Mechanical ball milling synthesis method of phosphorus pentasulfide powder

A technology of phosphorus pentasulfide and phosphorus pentachloride, which is applied in the direction of phosphorus sulfur/selenium/tellurium phosphorus compounds, can solve the problems of low product quality, complicated preparation process, and high energy consumption, and achieve low cost, efficient synthesis method, and environmental protection. friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

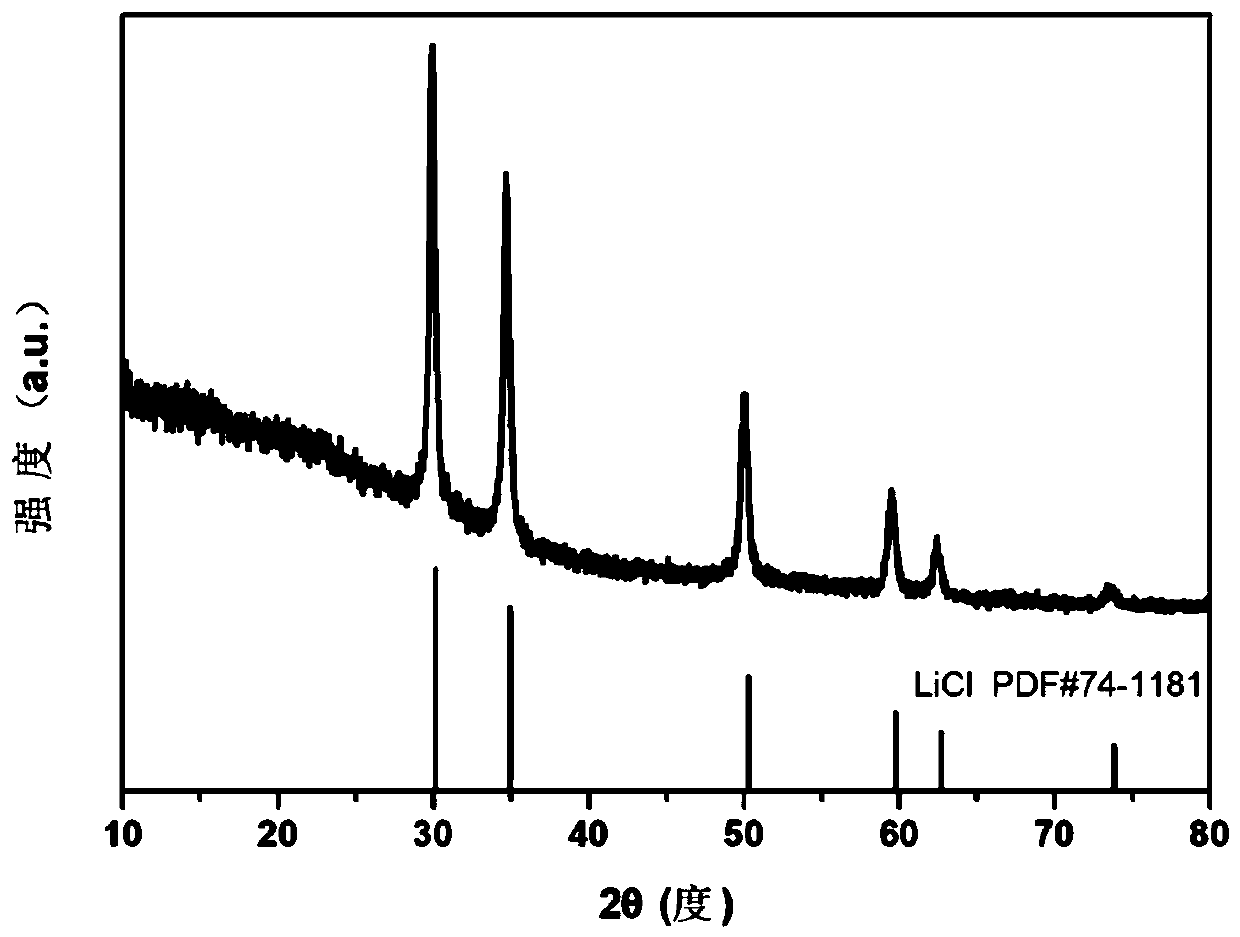

[0026] Under the protection of an argon atmosphere, 0.75g of lithium sulfide powder and 1.32g of phosphorus pentachloride were evenly mixed and then added to a ball mill jar. Then put the balls into the ball mill jar and seal it. The ratio of the total mass of grinding balls to the total mass of materials is 40:1. Under the condition of room temperature, the ball mill jar was continuously ball milled at a speed of 500 r / min for 24 hours. After the reaction, under an argon atmosphere, the solid product in the ball mill tank was taken out and added to toluene for solid-liquid separation, and the separated solution was distilled at 150°C to recover liquid toluene and solid phosphorus pentachloride. Add the remaining solid into acetone, separate the solid from the liquid, and dry the solid at 80°C to obtain phosphorus pentasulfide powder. figure 1 The X-ray diffraction pattern of its product can only characterize the X-ray spectrum of lithium chloride. According to the law of co...

Embodiment 2

[0028] Under the protection of an argon atmosphere, 1.78g of lithium sulfide powder and 4.9g of phosphorus pentachloride were uniformly mixed and then added to a ball mill jar. Then put the balls into the ball mill jar and seal it. The ratio of the total mass of grinding balls to the total mass of materials is 60:1. Under the condition of room temperature, the ball mill jar was continuously ball milled at a speed of 100 r / min for 100 h. After the reaction, under an argon atmosphere, the solid product in the ball mill tank was taken out and added to toluene for solid-liquid separation, and the separated solution was distilled at 110°C to recover liquid toluene and solid phosphorus pentachloride. Add the remaining solid to acetone, separate the solid from the liquid, and dry the solid at 80°C to obtain phosphorus pentasulfide powder

Embodiment 3

[0030] Under the protection of an argon atmosphere, 0.37g of lithium sulfide powder and 1.3g of phosphorus pentachloride were uniformly mixed and then added to a ball mill jar. Then put the balls into the ball mill jar and seal it. The ratio of the total mass of grinding balls to the total mass of materials is 20:1. Under room temperature conditions, the ball milling tank was continuously ball milled at a speed of 300 r / min for 100 h. After the reaction, under an argon atmosphere, the solid product in the ball mill tank was taken out and added to toluene for solid-liquid separation, and the separated solution was distilled at 120°C to recover liquid toluene and solid phosphorus pentachloride. Add the remaining solid into acetone, separate the solid from the liquid, and dry the solid at 80°C to obtain phosphorus pentasulfide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com