Preparation method of novel glass slag filter material with negatively charged modified surface

A negatively charged surface and filter material technology, which is applied in the fields of material science and adsorption science, can solve the problems of upper filter material loss, high production costs of water plants, and biofilm growth, so as to improve the filtration and adsorption effect and be economical. The effect of value and environmental significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

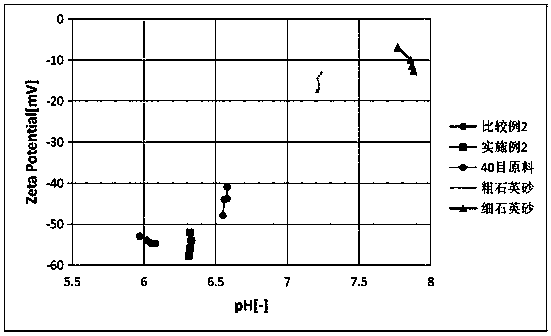

Examples

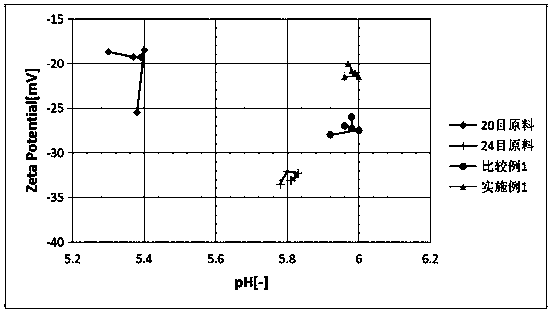

Embodiment 1

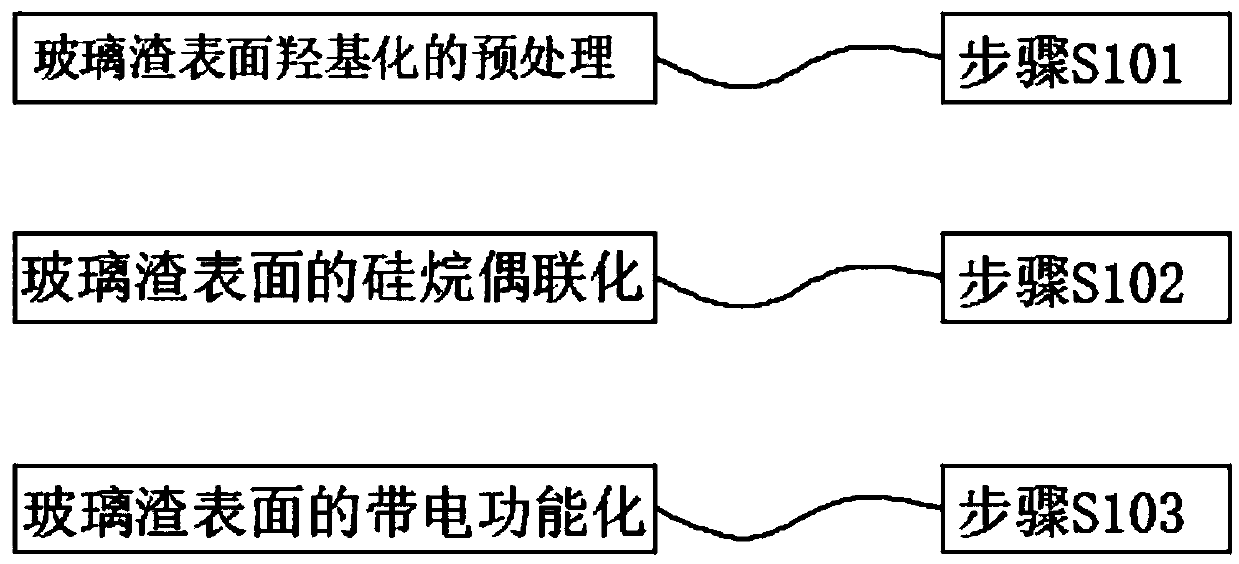

[0018] Step 1. Pretreatment of glass slag surface hydroxylation: a. Take 5 g of 24-mesh glass slag raw material, and use superior grade pure (GR) 99.8% ethanol to repeatedly clean the glass slag raw material for 6 times; b. Wash the cleaned glass Put the slag raw materials into beakers filled with deionized water, ethanol, and acetone in turn for 10 minutes; c. use nitrogen to completely dry the glass slag raw materials after ultrasonic cleaning; d. put the glass slag raw materials after nitrogen blowing into Add 100ml of "cannibal acid" solution (the volume ratio of concentrated sulfuric acid and hydrogen peroxide is 7:3), and then put it in a water bath at 95°C for 2h; After rinsing with sulfuric acid, put it in ethanol and save it for later use.

[0019] Step 2. Silane coupling on the surface of glass slag: a. Prepare a toluene solution of γ-methacryloxypropyltrimethoxysilane (MPS) (silane coupling agent) (the ratio of toluene to MPS: 8ml Toluene, 8mg MPS, and then use ace...

Embodiment 2

[0022] Step 1. Pretreatment of glass slag surface hydroxylation: a. Take 5 g of 40-mesh glass slag raw material, and use superior grade pure (GR) 99.8% ethanol to repeatedly clean the glass slag raw material for 6 times; b. Wash the cleaned glass Put the slag raw materials into beakers filled with deionized water, ethanol, and acetone in turn for 10 minutes; c. use nitrogen to completely dry the glass slag raw materials after ultrasonic cleaning; d. put the glass slag raw materials after nitrogen blowing into Add 100ml of "cannibal acid" solution (the volume ratio of concentrated sulfuric acid and hydrogen peroxide is 7:3), and then put it in a water bath at 95°C for 2h; After rinsing with sulfuric acid, put it in ethanol and save it for later use.

[0023] Step 2. Silane coupling on the surface of glass slag: a. Prepare a toluene solution of γ-methacryloxypropyltrimethoxysilane (MPS) (silane coupling agent) (the ratio of toluene to MPS: 8ml Toluene, 8mg MPS, and then use ace...

Embodiment 3

[0026]Take 24 mesh glass slag raw materials, 24 mesh modified new glass slag filter materials with negative charges on the surface, and ordinary quartz sand, each about 30g, and place them in the filter column. The thickness of the filter layer is about 13cm. The incoming river water was subjected to filtration experiments, and the raw water before filtration and the effluent after filtration were both tested for turbidity with a turbidity meter. The results are shown in Table 1:

[0027] Table I:

[0028]

[0029] In order to illustrate the effect of the present invention, the inventor provides comparative experiments as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com