A kind of airgel flame retardant thermal insulation foam coating with graded pore microstructure and preparation method thereof

A flame retardant thermal insulation and aerogel technology, applied in the field of materials, can solve the problems of no adhesion, easy cracking, low mechanical modulus, etc., and achieves excellent construction performance, excellent thermal insulation and flame retardant performance, and low thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention provides a kind of preparation method of the airgel flame-retardant heat-retaining foam type coating that has hierarchical pore microstructure, comprising:

[0034] A) dispersing the thickener, curing agent, foaming agent and reinforcing fiber in a solvent to obtain a thickening solution;

[0035] B) mixing the thickening solution and the water-based resin to obtain a mixed solution;

[0036] C) Mixing the mixed solution and the airgel powder to obtain a creamy coating, which is an airgel flame-retardant thermal insulation foam coating with a hierarchical pore microstructure.

[0037] In the airgel flame-retardant thermal insulation foam coating with graded pore microstructure provided by the invention, thickener, curing agent, foaming agent and reinforcing fiber are dispersed in a solvent and stirred to obtain a thickened solution. The present invention does not limit the specific operation of the dispersing and stirring, as long as those skilled...

Embodiment 1

[0065] Disperse 4g sodium carboxymethylcellulose, 1.25g p-toluenesulfonic acid, and 1g glass fiber (Shanghai Sinopharm Group) in 100ml deionized water, stir overnight, then add 4g whey protein to obtain a high-viscosity light yellow solution, wait use.

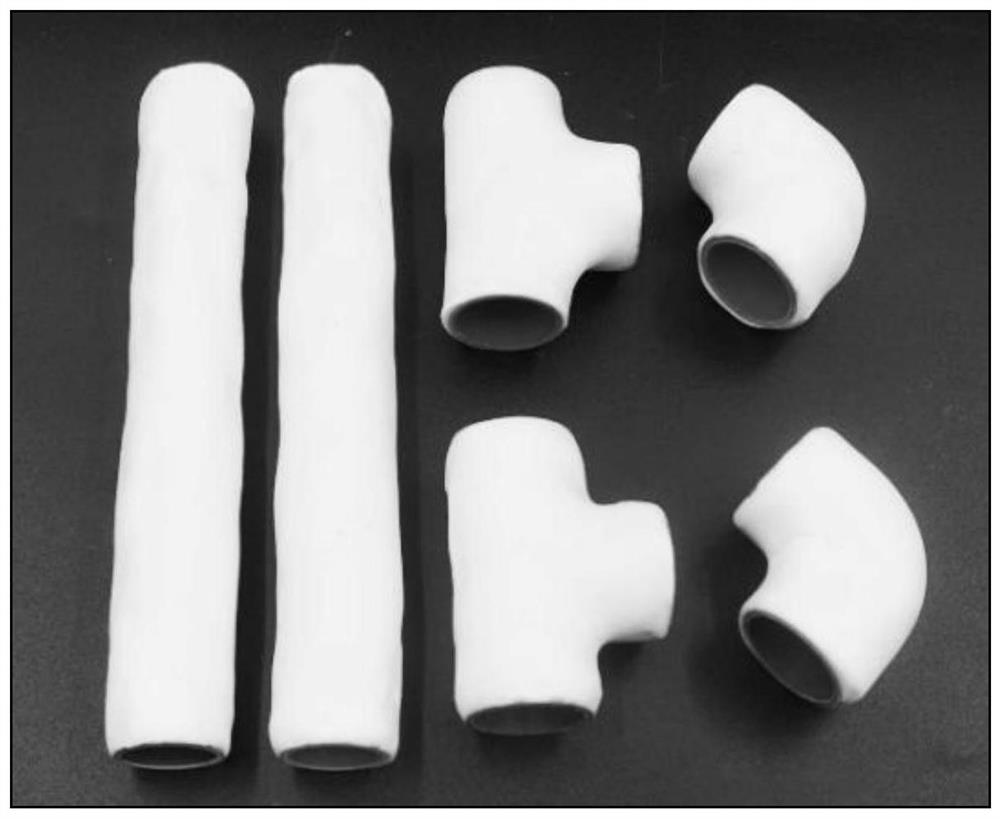

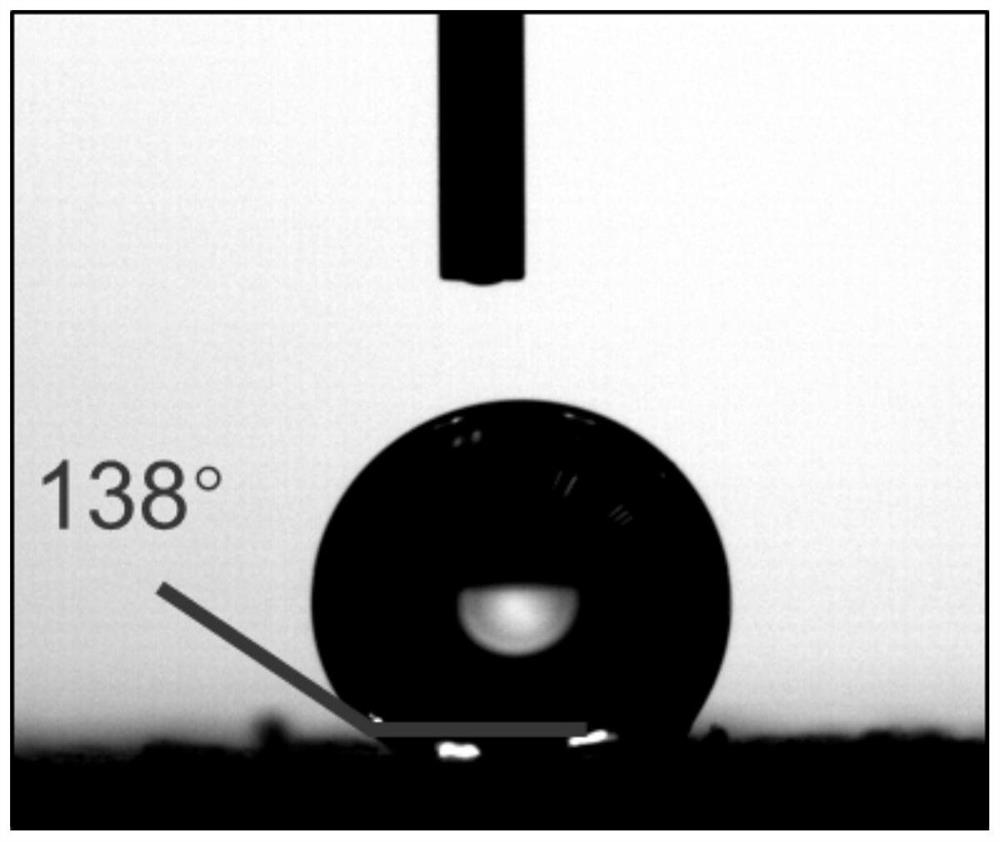

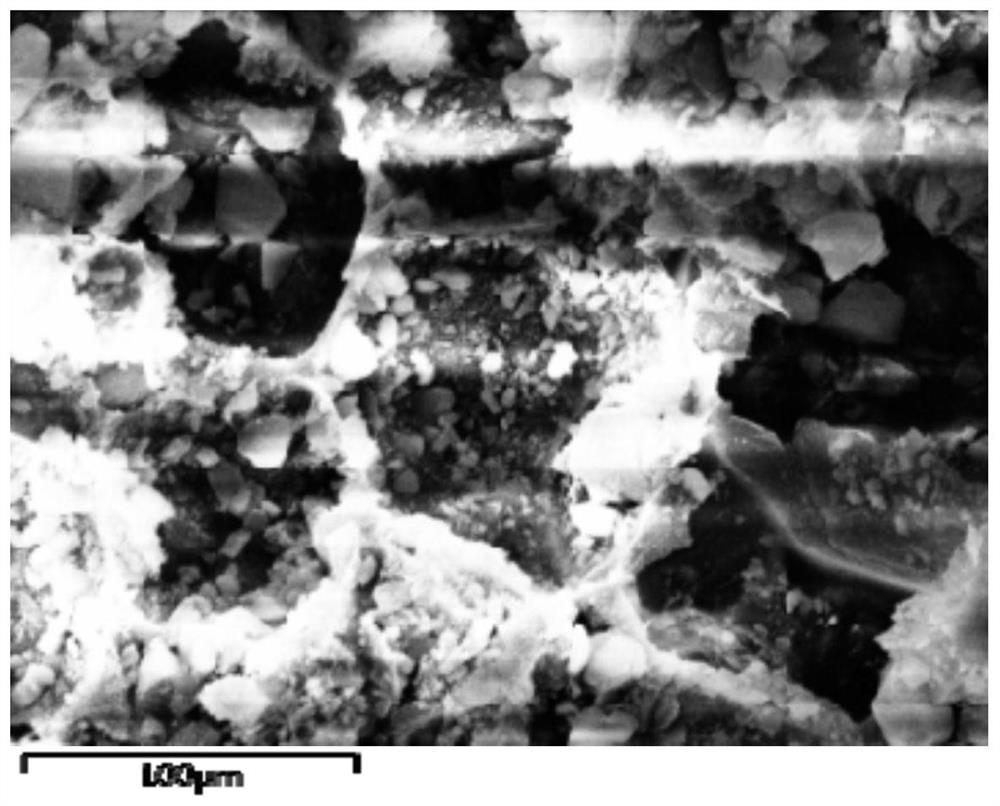

[0066] Take 20ml of the above solution into a beaker, add 10g of commercial melamine formaldehyde resin, 20g of commercial silica airgel powder, and stir for 10-20min to obtain a usable airgel foam coating. Coated on the surface of PVC plastic pipes and dried for 3 to 5 days to obtain the final coating product, such as figure 1 shown. The coating has obvious hydrophobicity, and its contact angle is 138°, such as figure 2 shown. The microstructure of the sample is a closed-cell foam structure with hierarchical pores, such as image 3 shown. After etching the silica airgel powder particles with NaOH, it can be seen that the macropores are overlapped by a three-dimensional network resin, such as Figure 4 and 5 shown.

...

Embodiment 2

[0069] Disperse 4g sodium carboxymethylcellulose, 1.25g p-toluenesulfonic acid, and 1g glass fiber (Shanghai Sinopharm Group) in 100ml deionized water, stir overnight, then add 4g whey protein to obtain a high-viscosity light yellow solution, wait use.

[0070] Take 20ml of the above solution into a beaker, add 10g of commercial melamine formaldehyde resin, add 5, 10, 15, and 20g of commercial silica airgel powder, and stir for 10-20min to obtain a usable airgel foam coating. After drying for 3 to 5 days, the final coating product is obtained, and the microstructure is as follows: Figure 8 shown. Depend on Figure 8 It can be seen that the airgel content affects the cell size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com