Treatment method for crystallization and salt separation of thermoelectric reverse osmosis concentrated water

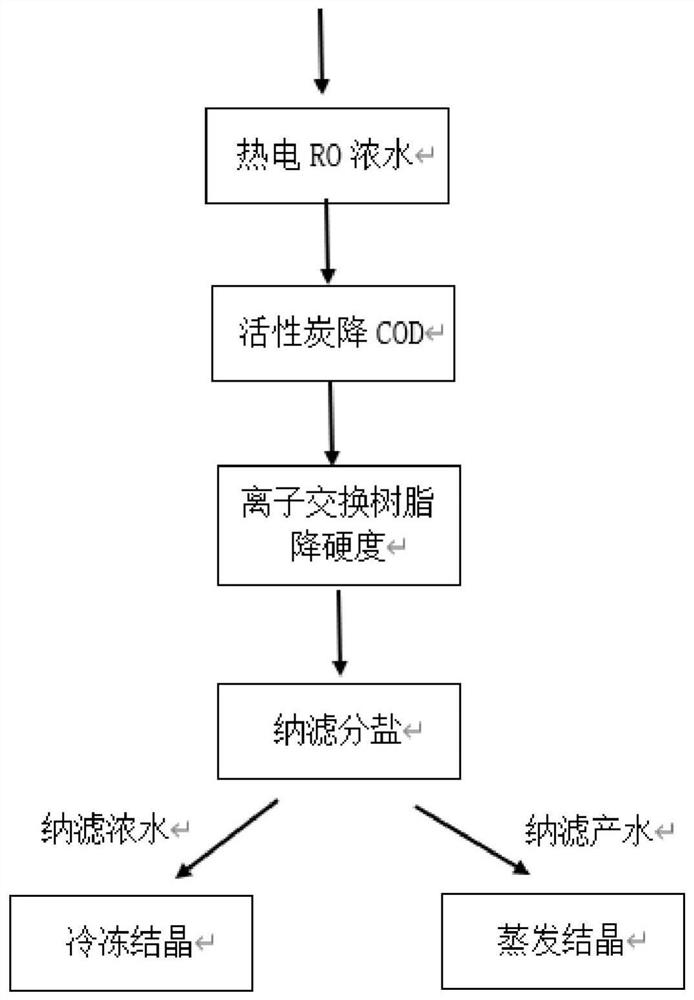

A technology for reverse osmosis concentrated water and a treatment method, which is applied in the field of thermoelectric reverse osmosis concentrated water crystallization and salt separation, can solve problems such as waste of resources, and achieve the effects of reducing the generation of hazardous waste, high salt separation efficiency, and promoting recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] After RO concentration in a thermal power plant, the concentrated water has a salt content of 11690mg / L, a COD content of 756mg / L, and a hardness of 1564mg / L. - : SO 4 2- = 0.97.

[0038] Its treatment process, concrete steps are as follows:

[0039] Adsorbed by the coconut shell activated carbon adsorption column, the flow rate of the feed liquid is 2BV, the iodine value of the coconut shell activated carbon is 950mg / g, and the COD content in the treated water is 26mg / L;

[0040] After dehardening by the ion exchange resin adsorption column, the hardness in the water is 17mg / L, and the flow rate of the feed liquid is 2BV;

[0041] The roll-type nanofiltration membrane separates salt, the pressure is controlled at 1.2Mpa, the water production rate is controlled at 89%, and the sulfate radical rejection rate is 98.85%. The purity of the obtained sodium chloride crystalline salt is 98.14%, reaching the standard of industrial qualified products; the yield is 46.97%;

...

Embodiment 2

[0044] After concentration of DTRO in the third phase of a thermal power plant, the concentrated water has a salt content of 42470mg / L, a COD content of 852mg / L, and a hardness of 2200mg / L. - : SO 4 2- = 0.93.

[0045] Its treatment process, concrete steps are as follows:

[0046] Use coconut shell activated carbon adsorption column for adsorption, the iodine value of coconut shell activated carbon is 950mg / g, the feed flow rate is controlled at 2BV, and the COD content in the water after adsorption is 42mg / L;

[0047] After dehardening by the ion exchange resin adsorption column, the hardness in the water is 36mg / L, and the flow rate of the feed liquid is 2BV;

[0048] The roll-type nanofiltration membrane separates salt, the pressure is controlled at 1.3Mpa, the water production rate is controlled at 93%, and the sulfate radical rejection rate is 98.77%. The purity of the obtained sodium chloride crystalline salt is 97.90%, reaching the standard of industrial qualified p...

Embodiment 3

[0051] The RO concentrated water of a power plant and a petrochemical electric dehydration mixed water sample, the salt content is 23240mg / L, the COD content is 509mg / L, the hardness is 1414mg / L, Cl - : SO 4 2- = 1.1.

[0052] Its treatment process, concrete steps are as follows:

[0053] Use coconut shell activated carbon adsorption column for adsorption, the iodine value of coconut shell activated carbon is 950mg / g, the feed flow rate is controlled at 2BV, and the COD content in water after adsorption is 29mg / L;

[0054] After dehardening by the ion exchange resin adsorption column, the hardness in the water is 31mg / L, and the flow rate of the feed liquid is 2BV;

[0055] The roll-type nanofiltration membrane separates salt, the pressure is controlled at 1.3Mpa, the water production rate is controlled at 94%, and the sulfate radical rejection rate is 98.89%. The purity of the obtained sodium chloride crystalline salt is 98.43%, reaching the standard of industrial qualifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com