CMC/FA-chitosan hydrochloride composite nanoparticle, and preparation method and application thereof

A technology of chitosan hydrochloride and composite nanoparticles, which is applied in the field of emulsifiers to achieve low cost, good physical stability, and the effect of preventing droplet aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Preparation of carboxymethyl cellulose / ferulic acid complex

[0050] The carboxymethyl cellulose was dissolved in distilled water to obtain a 0.1 wt% carboxymethyl cellulose solution. The solution was continuously stirred at 250 rpm for 1 hour, and the pH was adjusted to 4. EDC and ferulic acid are dissolved in ethanol, its mixed solution is added dropwise in the carboxymethyl cellulose solution 250rpm continuous stirring 1 hour, the mol ratio of ferulic acid and carboxymethyl cellulose is 1:3 (the concrete dosage is respectively For: 10mg, 30mg), and the pH of the solution was adjusted to 4 using 0.1M hydrochloric acid.

[0051] 2. Preparation of carboxymethyl cellulose / ferulic acid-chitosan hydrochloride composite nanoparticles

[0052] Chitosan hydrochloride is placed on the stirrer and stirred and dissolved and the pH is adjusted to be 4 to obtain 0.2wt% chitosan hydrochloride solution; Ferulic acid complex solution was added dropwise to chitosan hydrochloride ...

Embodiment 2

[0057] 1. Preparation of carboxymethyl cellulose / ferulic acid complex

[0058] Carboxymethyl cellulose was dissolved in distilled water to obtain a 0.1 wt% carboxymethyl cellulose solution, stirred continuously at 250 rpm for 1 hour, and the pH was adjusted to 4. ED and ferulic acid are dissolved in ethanol, its mixed solution is added dropwise in the carboxymethyl cellulose solution 250rpm continuous stirring 1 hour, the mol ratio of ferulic acid and carboxymethyl cellulose is 1:2 (the specific dosage is respectively For: 10mg, 20mg), and use 0.1M hydrochloric acid to adjust the pH of the solution to 4.

[0059] 2. Preparation of carboxymethyl cellulose / ferulic acid-chitosan hydrochloride composite nanoparticles

[0060] Chitosan hydrochloride is placed on the stirrer and stirred and dissolved and the pH is adjusted to be 4 to obtain 0.2wt% chitosan hydrochloride solution; Ferulic acid complex solution was added dropwise to chitosan hydrochloride solution to obtain carboxym...

Embodiment 3

[0065] 1. Preparation of carboxymethyl cellulose / ferulic acid complex

[0066] Carboxymethyl cellulose was dissolved in distilled water to obtain a 0.1 wt% carboxymethyl cellulose solution, stirred continuously at 250 rpm for 1 hour, and the pH was adjusted to 4. ED and ferulic acid are dissolved in ethanol, its mixed solution is added dropwise in the carboxymethyl cellulose solution 250rpm continuous stirring 1 hour, the mol ratio of ferulic acid and carboxymethyl cellulose is 2:1 (the concrete consumption is respectively For: 20mg, 10mg), and the pH of the solution was adjusted to 4 using 0.1M hydrochloric acid.

[0067] 2. Preparation of carboxymethyl cellulose / ferulic acid-chitosan hydrochloride composite nanoparticles

[0068] Chitosan hydrochloride is placed on the stirrer and stirred and dissolved and the pH is adjusted to be 4 to obtain 0.2wt% chitosan hydrochloride solution; Ferulic acid complex solution was added dropwise to chitosan hydrochloride solution to obtai...

PUM

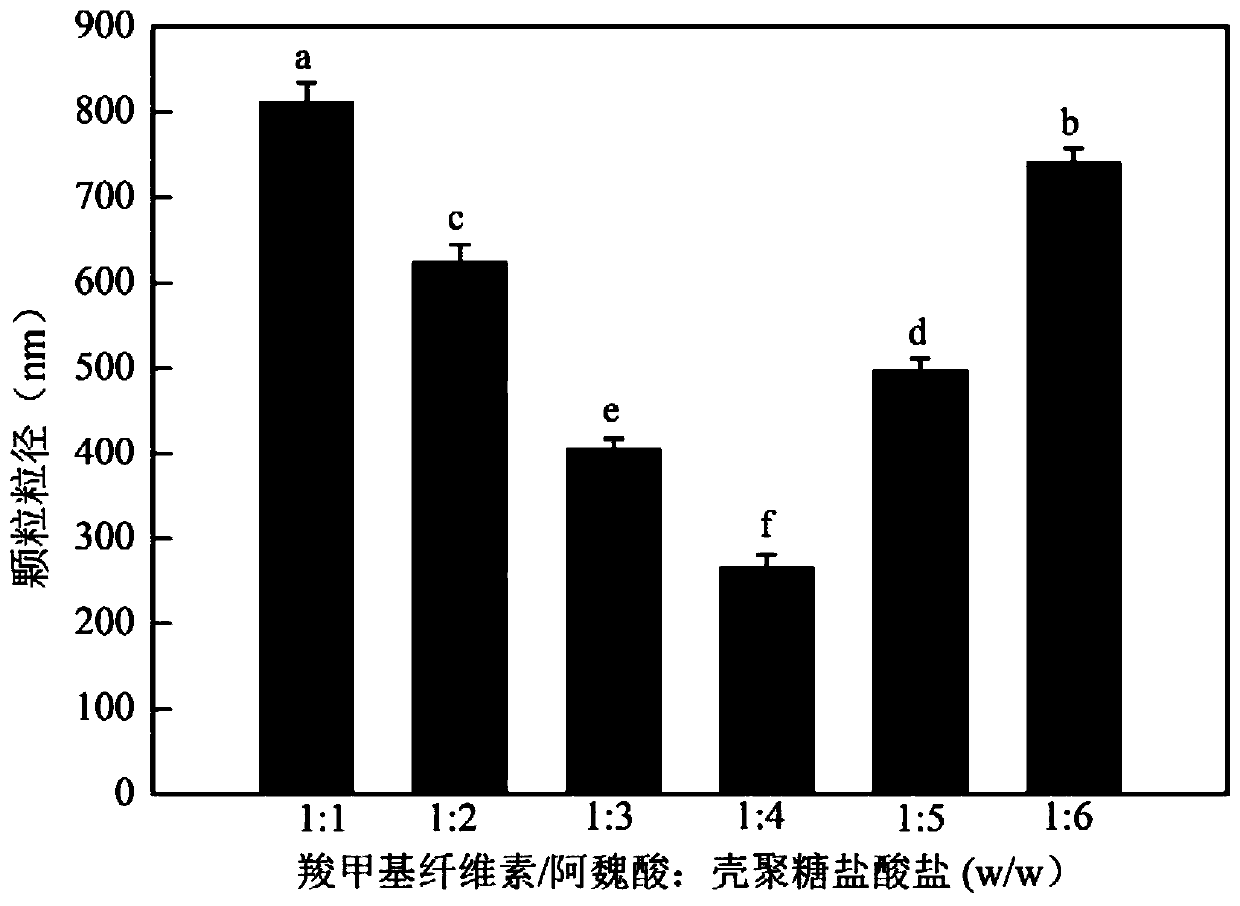

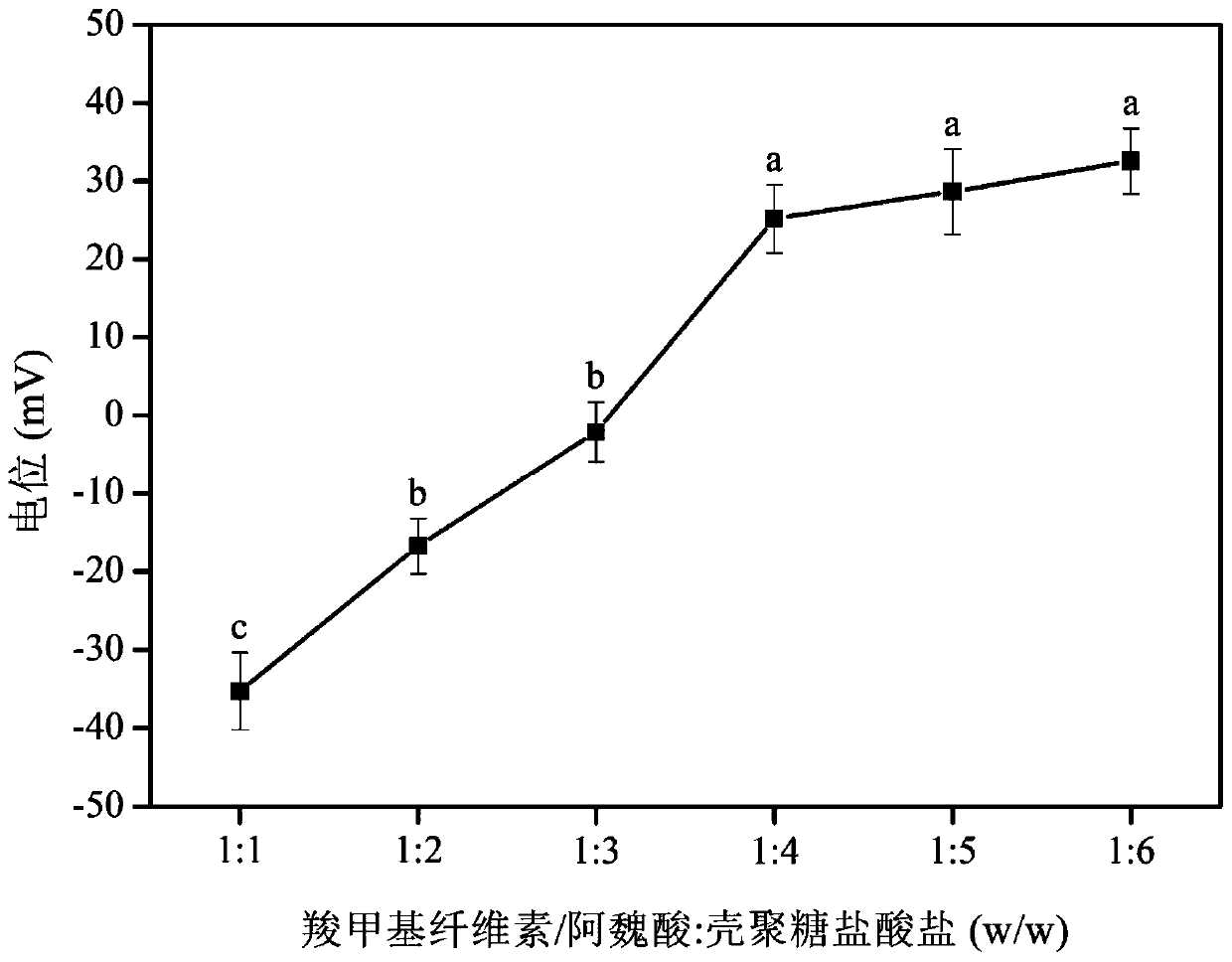

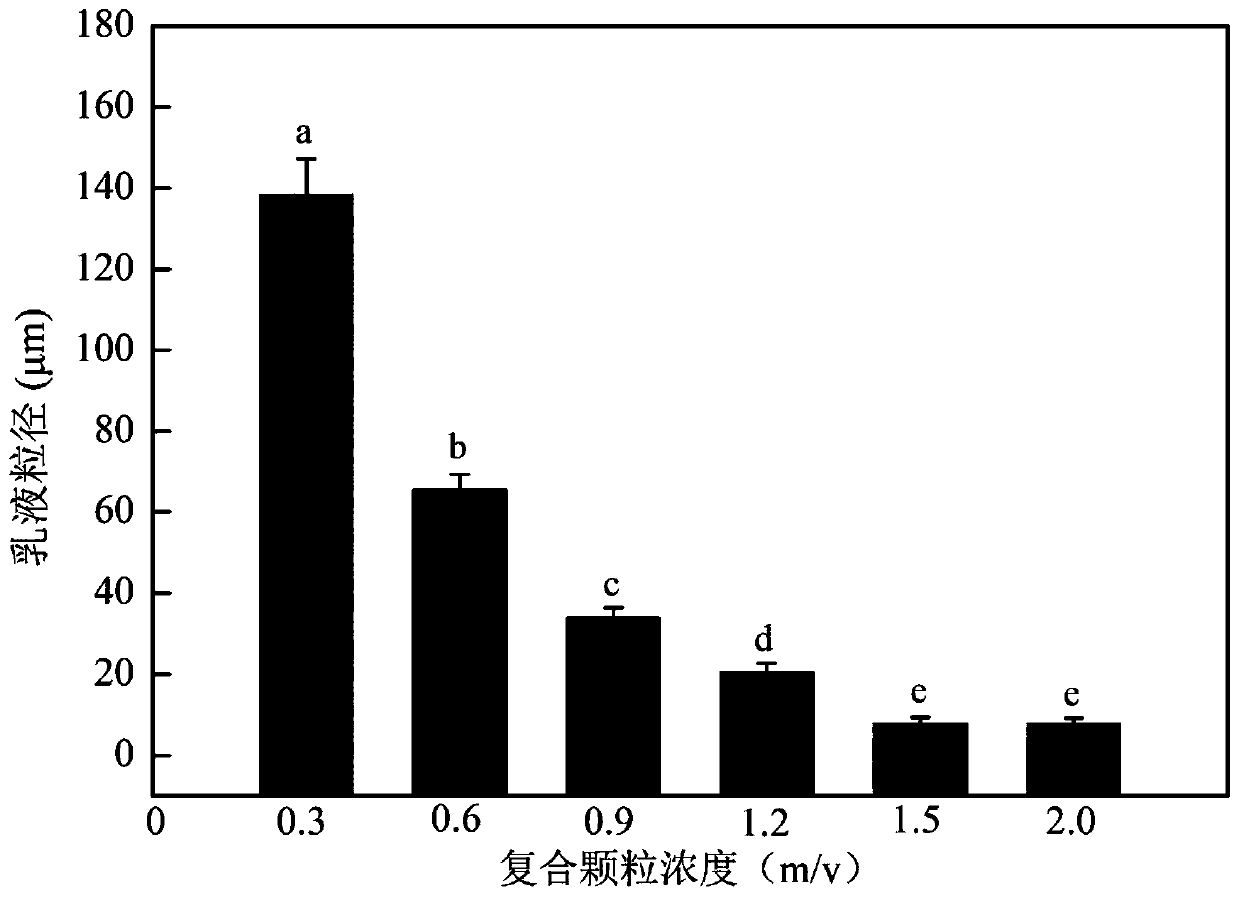

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com