A zero-discharge system and process for recycling high-salt and high-cod wastewater

A waste water recovery and zero discharge technology, which is applied in descaling and water softening, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of large fluctuations in water quality, high concentration, complex organic components, etc., and achieve evaporation energy Low consumption, high efficiency of salt separation and high concentration ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

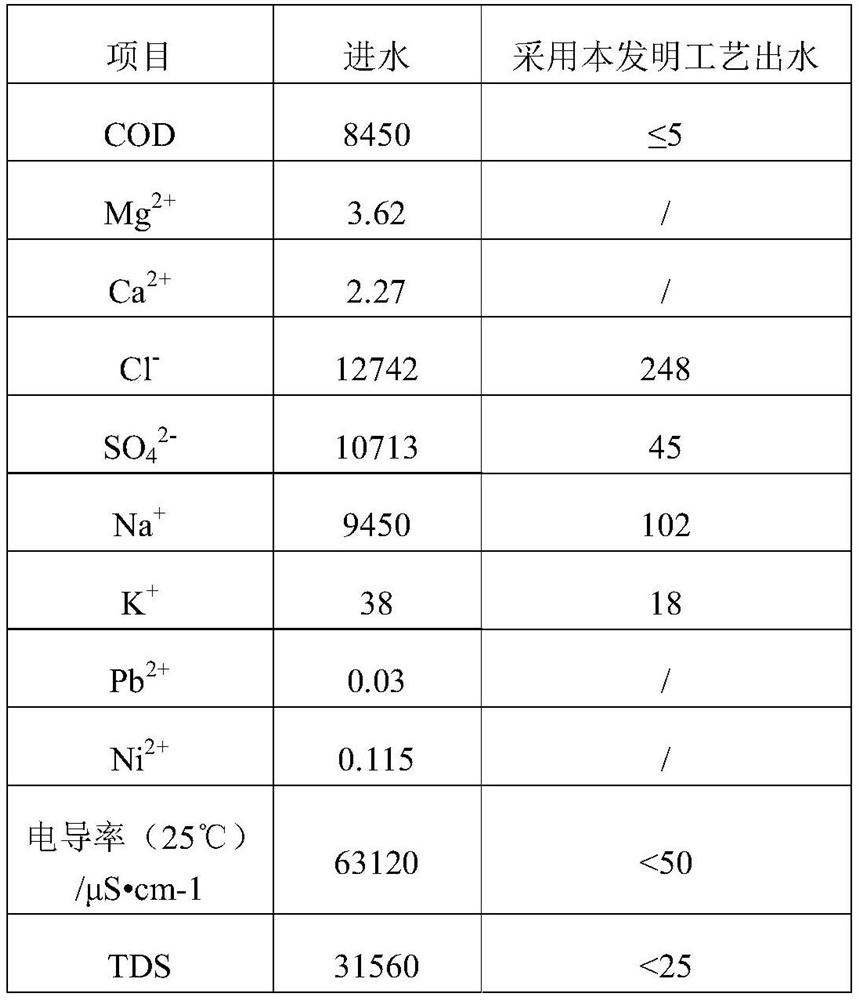

Embodiment 1

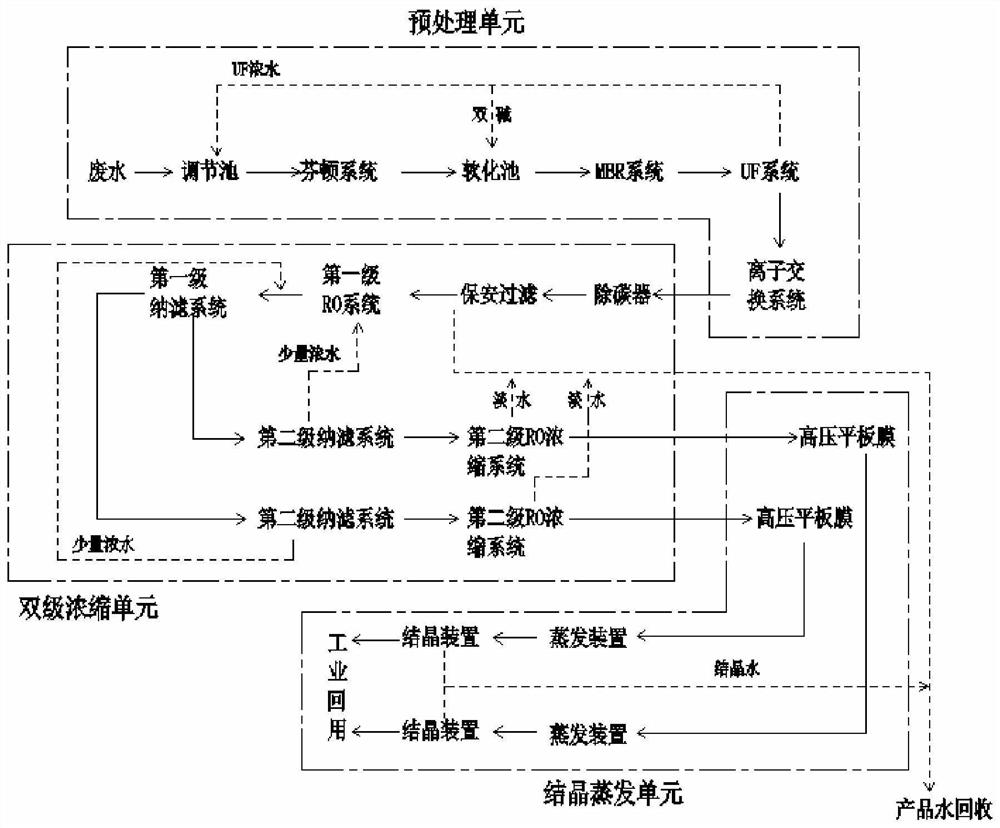

[0043] A zero-discharge system for recycling high-salt and high-COD wastewater, including:

[0044] High-efficiency pretreatment unit: the wastewater in the regulating tank enters the Fenton system to oxidize and remove some organic matter, enters the softening tank to remove hardness, and the produced water enters the MBR membrane bioreactor to further remove organic pollutants and turbidity through the action of microorganisms, and then enters the ultrafiltration system , after ion exchange;

[0045] Two-stage concentration unit: firstly remove carbon through the carbon remover, enter the first-stage RO system for concentration reduction through security filtration, and then obtain sodium chloride brine and sodium sulfate brine through two-stage nanofiltration system treatment, and then enter the second stage respectively The RO concentration system further concentrates and reduces the weight;

[0046] Evaporation and crystallization unit: After concentrated by high-pressur...

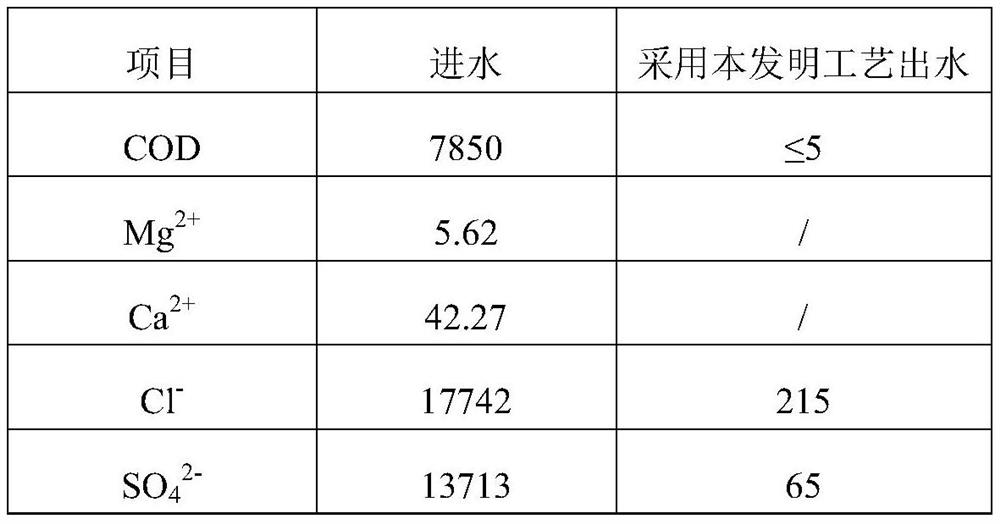

Embodiment 2

[0056] A zero-discharge system for recycling high-salt and high-COD wastewater, including:

[0057] High-efficiency pretreatment unit: the wastewater in the regulating tank enters the Fenton system to oxidize and remove some organic matter, enters the softening tank to remove hardness, and the produced water enters the MBR membrane bioreactor to further remove organic pollutants and turbidity through the action of microorganisms, and then enters the ultrafiltration system , after ion exchange;

[0058] Two-stage concentration unit: firstly remove carbon through the carbon remover, enter the first-stage RO system for concentration reduction through security filtration, and then obtain sodium chloride brine and sodium sulfate brine through two-stage nanofiltration system treatment, and then enter the second stage respectively The RO concentration system further concentrates and reduces the weight;

[0059] Evaporation and crystallization unit: After being concentrated by high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com