High-toughness regenerated environment-friendly plastic and processing process thereof

A technology of environmentally friendly plastics and high toughness, applied in the field of recycled plastics, can solve the problems of affecting the transfer of soil substances and heat, the recovery rate is less than 10%, and the plastics cannot be degraded, so as to improve the relative molecular weight and small particle size , the effect of restoring toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

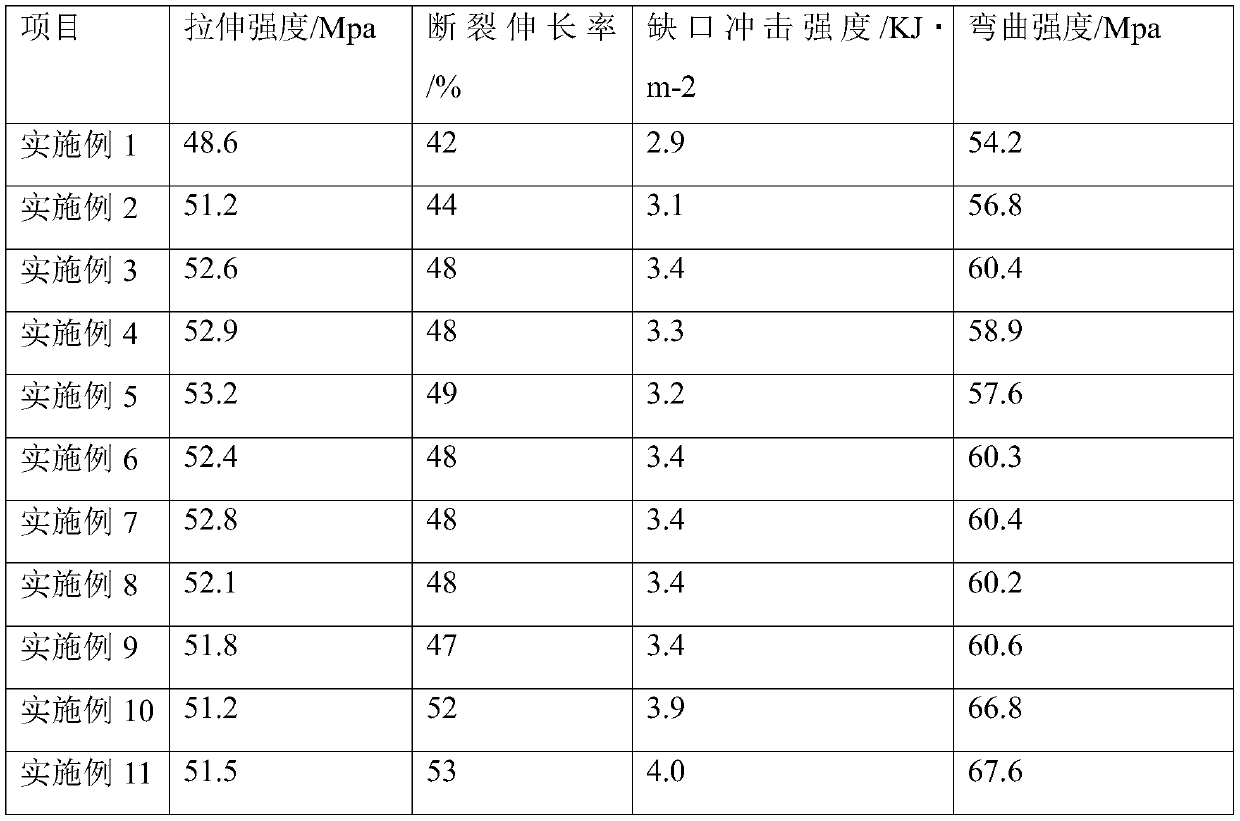

Examples

Embodiment 1

[0042] A kind of high-toughness regenerated environment-friendly plastics, raw materials include the following components by weight: 24 parts of waste and old PVC plastics, 22 parts of waste and old ABS plastics, 28 parts of PBT resin, 15 parts of inorganic nano fillers, 3 parts of dioctyl phthalate, toughened 4 parts of agent, 26 parts of styrene-ethylene-butadiene block copolymer, 5 parts of chain extender, 6 parts of polyethylene glycol, 2.2 parts of 2,6-di-tert-butyl-p-cresol;

[0043] Nano-sized zinc oxide is used as the inorganic nano-filler;

[0044] The toughening agent adopts hyperbranched polyamide ester;

[0045] The chain extender is 2,2'-(1,3-phenylene)-bisoxazoline;

[0046] A processing technology for high-toughness recycled environmentally friendly plastics, comprising the following steps:

[0047] S1: crushing, crushing waste PVC plastics and waste ABS plastics, and crushing them into strips with a length of 2cm;

[0048] S2: Cleaning, cleaning the broken was...

Embodiment 2

[0056] A kind of high-toughness regenerated environment-friendly plastics, raw materials include the following components by weight: 28 parts of waste and old PVC plastics, 30 parts of waste and old ABS plastics, 30 parts of PBT resin, 16 parts of inorganic nano fillers, 5 parts of dioctyl phthalate, toughening 6 parts of agent, 29 parts of styrene-ethylene-butadiene block copolymer, 8 parts of chain extender, 7 parts of polyethylene glycol, 2.4 parts of 2,6-di-tert-butyl-p-cresol;

[0057] Nano-sized zinc oxide is used as the inorganic nano-filler;

[0058] The toughening agent adopts hyperbranched polyamide ester;

[0059] The chain extender is 2,2'-(1,3-phenylene)-bisoxazoline;

[0060] A processing technology for high-toughness recycled environmentally friendly plastics, comprising the following steps:

[0061] S1: crushing, crushing waste PVC plastics and waste ABS plastics, and crushing them into strips with a length of 2cm;

[0062] S2: Cleaning, cleaning the broken ...

Embodiment 3

[0070] A kind of high-toughness regenerated environment-friendly plastics, raw materials include the following components by weight: 30 parts of waste and old PVC plastics, 34 parts of waste and old ABS plastics, 31 parts of PBT resin, 19 parts of inorganic nano fillers, 6 parts of dioctyl phthalate, toughening 7 parts of agent, 32 parts of styrene-ethylene-butadiene block copolymer, 11 parts of chain extender, 8 parts of polyethylene glycol, 2.5 parts of 2,6 di-tert-butyl-p-cresol; Zinc oxide;

[0071] The toughening agent adopts hyperbranched polyamide ester;

[0072] The chain extender is 2,2'-(1,3-phenylene)-bisoxazoline;

[0073] A processing technology for high-toughness recycled environmentally friendly plastics, comprising the following steps:

[0074] S1: crushing, crushing waste PVC plastics and waste ABS plastics, and crushing them into strips with a length of 2cm;

[0075] S2: Cleaning, cleaning the broken waste PVC plastics and waste ABS plastics, and removing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com