Preparation method and application of green synthesis novel iron-carbon material

A green synthesis and new technology, applied in chemical instruments and methods, metal processing equipment, transportation and packaging, etc., can solve the problems of reduced activity, degradation rate, limited preservation and service life, etc., to achieve strong antioxidant capacity, prevent The effect of agglomeration and prevention of deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

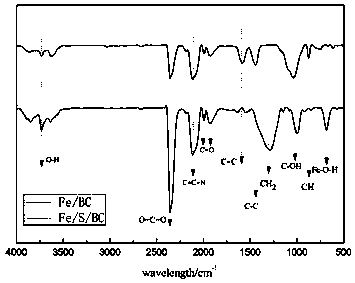

Method used

Image

Examples

Embodiment 1

[0027] (1) Pretreatment of biomass materials: Wash the duckweed with deionized water, dry it at 60-80°C, crush it to 20-50mm with a grinder, and set it aside.

[0028] (2) Preparation of biochar: The biomass material in step (1) was placed in a porcelain boat and placed in a tube furnace under N 2 Pyrolysis was carried out in the atmosphere, the initial temperature was 40°C, and the temperature was raised to 600°C at a heating rate of 5°C / min, and kept for 2 hours to obtain biochar, which was ground and passed through a 100-mesh sieve for later use.

[0029] (3) Preparation of red clover extract: weigh 6g of red clover powder, place it in a 250mL round bottom flask, add a certain amount of mixture of absolute ethanol and deionized water (volume ratio V 水 :V 乙醇 =4:6), placed in an ultrasonic cleaner, refluxed in a water bath at 60°C for extraction, and transferred to a sample bottle after centrifugal filtration.

[0030] (4) Preparation of iron salt solution: 4.47gFeSO 4 ﹒ ...

Embodiment 2

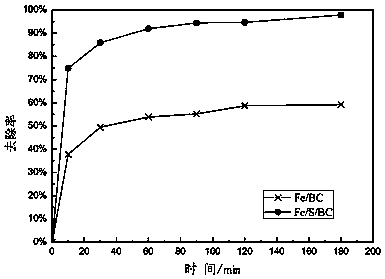

[0036] The new iron-carbon material prepared was applied to the removal experiment of Cr(Ⅵ) in water. Take 0.10 g of the new iron-carbon material and add it to 100 mL of Cr(VI) solution with a concentration of 50 mg / L, put it into a constant temperature shaking box and shake it at room temperature at a speed of 100 r / min for 3 hours. In the middle, samples were taken at 10 min, 30 min, 60 min, 90 min, 120 min and 180 min, filtered with a 0.45 μm filter, and the concentration of Cr(VI) in the sample was measured by ultraviolet spectrophotometry, and the new iron-carbon material was obtained. Cr(Ⅵ) degradation curve.

Embodiment 3

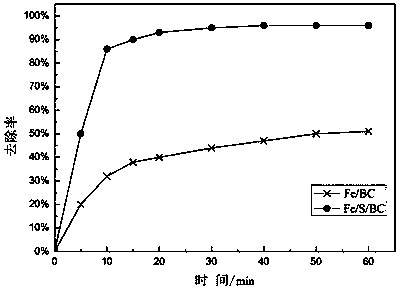

[0038] The new iron-carbon material prepared was applied to the removal experiment of methylene blue in water. Take 0.05g of the new iron-carbon material and add it to 60mL of methylene blue solution with a concentration of 0.1g / L, put it into a constant temperature shaking box and shake it at room temperature at a speed of 100r / min for 1h. Samples were taken at 10 min and 30 min in the middle, filtered with a 0.45 μm filter, and the absorbance was measured at a wavelength of 664 nm with a spectrophotometer to obtain the degradation curve of the new iron-carbon material to methylene blue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com