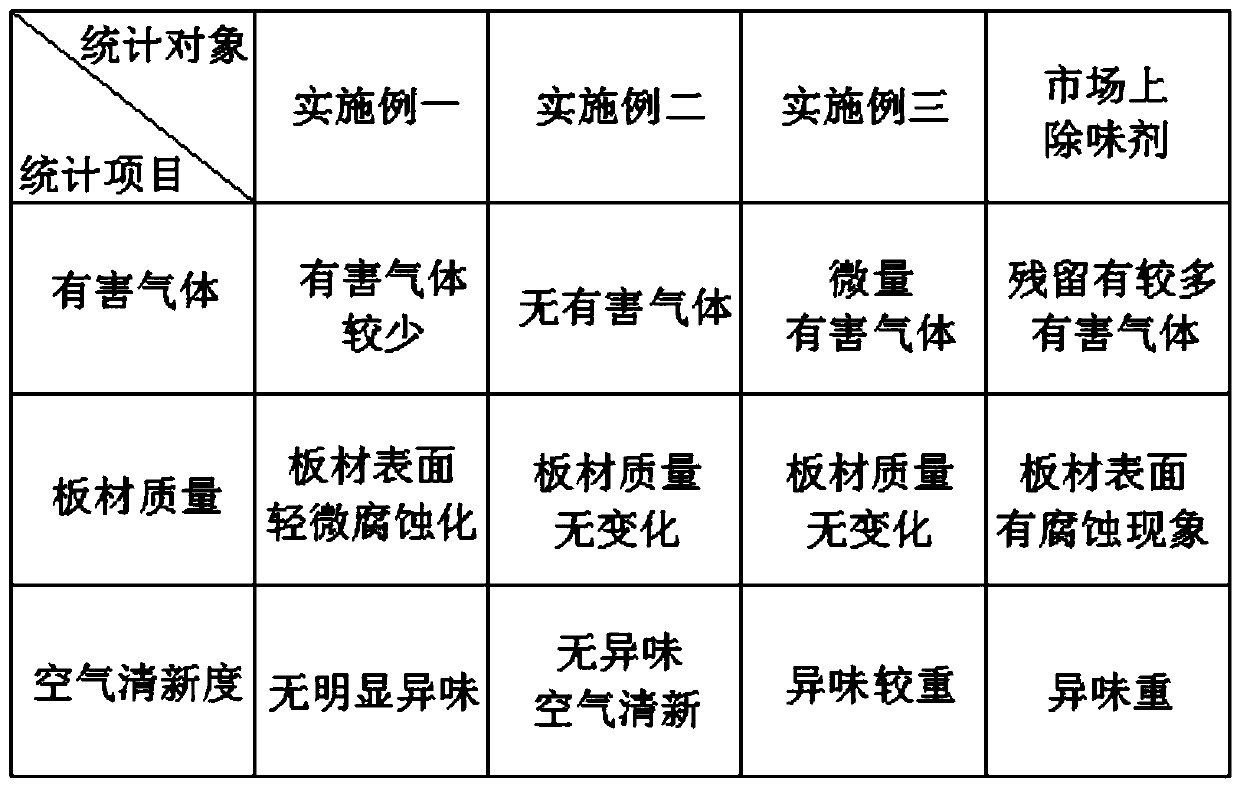

Examples

Embodiment 1

[0027]S1. Processing and preparation of plant raw materials: put 12 parts of plant extracts into a high-speed pulverizer for pulverization, set the pulverization time to 30 minutes, after pulverization is even, put it into an extraction kettle for supercritical extraction, and set the extraction temperature The temperature is 40°C, and the extraction time is 80 minutes. After the extraction is completed, the extracted product is obtained. After the extraction is completed, it is centrifuged at a speed of 6000r / min. After 20 minutes, the precipitated impurities at the bottom are removed to obtain plant raw materials;

[0028] S2. Extraction treatment of plant extracts: Add 10 parts of absolute ethanol and 5 parts of stabilizer to the filtered plant material in S1, put it into a mixer at a speed of 300r / min for extraction, and pass it through 200 meshes after 1h Filter through a sieve to finally obtain the plant extract;

[0029] S3. Preparation of the first mixed solution: put ...

Embodiment 2

[0033] S1. Processing and preparation of plant raw materials: put 13 parts of plant extracts into a high-speed pulverizer for pulverization, and set the pulverization time to 40 minutes. After pulverization is uniform, put it into an extraction kettle for supercritical extraction, and set the extraction temperature The temperature is 50°C, and the extraction time is 90 minutes. After the extraction is completed, the extracted product is obtained. After the extraction is completed, the centrifugal separation is carried out at a speed of 7000r / min. After 30 minutes, the precipitated impurities at the bottom are removed to obtain the plant raw material;

[0034] S2. Extraction treatment of plant extracts: Add 11 parts of absolute ethanol and 6 parts of stabilizer to the filtered plant material in S1, put it into a mixer at a speed of 300r / min for extraction, and pass it through 200 meshes after 2 hours Filter through a sieve to finally obtain the plant extract;

[0035] S3. Prepa...

Embodiment 3

[0039] S1. Processing and preparation of plant raw materials: put 14 parts of plant extracts into a high-speed pulverizer for pulverization, and set the pulverization time to 50 minutes. The temperature is 60°C, and the extraction time is 100 minutes. After the extraction is completed, the extracted product is obtained. After the extraction is completed, the centrifugal separation is performed at a speed of 8000r / min. After 40 minutes, the precipitated impurities at the bottom are removed to obtain plant raw materials;

[0040] S2. Extraction treatment of plant extracts: Add 12 parts of absolute ethanol and 7 parts of stabilizer to the filtered plant material in S1, put it into a mixer at a speed of 300r / min for extraction, and pass through 200 meshes after 3 hours Filter through a sieve to finally obtain the plant extract;

[0041] S3, preparation of the first mixed solution: put 22 parts of nano-carbon powder, 15 parts of sodium chloride, 8 parts of dispersant, 12 parts of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com