System for synchronously recovering carbon dioxide and nitrogen from boiler flue gas in coal-fired power plant

A technology of carbon dioxide and boiler flue gas, which is applied in the system field of simultaneous recovery of carbon dioxide and nitrogen from coal-fired boiler flue gas, can solve the problems of incomplete treatment of carbon dioxide and nitrogen, inability to purify carbon dioxide and nitrogen, and inconvenient maintenance, so as to achieve stable operation of equipment High performance, easy maintenance, not easy to clog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The invention is applied to the collection and recovery of flue gas from coal-fired boilers meeting the national ultra-low emission standards. The flue gas conditions of the coal-fired boiler in this embodiment are: the flue gas temperature is 50°C, the carbon dioxide content in the flue gas is 13%, the nitrogen content in the flue gas is 71%, the oxygen content in the flue gas is 6%, the flue gas The content of sulfur dioxide is 35mg / Nm 3, the content of nitrogen oxides in flue gas is 50mg / Nm 3 , The content of water vapor in the flue gas is 12%.

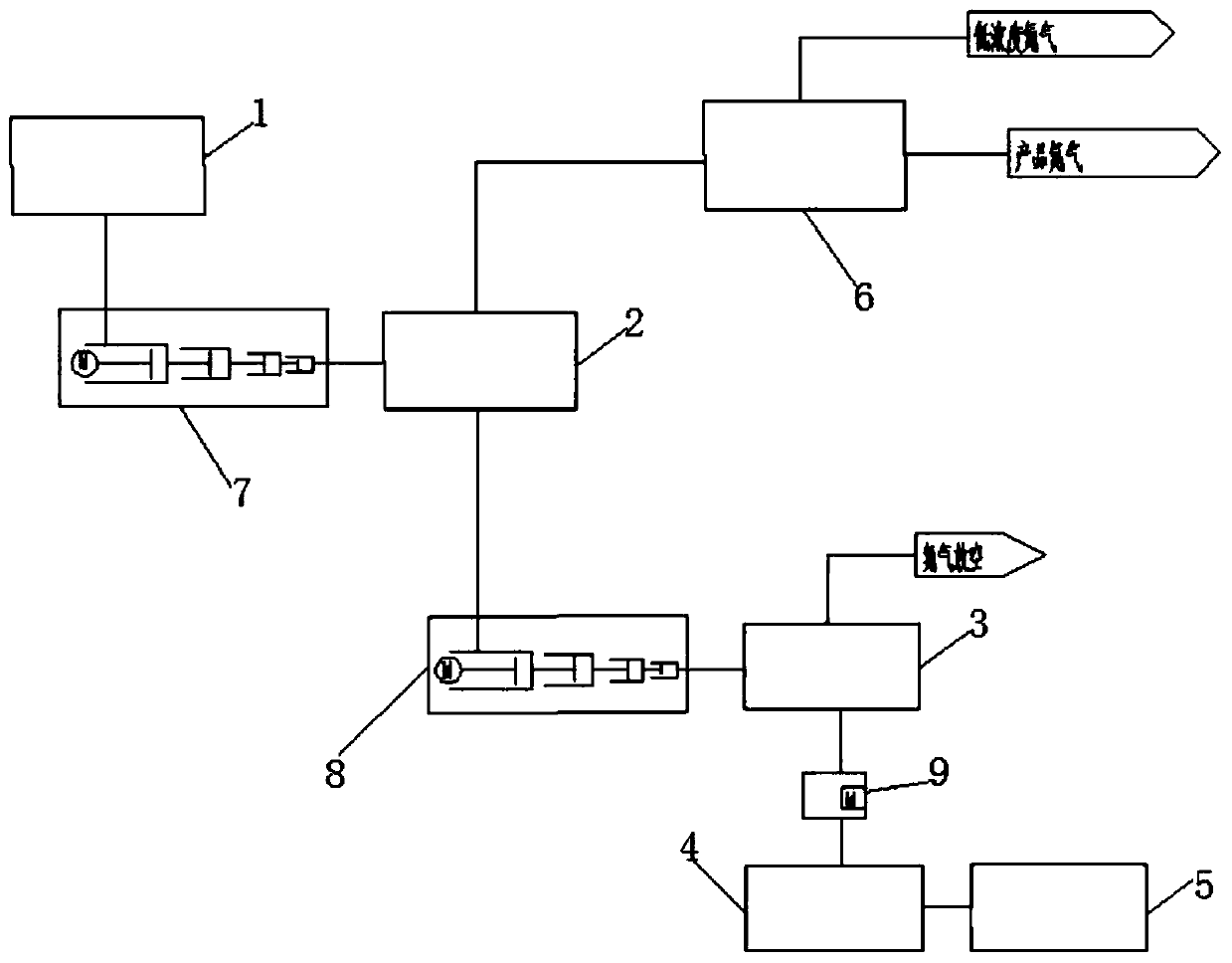

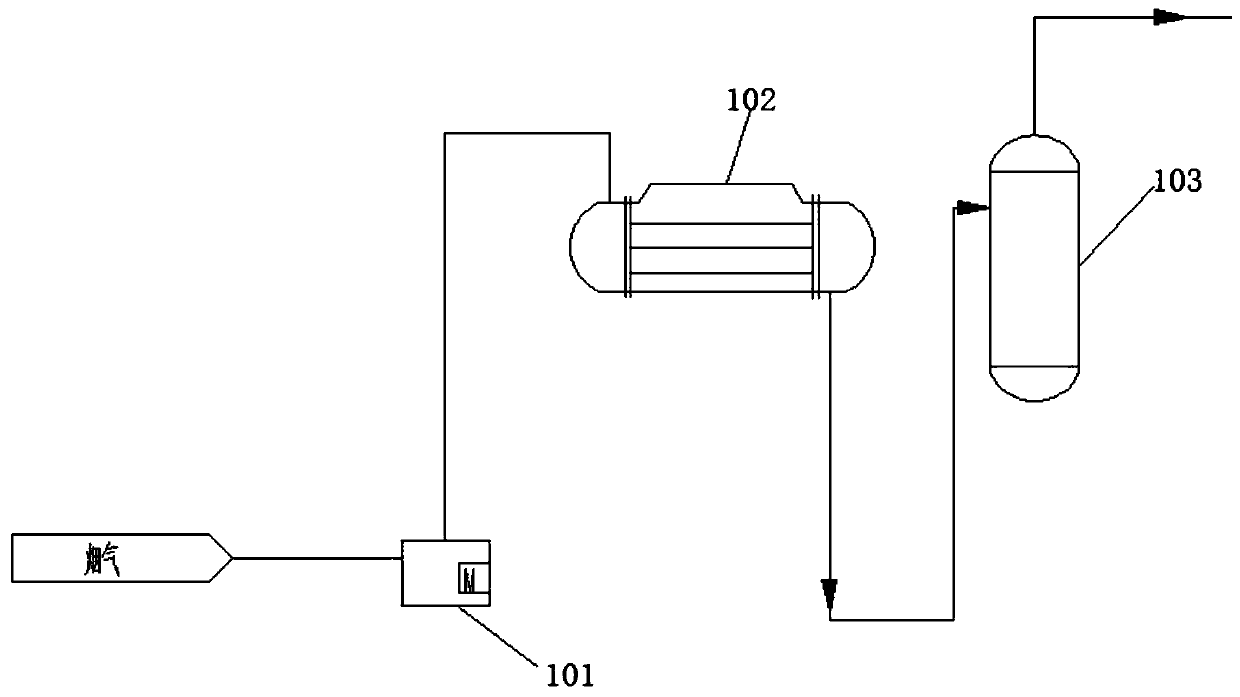

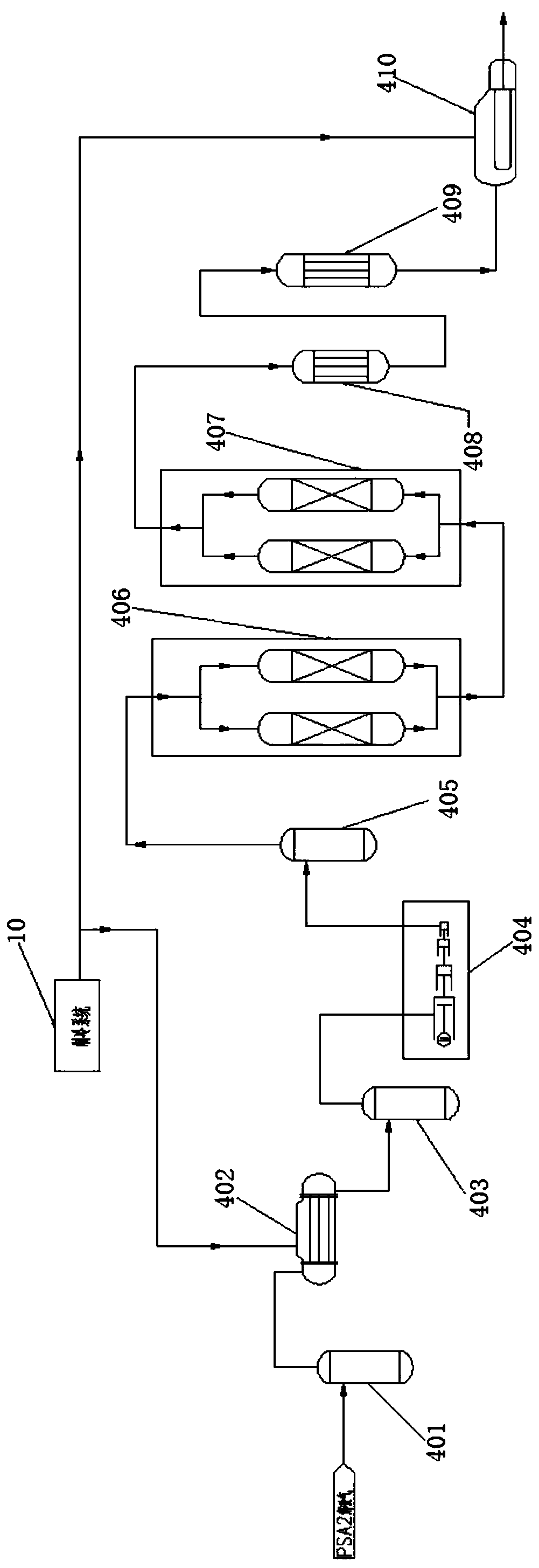

[0027] Such as figure 1 As shown, the present invention includes a flue gas pretreatment system 1, a PSA1 system 2, a PSA2 system 3, a carbon dioxide compression purification system 4, a carbon dioxide rectification storage system 5, and a PSA high-purity nitrogen system 6. The flue gas pretreatment system 1 is used to cool down and dehydrate the flue gas from the boiler; the PSA1 system 2 is used to discharge nitrogen an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com