lm/ta-chitosan hydrochloride composite nanoparticles, its preparation method and application

A technology of composite nanoparticles and chitosan hydrochloride, applied in the field of emulsifiers, can solve the problems of loss of nutritional quality, affecting product storage stability and sensory properties, susceptibility to unstable oxidative degradation, etc., to improve stability , The effect of low preparation cost, excellent oxidation resistance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1 The preparation method of a kind of Pickering emulsion that the present embodiment relates to comprises the steps:

[0055] 1. Preparation of low methoxyl pectin / tannic acid colloidal complex

[0056] The low methoxyl pectin / tannic acid colloidal complex was prepared at room temperature 25°C and 200rpm magnetic stirring. Briefly, a 0.2 wt% aqueous tannic acid solution was added by mixing with a pipette tip with an aqueous solution of 0.8 wt% low-methoxyl pectin in which the concentration of tannic acid The mass ratio is 1:0. Use 0.1M HCl solution (0.1M HCl) or other acid solutions to adjust the pH value of the tannic acid and low methoxy pectin dispersion to 4.5, and then stir at room temperature for 2 hours to obtain low methoxy Pectin / tannin colloidal complex.

[0057] 2. Preparation of low-methoxy pectin / tannic acid-chitosan hydrochloride composite nanoparticles

[0058] First weigh chitosan hydrochloride powder and disperse it in distilled water, pl...

Embodiment 2

[0062] Embodiment 2 The preparation method of a kind of Pickering emulsion that the present embodiment relates to comprises the steps:

[0063] 1. Preparation of low methoxyl pectin / tannic acid colloidal complex

[0064] The low methoxyl pectin / tannic acid colloidal complex was prepared at room temperature 25°C and 250rpm magnetic stirring. Briefly, a 1.0 wt% aqueous tannic acid solution was added by mixing with a pipette tip with an aqueous solution of 0.85 wt% low-methoxyl pectin, in which low-methoxyl pectin was mixed with tannic acid, under magnetic stirring. The mass ratio is 1:0.4. The pH of the tannic acid and low-methoxyl pectin dispersion was adjusted to 5 using 0.1 M HCl, and then stirred at room temperature for 3 hours to obtain low-methoxyl pectin / tannic acid colloidal complexes.

[0065] 2. Preparation of low-methoxy pectin / tannic acid-chitosan hydrochloride composite nanoparticles

[0066] First weigh chitosan hydrochloride powder and disperse it in distilled ...

Embodiment 3

[0070] Embodiment 3 The preparation method of a kind of Pickering emulsion that the present embodiment relates to comprises the following steps:

[0071] 1. Preparation of low methoxyl pectin / tannic acid colloidal complex

[0072] The low methoxyl pectin / tannic acid colloidal complex was prepared at room temperature 25°C and 300rpm magnetic stirring. Briefly, a 0.5 wt% aqueous tannic acid solution was added by mixing with a pipette tip with an aqueous solution of 1.0 wt% low-methoxyl pectin, in which low-methoxyl pectin was mixed with tannic acid, under magnetic stirring. The mass ratio is 1:1. The pH of the tannic acid and low-methoxyl pectin dispersion was adjusted to 5.5 using 0.1 M HCl, and then stirred at room temperature for 2.5 hours to obtain low-methoxyl pectin / tannic acid colloidal complexes.

[0073] 2. Preparation of low-methoxy pectin / tannic acid-chitosan hydrochloride composite nanoparticles

[0074]First weigh chitosan hydrochloride powder and disperse it in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

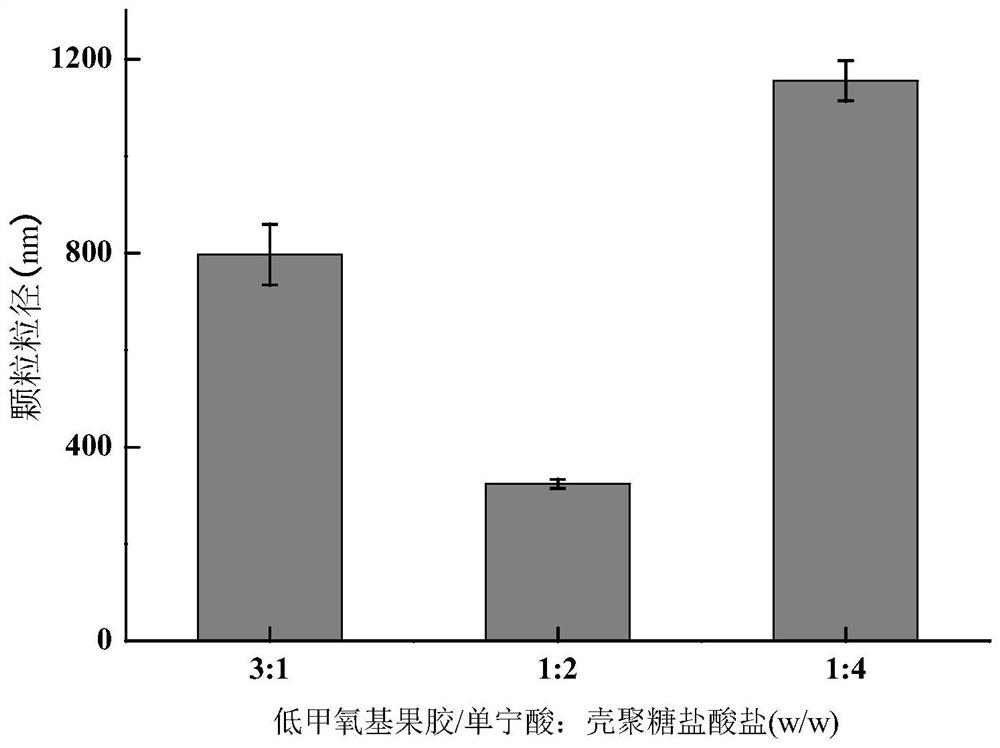

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com