Preparation process of waterproof fiber gypsum board

A preparation process and technology of gypsum board, which is applied in the field of decorative materials, can solve the problems that fiber gypsum board does not have waterproofness, etc., and achieve the effects of excellent waterproof and moisture resistance, improved mechanical strength, and improved waterproof and moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

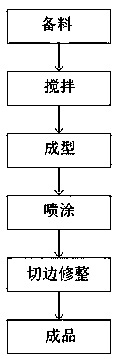

[0032] A preparation process for waterproof fiber gypsum board, comprising the following steps:

[0033] (1) Preparation of materials:

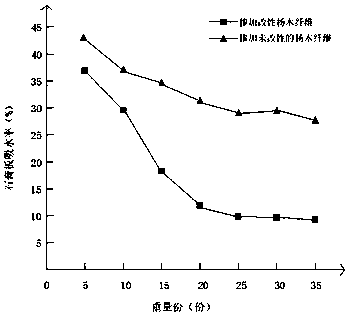

[0034] (1) In parts by weight: Weigh 20 parts of modified starch, 18 parts of modified poplar fiber, 2 parts of sodium citrate, 0.6 parts of calcium lignosulfonate and 20-30 parts of water and put them into a hydropulper Stir in the middle to form a raw material slurry, and then pump the raw material slurry into the slurry storage tank for standby;

[0035] Wherein the preparation process of modified poplar fiber is:

[0036] ① First add 50 parts of water to the reaction kettle, add 0.6 parts of alkylphenol polyoxyethylene ether into the container under stirring conditions and emulsify, then heat the emulsified mixture to 60°C, and then add 10 parts Stearic acid is stirred until completely melted, then 10 parts of calcium hydroxide powder is added to the mixed solution containing stearic acid, stirred for 2 minutes, and then incubated for 2...

Embodiment 2

[0048] A preparation process for waterproof fiber gypsum board, comprising the following steps:

[0049] (1) Preparation of materials:

[0050] (1) In parts by weight: Weigh 27 parts of modified starch, 20 parts of modified poplar fiber, 4 parts of sodium carboxymethyl cellulose, 0.9 parts of sodium sulfamate and 25 parts of water and put them into a hydropulper Stir in the middle to form a raw material slurry, and then pump the raw material slurry into the slurry storage tank for standby;

[0051] Wherein the preparation process of modified poplar fiber is:

[0052] ① First add 70 parts of water to the reaction kettle, add 0.8 parts of alkylphenol polyoxyethylene ether into the container under stirring conditions and emulsify, then heat the emulsified mixture to 65 ° C, then add 12 parts Stearic acid is stirred until completely melted, then 11 parts of calcium hydroxide powder are added to the mixed solution containing stearic acid, stirred for 4 minutes and then kept for 2...

Embodiment 3

[0064] A preparation process for waterproof fiber gypsum board, comprising the following steps:

[0065] (1) Preparation of materials:

[0066] (1) In parts by weight: Weigh 35 parts of modified starch, 22 parts of modified poplar fiber, 5 parts of sodium carboxymethyl cellulose, 1.4 parts of sodium polyacrylate and 30 parts of water and put them into a hydropulper Stir into raw material slurry, then pump the raw material slurry into the slurry storage tank for standby;

[0067] Wherein the preparation process of modified poplar fiber is:

[0068] ① First add 100 parts of water to the reaction kettle, add 1.2 parts of alkylphenol polyoxyethylene ether into the container under stirring conditions and emulsify, then heat the emulsified mixture to 70°C, then add 15 parts Stearic acid is stirred until completely melted, then 12 parts of calcium hydroxide powder are added to the mixed solution containing stearic acid, stirred for 5 minutes, and then incubated for 30 minutes to ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com