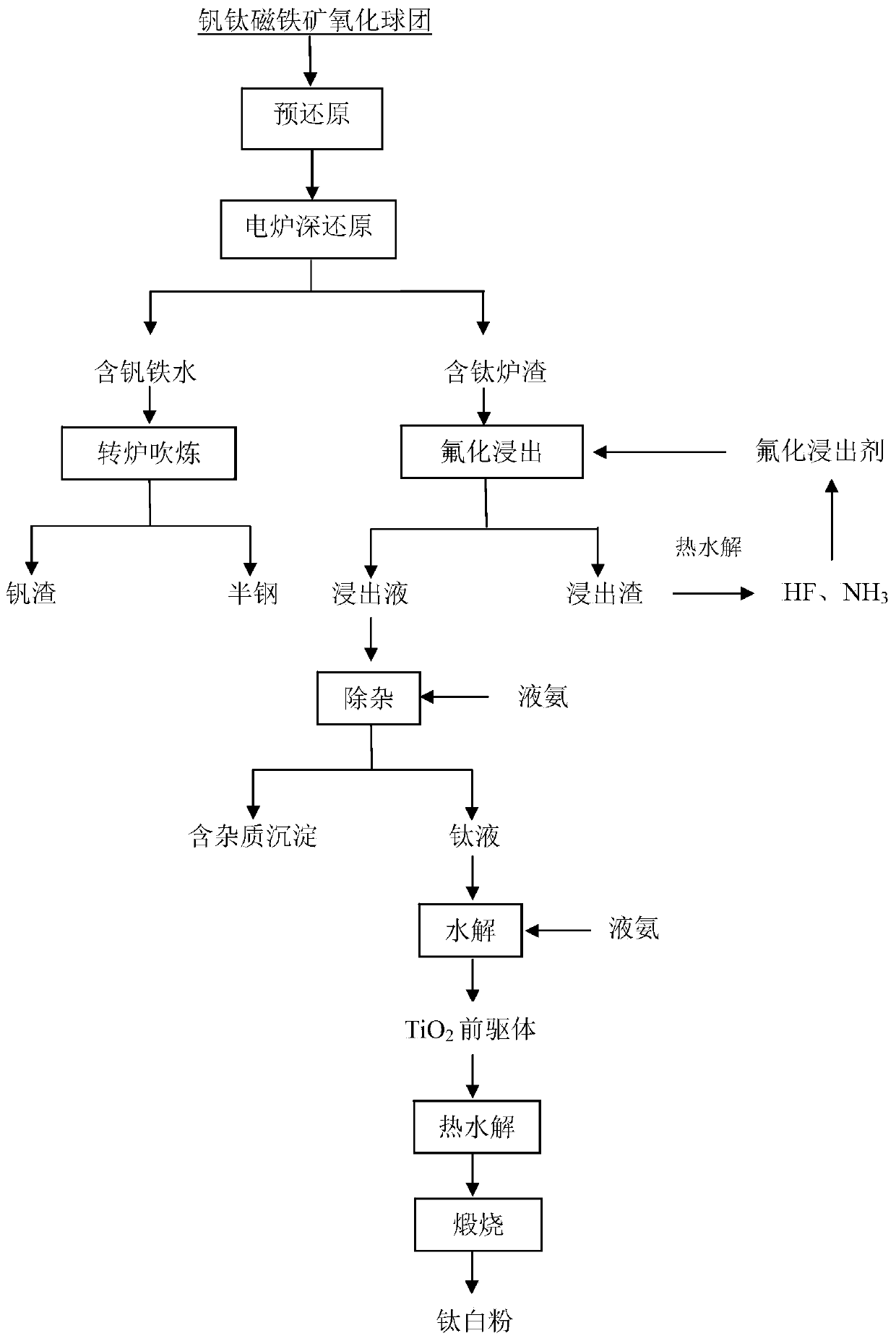

Process for comprehensively utilizing vanadium titano-magnetite via prereduction-electric furnace deep reduction-fluorination method

A vanadium-titanium magnetite and vanadium-titanium magnet technology, applied in the direction of titanium dioxide, process efficiency improvement, titanium oxide/hydroxide, etc., can solve problems such as difficult separation, difficult recovery of titanium resources, and difficult control of slag iron, etc., to achieve The effects of high grade titanium slag, great economic advantages, and great environmental protection advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of pre-reduction-electric furnace deep reduction-fluorination method comprehensively utilizes the technology of vanadium-titanium magnetite, comprising the following steps:

[0031] (1) Pre-reduce the vanadium-titanium magnetite oxidized pellets to obtain the main chemical composition content of the vanadium-titanium magnetite pre-reduced pellets: TFe: 71.38%, MFe=64.56%, TiO 2 : 15.53%, V 2 o 5 :0.82%, SiO 2 =3.71%, vanadium-titanium-magnetite pre-reduced pellets with a metallization rate of 90.45%; put the vanadium-titanium-magnetite pre-reduced pellets, limestone, and reducing agent into the electric furnace for deep reduction smelting, and quicklime is added according to the pre-mixed alkali Degree 1.2, smelting temperature 1550°C, smelting time 60min, separated to obtain vanadium-containing pig iron and TiO 2 51.6% titanium-containing slag;

[0032] (2) Gained vanadium-containing molten iron is used for vanadium extraction in converter or separated semi-...

Embodiment 2

[0036] A kind of pre-reduction-electric furnace deep reduction-fluorination method comprehensively utilizes the technology of vanadium-titanium magnetite, comprising the following steps:

[0037] (1) Pre-reduce the vanadium-titanium magnetite oxidized pellets to obtain the main chemical composition content of the vanadium-titanium magnetite pre-reduced pellets: TFe: 71.38%, MFe=64.56%, TiO 2 : 15.53%, V 2 o 5 :0.82%, SiO 2 =3.71%, vanadium-titanium-magnetite pre-reduced pellets with a metallization rate of 90.45%; put the vanadium-titanium-magnetite pre-reduced pellets, limestone, and reducing agent into the electric furnace for deep reduction smelting, and quicklime is added according to the pre-mixed alkali The temperature is 1.4, the smelting temperature is 1600℃, and the smelting time is 40min, and the vanadium-containing pig iron and TiO are separated 2 50.3% titanium-containing slag;

[0038] (2) Gained vanadium-containing molten iron is used for vanadium extraction ...

Embodiment 3

[0042] A kind of pre-reduction-electric furnace deep reduction-fluorination method comprehensively utilizes the technology of vanadium-titanium magnetite, comprising the following steps:

[0043] (1) Pre-reduce the vanadium-titanium magnetite oxidized pellets to obtain the main chemical composition content of the vanadium-titanium magnetite pre-reduced pellets: TFe: 71.38%, MFe=64.56%, TiO 2 : 15.53%, V 2 o 5 :0.82%, SiO 2 =3.71%, vanadium-titanium-magnetite pre-reduced pellets with a metallization rate of 90.45%; put the vanadium-titanium-magnetite pre-reduced pellets, limestone, and reducing agent into the electric furnace for deep reduction smelting, and quicklime is added according to the pre-mixed alkali The temperature is 1.5, the smelting temperature is 1650°C, and the smelting time is 20 minutes, and the vanadium-containing pig iron and TiO are separated 2 49.7% titanium-containing slag;

[0044] (2) Gained vanadium-containing molten iron is used for vanadium extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com