Aeration disc and gasification ash water comprehensive treatment device with same and treatment method

An aeration pan, grey water technology, applied in chemical instruments and methods, degassed water/sewage treatment, water/sewage treatment, etc., can solve problems such as high total hardness, scaling of heat exchangers, and increased pH value , to achieve the effect of mixing efficiency without power, improving aeration efficiency, and reasonable process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

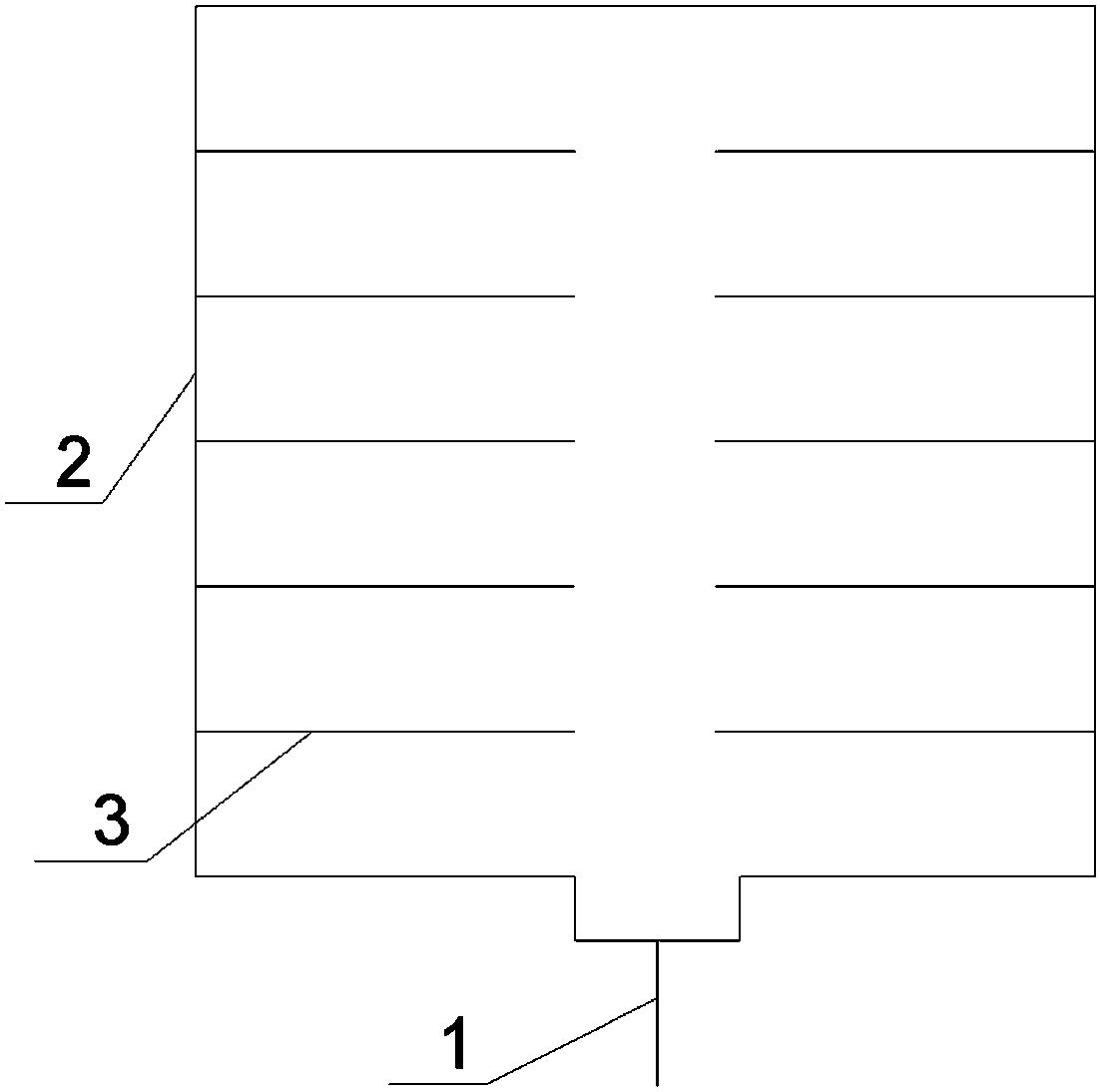

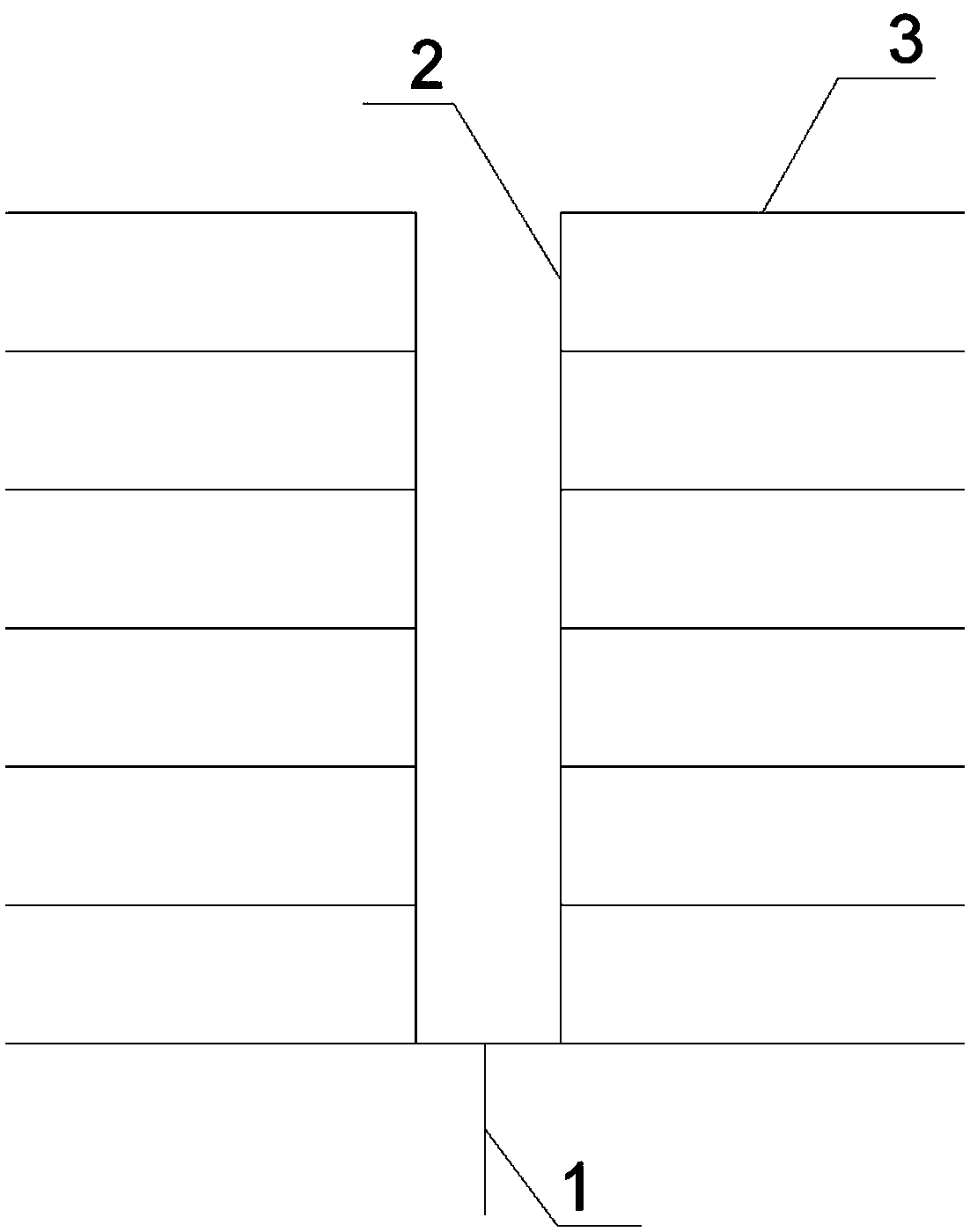

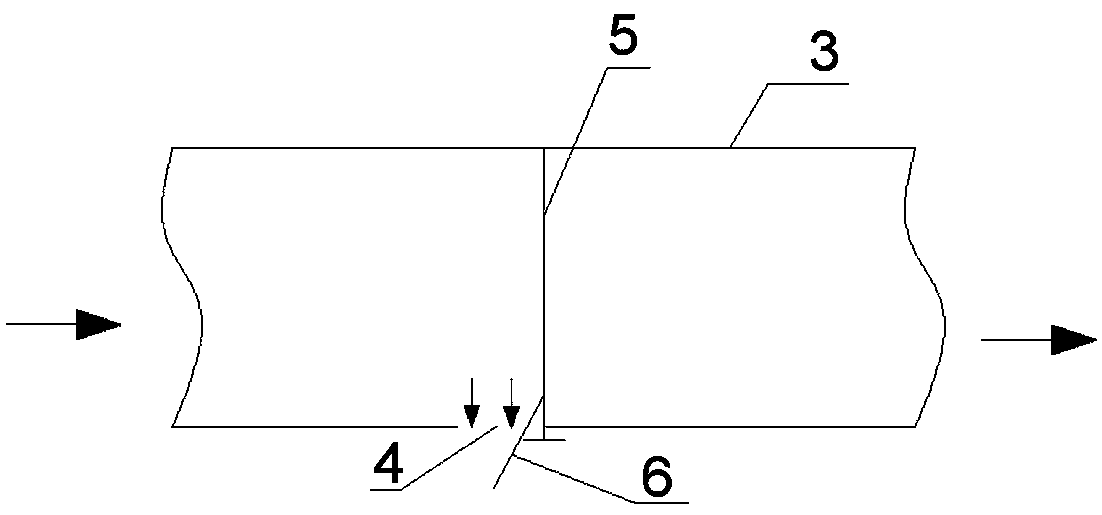

[0044] An aeration pan includes a main pipeline 1 connected with compressed gas, the main pipeline 1 communicates with a sub-pipe 2, the sub-pipe 2 communicates with several branch pipes 3, and the branch pipe 3 is provided with several aeration pipes evenly distributed. Stomata 4; the aeration tray is arranged on the inner bottom of the reaction vessel, and the shape formed by the outer contour of the branch pipe 2 or the outer ends of several branch pipes 3 is compatible with the inner bottom of the reaction vessel; The inner side wall of the branch pipe 3 corresponding to the air hole 4 is provided with a strut 5, and the side of the strut 5 close to the aeration hole 4 is provided with an inclined aeration shrapnel 6, and the end of the aeration shrapnel 6 connected to the strut 5 It is arranged inside the branch pipe 3 , and the other end of the aeration shrapnel 6 is arranged outside the branch pipe 3 , and the middle shape of the aeration shrapnel 6 is adapted to the aer...

Embodiment 2

[0054] An aeration pan and a gasification gray water comprehensive treatment device and treatment method using the aeration pan, wherein the aeration pan includes a main pipeline 1 connected with compressed gas, the main pipeline 1 communicates with a sub-pipe 2, and the sub-pipe 2 communicates with a compressed gas Several branch pipes 3 are connected, and the branch pipes 3 are provided with several aeration holes 4; The shape of the outer end of the outer end is adapted to the inner bottom of the reaction vessel; the inner wall of the branch pipe 3 corresponding to the aeration hole 4 is provided with a strut 5, and the side of the strut 5 near the aeration hole 4 is set There are aeration shrapnel 6 arranged obliquely. One end of the aeration shrapnel 6 connected to the pole 5 is set inside the branch pipe 3, and the other end of the aeration shrapnel 6 is set outside the branch pipe 3. The middle shape of the aeration shrapnel 6 is Compatible with aeration hole 4. The di...

Embodiment 3

[0064] An aeration pan and a gasification gray water comprehensive treatment device and treatment method using the aeration pan, wherein the aeration pan includes a main pipeline 1 connected with compressed gas, the main pipeline 1 communicates with a sub-pipe 2, and the sub-pipe 2 communicates with a compressed gas Several branch pipes 3 are connected, and the branch pipes 3 are provided with several aeration holes 4; The shape of the outer end of the outer end is adapted to the inner bottom of the reaction vessel; the inner wall of the branch pipe 3 corresponding to the aeration hole 4 is provided with a strut 5, and the side of the strut 5 near the aeration hole 4 is set There are aeration shrapnel 6 arranged obliquely. One end of the aeration shrapnel 6 connected to the pole 5 is set inside the branch pipe 3, and the other end of the aeration shrapnel 6 is set outside the branch pipe 3. The middle shape of the aeration shrapnel 6 is Compatible with aeration hole 4. The di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap