Glow-type chemiluminescent sensor based on hydrogel and its preparation method and application

A chemiluminescence and hydrogel technology, applied in chemiluminescence/bioluminescence, analysis by chemical reaction of materials, etc., can solve problems such as limited application, complex electrode modification process equipment and equipment, etc., to enhance chemiluminescence intensity , The effect of long chemiluminescence time and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

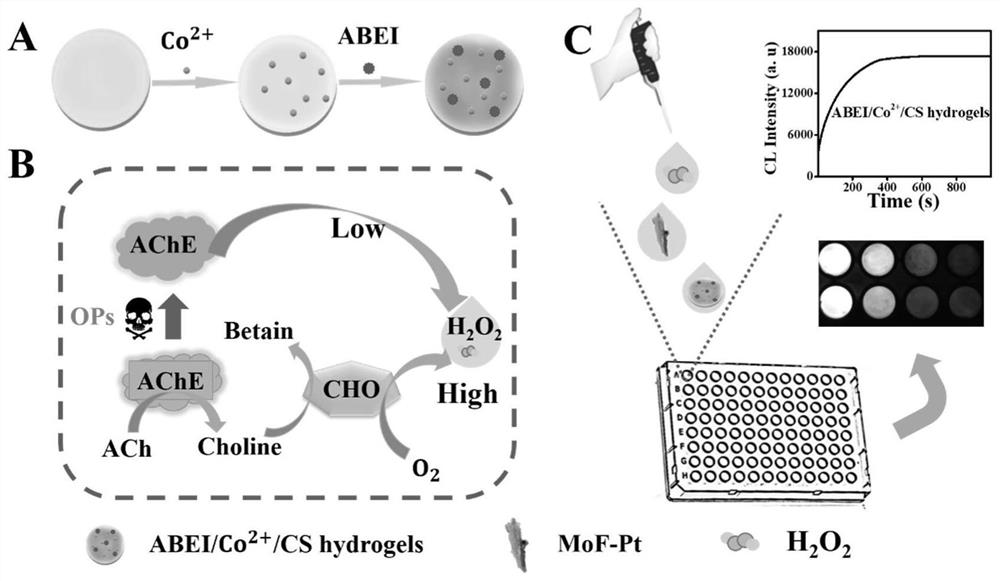

[0049] Example 1 ABEI / Co 2+ Synthesis of / CS hydrogel

[0050] In 15mL alkaline solution (mass ratio is LiOH: KOH: urea: H 2 (O=4.5:7:8:80.5) stirring and dispersing 0.4g chitosan powder, adding 0.6mL CoCl 2 (1mM) solution, stirred for 5 minutes, and refrigerated at -20°C until completely frozen. After thawing at room temperature, 1.5 mL of ABEI (10 mM) solution was added and stirred for 5 hours to uniformly disperse in the system to obtain ABEI / Co 2+ / CS hydrogel and store at 4 °C.

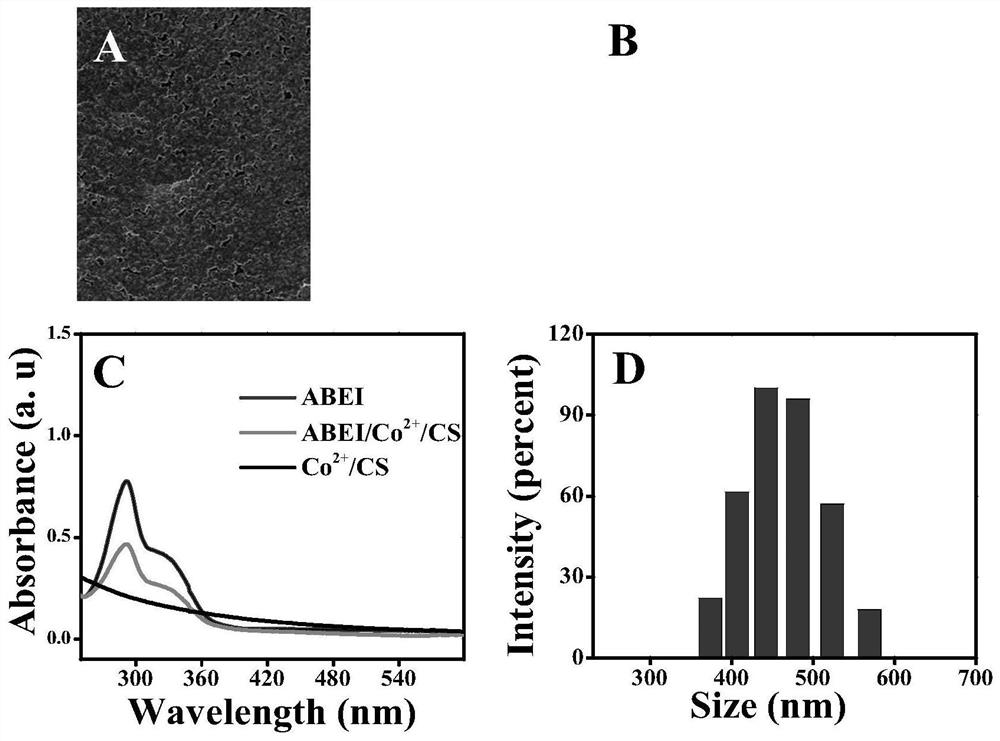

[0051] figure 2 A shows the synthetic ABEI / Co 2+ / CS SEM image of the hydrogel; the characteristic absorption peak of ABEI is located at the red line at 291nm, and the ultraviolet-visible absorption spectrum proves that ABEI is successfully wrapped in the hydrogel.

Embodiment 2

[0052] Example 2 ABEI / Co 2+ Synthesis of / CS hydrogel

[0053] In 15mL alkaline solution (mass ratio is LiOH: KOH: urea: H 2 (O=4.5:7:8:80.5) stirring and dispersing 0.4g chitosan powder, adding 0.6mL CoCl 2 (0.1 mM) solution, stirred for 5 minutes, and refrigerated at -20°C until completely frozen. After thawing at room temperature, add 1.5mL ABEI (4mM) solution and stir for 5 hours to be uniformly dispersed in the system to obtain ABEI / Co 2+ / CS hydrogel and store at 4 °C.

Embodiment 3

[0054] Example 3 Synthesis of MOF-Pt

[0055] First, weigh 0.2g of TCPP, 0.12g of AlCl 3 ·3H 2 The CTAB of O and 0.144g was dissolved in 20mL water, stirred for 10 minutes and placed in a 20mL reactor, then reacted at 180°C for 16 hours, after centrifuging at 3000rpm, the supernatant was centrifuged at 13000rpm to obtain a precipitate. The precipitate was washed twice with DMF, water and acetone, respectively, and then dried overnight in vacuum. Then, purple and black precipitates were obtained by vacuum drying at 150°C for 7 hours for further reaction. Then weigh 0.038g of precipitate and 0.064g of Cu(Ac) 2 It was dissolved in 8ml of DMF organic solvent, stirred for 10 minutes, then poured into a 20mL reaction kettle, and reacted at 100°C for 24 hours to obtain a red-black blocky precipitate. After centrifugation at 13000rpm, the precipitate was washed twice with DMF, water and acetone, and then dried in vacuo overnight to obtain product 1.

[0056] Finally, 0.5ml of H ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com