Wind turbine blade passivation treatment process

A wind power generator and passivation treatment technology, which is applied in heat treatment furnaces, heat treatment equipment, metal material coating technology, etc., can solve the problems of decreased mechanical properties and inability to maintain good work efficiency, etc., to improve the bonding force and density , Improving the composition of the crystal structure and improving the effect of film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

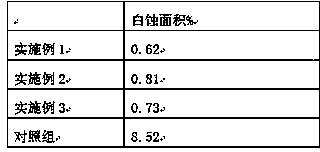

Examples

Embodiment 1

[0018] A passivation treatment process for wind turbine blades. After the wind turbine blades are cleaned, solution treatment is then performed, and the solution treated wind turbine blades are passivated with a polyether polyol-based passivation solution. get.

[0019] As a further technical solution, the cleaning is to use a mixed solution of sodium hydroxide and sodium carbonate to soak and clean the blades of the wind power generator in a water bath at 80°C for 10 minutes.

[0020] As a further technical solution, the sodium hydroxide mass fraction in the sodium hydroxide and sodium carbonate mixed solution is 10%, and the sodium carbonate mass fraction is 5%.

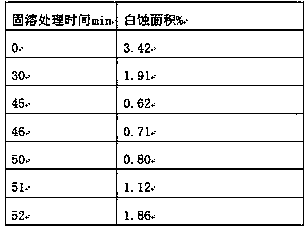

[0021] As a further technical solution, the solid solution treatment is as follows: adding the blades of the wind power generator into the resistance furnace, passing ammonia gas into the resistance furnace, removing the air in the resistance furnace, then heating to 1050°C, and keeping the temperature for 45-50min...

Embodiment 2

[0027] A passivation treatment process for wind turbine blades. After the wind turbine blades are cleaned, solution treatment is then performed, and the solution treated wind turbine blades are passivated with a polyether polyol-based passivation solution. get.

[0028] As a further technical solution, the cleaning is to use a mixed solution of sodium hydroxide and sodium carbonate to soak and clean the blades of the wind power generator in a water bath at 80°C for 10 minutes.

[0029] As a further technical solution, the sodium hydroxide mass fraction in the sodium hydroxide and sodium carbonate mixed solution is 10%, and the sodium carbonate mass fraction is 5%.

[0030] As a further technical solution, the solid solution treatment is as follows: adding the blades of the wind power generator into the resistance furnace, passing ammonia gas into the resistance furnace, removing the air in the resistance furnace, and then heating to 1060°C, holding the temperature for 50 minut...

Embodiment 3

[0036] A passivation treatment process for wind turbine blades. After the wind turbine blades are cleaned, solution treatment is then performed, and the solution treated wind turbine blades are passivated with a polyether polyol-based passivation solution. get.

[0037] As a further technical solution, the cleaning is to use a mixed solution of sodium hydroxide and sodium carbonate to soak and clean the blades of the wind power generator in a water bath at 80°C for 10 minutes.

[0038] As a further technical solution, the sodium hydroxide mass fraction in the sodium hydroxide and sodium carbonate mixed solution is 10%, and the sodium carbonate mass fraction is 5%.

[0039] As a further technical solution, the solid solution treatment is as follows: add the blades of the wind power generator into the resistance furnace, pass ammonia gas into the resistance furnace, remove the air in the resistance furnace, then heat to 1055°C, keep it warm for 46min, and then Carry out water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com