Method for preparing cesium-doped mixed perovskite solar cell in air environment

A technology of solar cells and air environment, applied in the field of solar cells, can solve the problems of unfavorable large-scale production of perovskite solar cells, small operation space, expensive glove box, etc., achieves excellent photoelectric conversion efficiency, smooth surface, and is beneficial to The effect of mass production applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

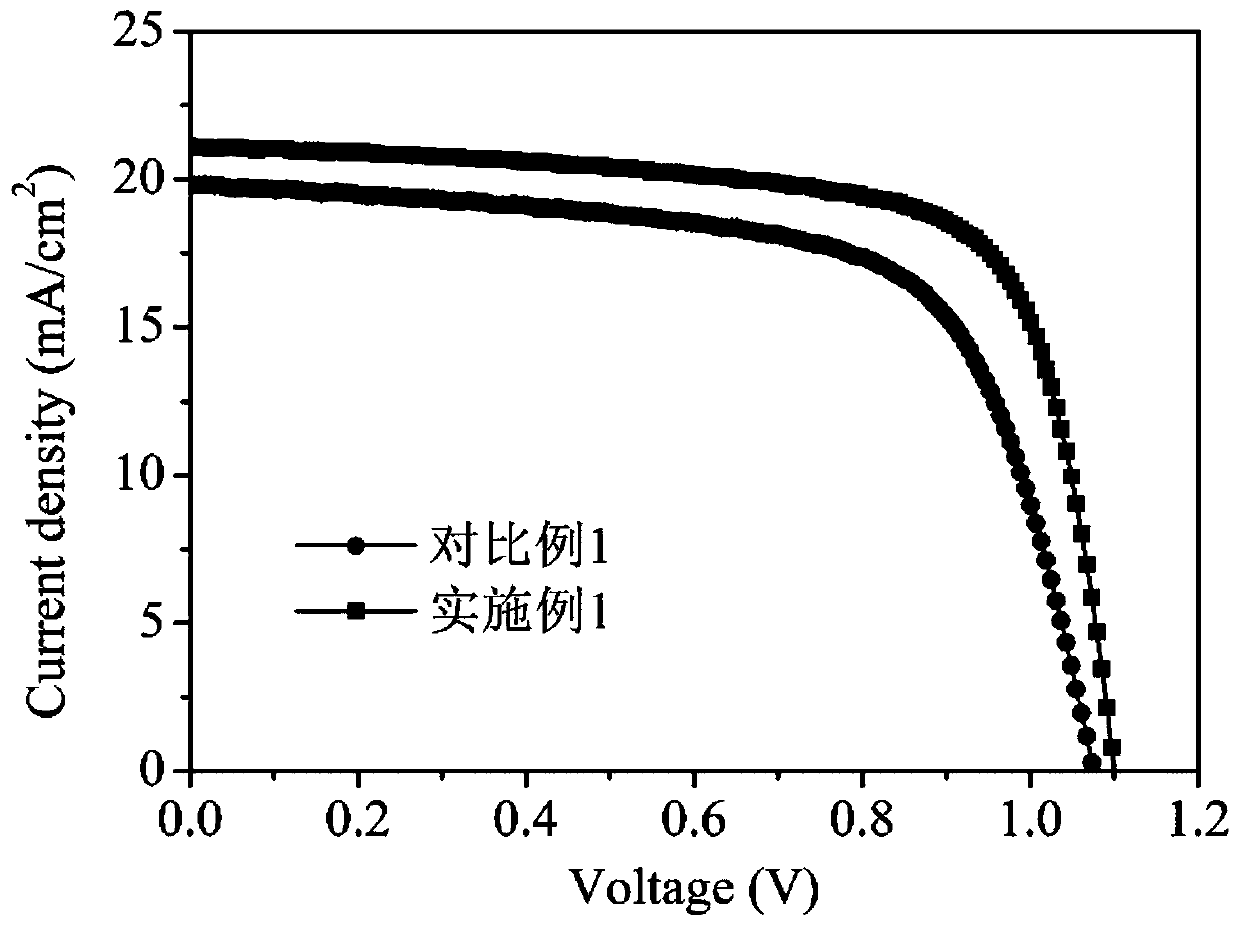

[0032] Example 1: Mixed-cation perovskite solar cells doped with 5% cesium

[0033] 1) The FTO glass was ultrasonically cleaned with alkaline detergent, deionized water, acetone, absolute ethanol and isopropanol for 30 min, and finally dried and treated with UV-ozone.

[0034] 2) Preparation of TiO on FTO glass substrate 2 Dense layer, the precursor solution includes the following components: tetraisopropyl titanate (0.3mol / L), acetylacetone (0.45mol / L), hydrochloric acid (0.09mol / L), water (1.8mol / L), and the solvent is ethanol.

[0035] 3) Absorb the precursor solution, drop it on the cleaned FTO glass substrate, make the solution cover the entire FTO surface, and form a film by spin coating, the spin coating speed is 3000rpm, and the time is 20s. Then sinter at 510 °C for 30 min in a muffle furnace or a hot plate.

[0036] 4) will cover TiO 2 The dense layer of FTO glass soaked in a certain concentration of TiCl 4 In the aqueous solution, keep warm at 70°C for 40 minut...

Embodiment 2

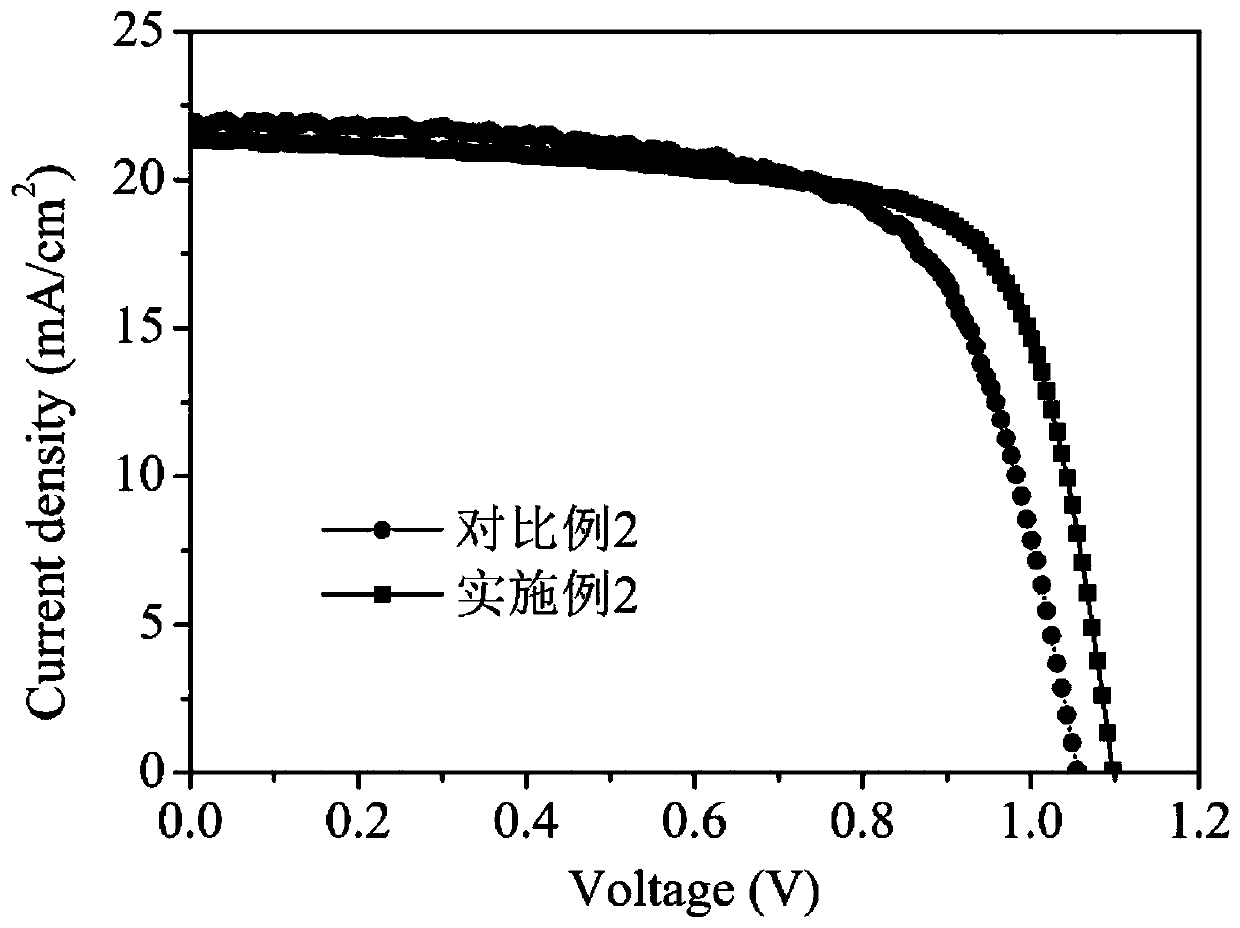

[0046] Example 2: Preparation of a mixed cation perovskite solar cell doped with 5% cesium in a relatively dry environment.

[0047] A mixed cation perovskite solution doped with 5% cesium is configured in a relatively dry air environment (temperature 18-23° C., relative humidity ≤ 30%), and the perovskite thin film is prepared. Concrete steps are consistent with embodiment 1.

Embodiment 3

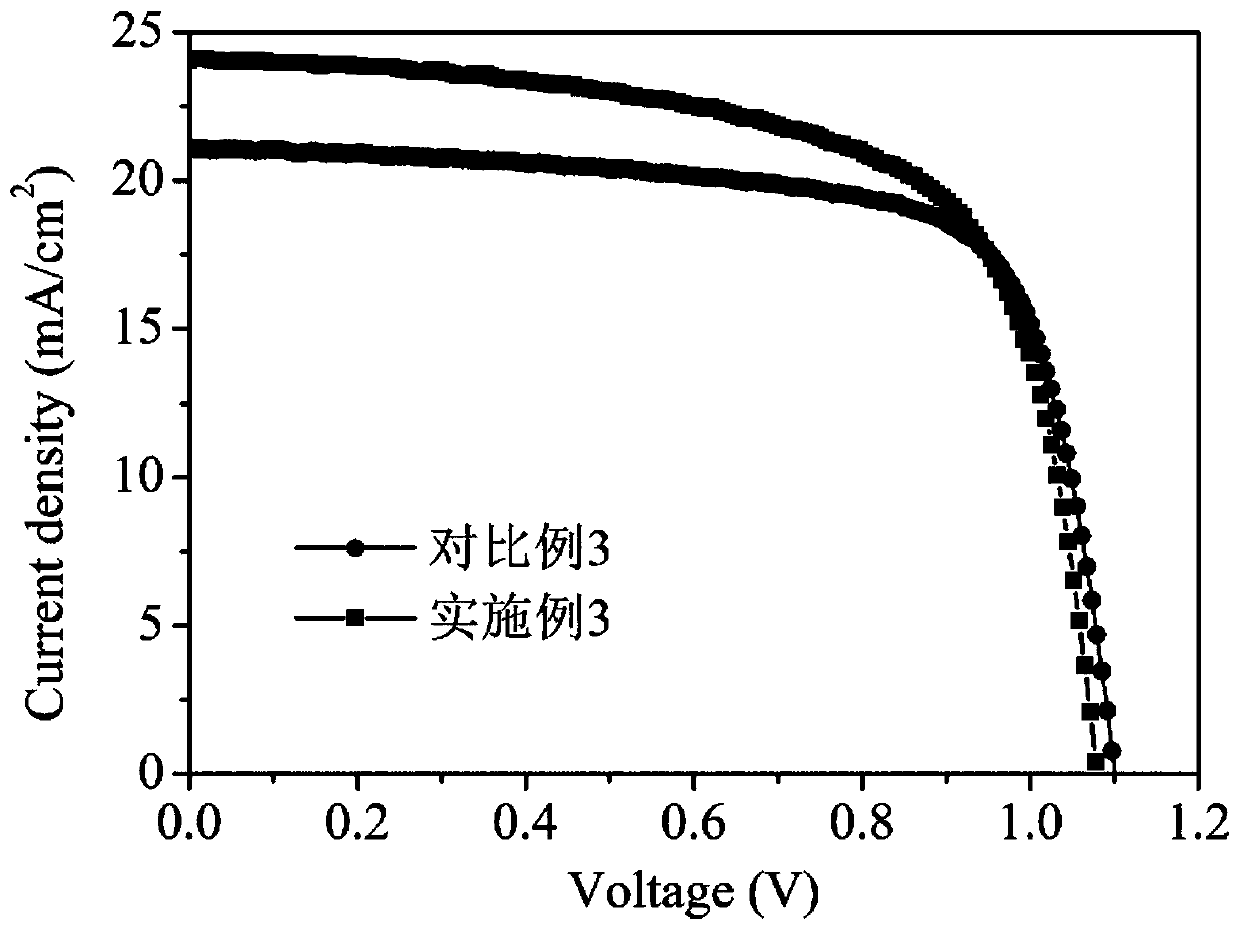

[0051] Example 3: A mixed cation perovskite solar cell doped with 5% cesium, the evaporation rate of the silver electrode is 1000 angstroms / second, and the evaporation thickness is 1200 angstroms, that is, 1200 angstroms of silver metal is evaporated within two seconds. All the other operations and preparation techniques are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com