Composite powder for open arc surfacing welding austenitic high chromium alloy and application method thereof

A high-chromium alloy and austenite welding technology is applied in the field of open-arc surfacing welding of composite powders of austenitic high-chromium alloys, which can solve the problems of uneconomical, high cost, and high price, and achieve low cost and good toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

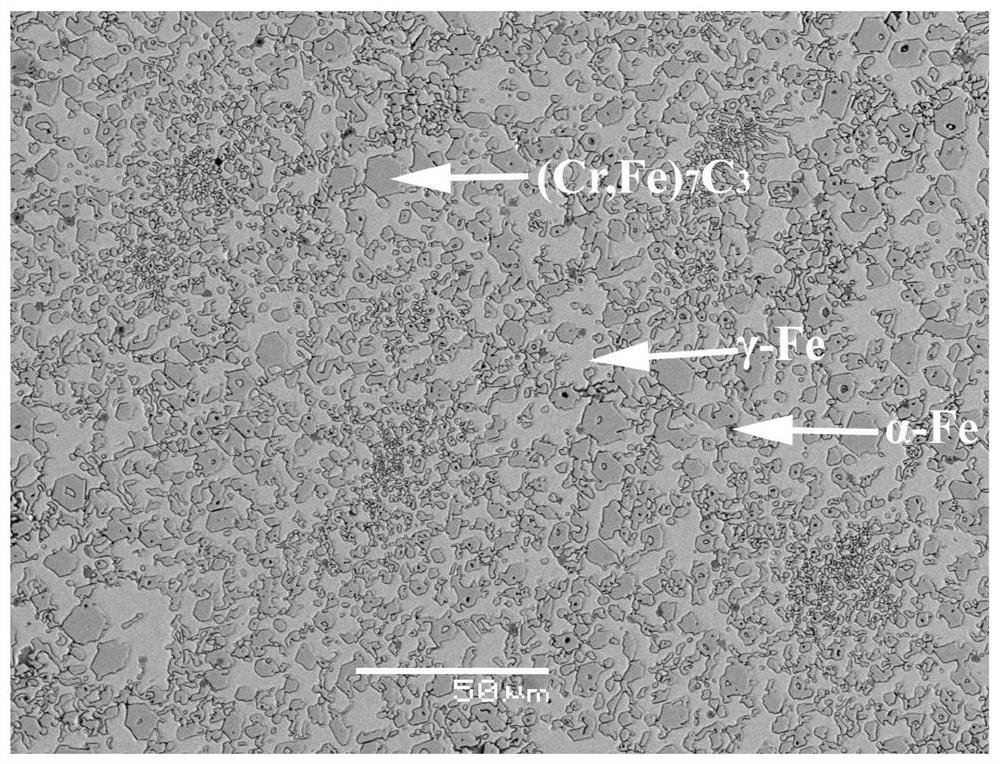

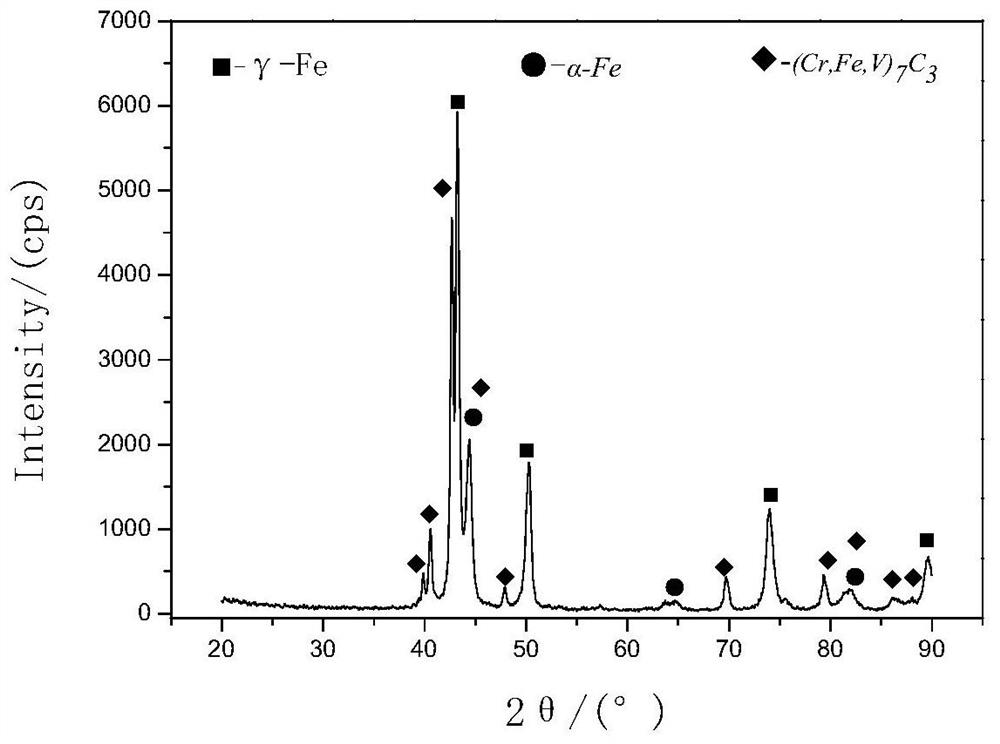

Embodiment 1

[0040]Before weighing, the powder components such as high-carbon ferrochromium, ferro-vanadium, ferrosilicon, flake graphite and reduced iron powder are passed through a 60-mesh sieve, and aluminum powder is passed through a 300-mesh sieve. The composition ratio (weight percentage) of the powder components contained in the composite powder particles is: high-carbon ferrochrome 75%, ferro-vanadium 10%, ferrosilicon 2%, flake graphite 6%, aluminum powder 0.5%, reduced iron powder 6.5 %. Weigh high-carbon ferrochromium, ferro-vanadium, ferrosilicon, flake graphite, aluminum powder and reduced iron powder according to the requirements of the powder components contained in the above-mentioned composite powder, and then weigh all the above-mentioned powders The components are put into the same container and stirred thoroughly to make them evenly mixed to form a mixed powder.

[0041]Next, add 5ml of sodium silicate type water glass with Baume degree 40 and modulus 3.0 to the above mixed powd...

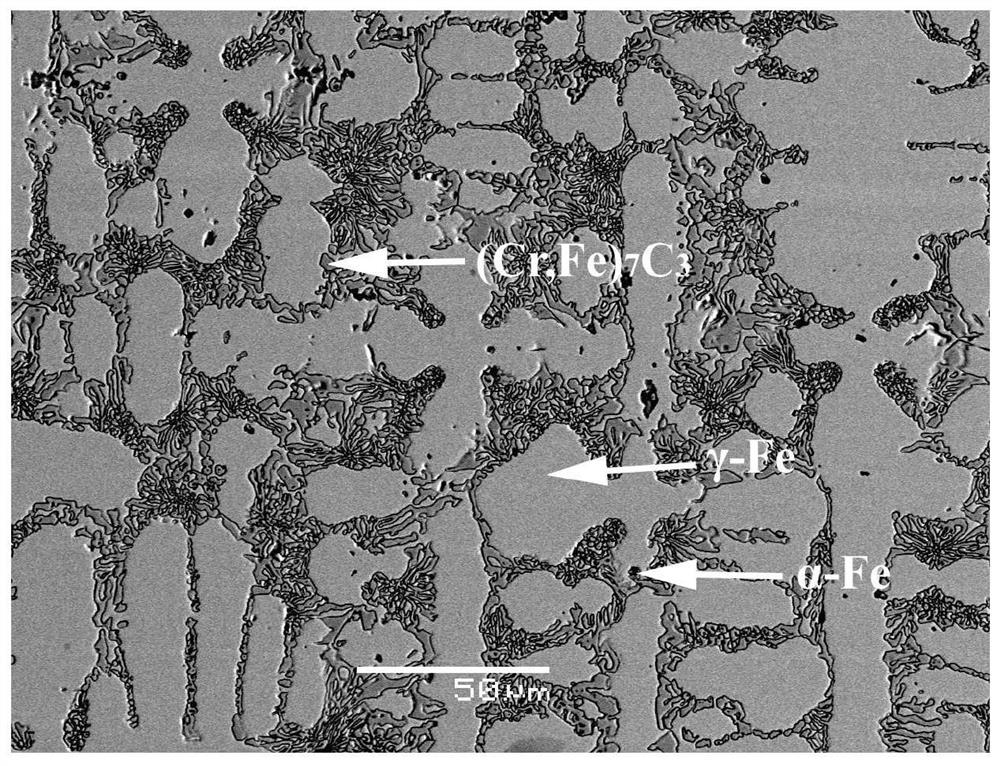

Embodiment 2

[0053]Before weighing, the powder components such as high-carbon ferrochromium, ferro-vanadium, ferrosilicon, flake graphite and reduced iron powder are passed through a 60-mesh sieve, and aluminum powder is passed through a 300-mesh sieve. The composition ratio (weight percentage) of the powder components contained in the composite powder is: high carbon ferrochrome 70%, ferro-vanadium 8.5%, ferrosilicon 3%, flake graphite 6.5%, aluminum powder 0.75%, reduced iron powder 11.25 %. Weigh high-carbon ferrochromium, ferro-vanadium, ferrosilicon, flake graphite, aluminum powder, and reduced iron powder according to the ratio requirements of the powder components contained in the above composite powder particles, and then weigh all the above-mentioned powders The components are put into the same container and stirred thoroughly to make them evenly mixed to form a mixed powder.

[0054]Next, add 5ml of sodium silicate type water glass with Baume 30 and modulus 3.3 to the above mixed powder e...

Embodiment 3

[0059]Before weighing, the powder components such as high-carbon ferrochromium, ferro-vanadium, ferrosilicon, flake graphite and reduced iron powder are passed through a 60-mesh sieve, and aluminum powder is passed through a 300-mesh sieve. The composition ratio (weight percentage) of the powder components contained in the composite powder is: 73% high carbon ferrochrome, 8% ferro-vanadium, 1% ferrosilicon, 5.5% flake graphite, 1.0% aluminum powder, and 11.5 reduced iron powder %. Weigh high-carbon ferrochromium, ferro-vanadium, ferrosilicon, flake graphite, aluminum powder and reduced iron powder according to the requirements of the proportion of powder components contained in the above composite powder, and then weigh all the above-mentioned powder components Place them in the same container and stir thoroughly to make them evenly mixed to form a mixed powder.

[0060]Next, add 5ml of sodium silicate type water glass with Baume degree 35 and modulus 3.3 to each of the above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com