An ecological fattening method for high-quality beef cattle

A cattle and ecological technology, applied in the field of breeding, can solve the problems of high proportion of beef ketone body fat, high incidence of cattle fattening period, insufficient exercise of cattle, etc., to improve digestion and absorption rate, improve cattle's own resistance, reduce cattle effect of disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

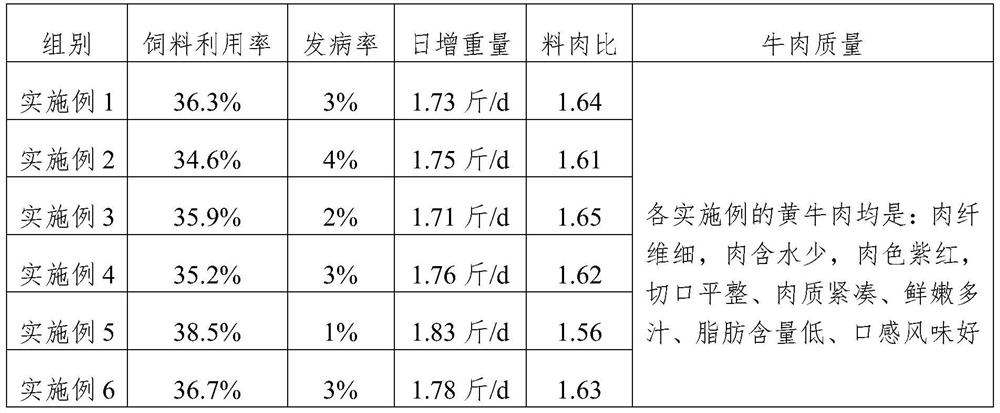

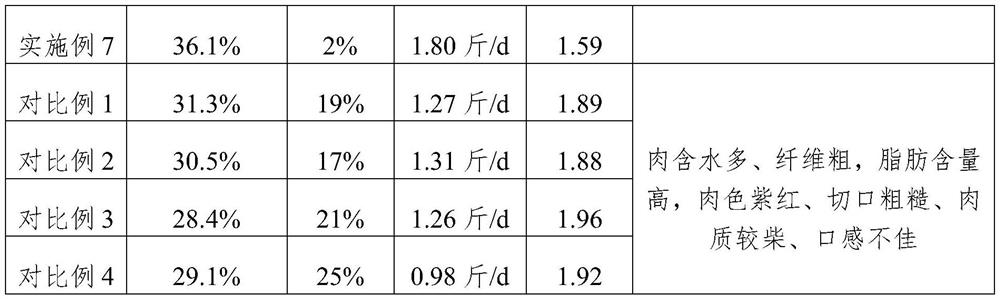

Examples

Embodiment 1

[0044] An ecological fattening method for high-quality beef cattle, the ecological fattening method includes fattening management, daily management and pest control, specifically comprising the following steps:

[0045] (1) Feeding management: including the early stage of fattening, the middle stage of fattening and the late stage of fattening;

[0046] Pre-fattening period: Feed twice a day in the morning and evening in the pre-fattening period, half full in the morning and full in the evening;

[0047] Mid-fattening period: Feed mid-fattening feed twice a day in the morning and evening, half full in the morning and full in the evening;

[0048] Late fattening: Feed the late fattening feed three times a day in the morning, middle and evening, half full at noon, and full in the morning and evening;

[0049] The feed in the early stage of fattening is made of the following raw materials in parts by weight: 80-100 parts of yellow corn flour, 80-100 parts of rice bran, 65-85 par...

Embodiment 2

[0058] The difference from Example 1 is that the feed in the early stage of fattening is made of the following raw materials in parts by weight: 90 parts of yellow corn flour, 90 parts of rice bran, 75 parts of wine tank, 90 parts of sweet potato vines, 100 parts of chicory, and 100 parts of ryegrass , 85 parts of Giant Junction Grass, 85 parts of Sweet Elephant Grass, 20 parts of Bacillus subtilis, 15 parts of Aspergillus oryzae, and 15 parts of Lactobacillus plantarum. Grass is crushed to pass through a 20-mesh sieve, and then other raw materials are added to mix evenly, stacked and fermented at 23°C for 23 days, dried and granulated, and other conditions remain unchanged.

Embodiment 3

[0060] The difference from Example 1 is that the mid-term feed for fattening is made of the following raw materials in parts by weight: 85 parts of lavender, 110 parts of yellow corn flour, 110 parts of rice bran, 55 parts of wine tank, 75 parts of peanut bran, 55 parts of bean curd residue 85 parts, 85 parts of ryegrass, 85 parts of giant fungus grass, 85 parts of bitter hemp, 20 parts of Bacillus subtilis, 10 parts of protease, and 10 parts of yeast. Ma Cai is crushed to pass through a 20-mesh sieve, and then other raw materials are added to mix evenly, stacked and fermented at 22°C for 23 days, dried and granulated, and other conditions remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com