Method for treating crystalline residual salt of salt-containing organic wastewater and application of method

A technology of organic wastewater and treatment methods, applied to the removal of solid waste, etc., can solve problems such as high toxicity, complex components, and high impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

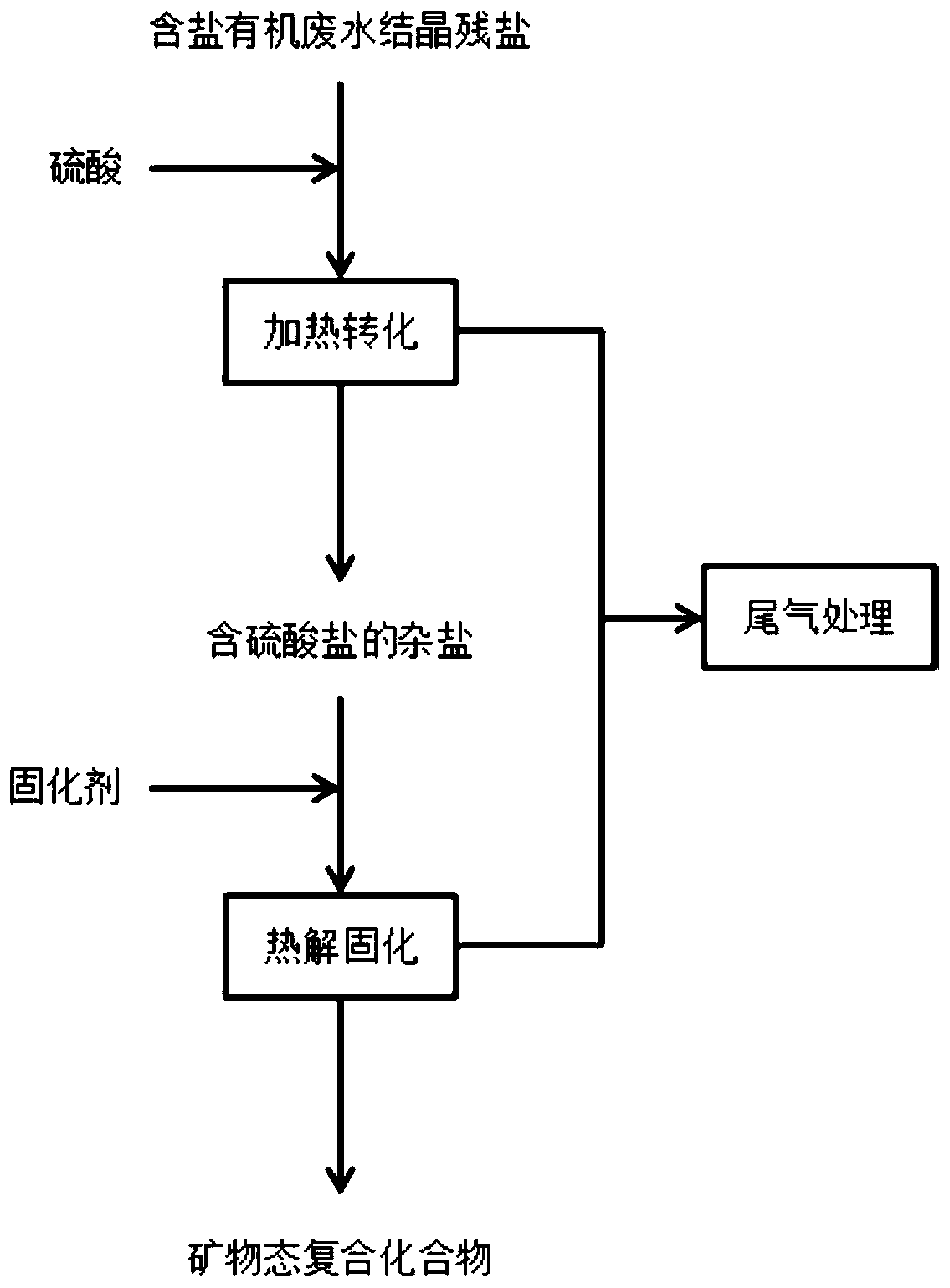

Method used

Image

Examples

Embodiment 1

[0050] (1) Mix the crystalline residual salt of salt-containing organic wastewater with twice the mass fraction of 95% sulfuric acid, heat to 500° C., and react for 3 hours to obtain the miscellaneous salt containing sulfate;

[0051] (2) Mix the sulfate-containing miscellaneous salt obtained in step (1) with 4 times the mixed curing agent of kaolin: silica sand at a ratio of 1:2, grind to 100 mesh, and then roast at 1200°C for 2 hours to obtain water-insoluble mineral complex compounds.

[0052] The crystalline residual salt used in this example is from a pesticide factory in Weifang, Shandong Province, which is the residual salt evaporated from the concentrated mother liquor after fractional crystallization of the waste salt. The inorganic salts in the residual salt are mainly sodium chloride and sodium sulfate, and the TOC content in the residual salt is 8000mg / kg, calcium 620mg / kg, magnesium 73mg / kg, aluminum 95mg / kg, iron 40mg / kg, chromium 20mg / kg. The mineral complex c...

Embodiment 2

[0054] (1) Mix the crystalline residual salt of salt-containing organic wastewater with 1 times of sulfuric acid with a mass fraction of 98%, heat to 100° C., and react for 1 hour to obtain a sulfate-containing miscellaneous salt;

[0055] (2) Mix the sulphate-containing miscellaneous salt obtained in step (1) with 3 times red mud: fly ash mixed solidifying agent at a ratio of 1:3, grind to 20 mesh, and then roast at 700°C for 1 hour, A water-insoluble mineral complex compound is obtained.

[0056] The crystalline residual salt used in this example is from a pesticide factory in Weifang, Shandong Province, which is the residual salt evaporated from the concentrated mother liquor after fractional crystallization of the waste salt. The inorganic salts in the residual salt are mainly sodium chloride and sodium sulfate, and the TOC content in the residual salt is 8000mg / kg, calcium 620mg / kg, magnesium 73mg / kg, aluminum 95mg / kg, iron 40mg / kg, chromium 20mg / kg. The mineral complex...

Embodiment 3

[0058] (1) Mix the crystalline residual salt of salt-containing organic wastewater with 2.5 times of sulfuric acid with a mass fraction of 95%, heat to 400° C., and react for 3 hours to obtain a sulfate-containing miscellaneous salt;

[0059] (2) Mix the sulfate-containing miscellaneous salt obtained in step (1) with 4 times of fly ash, grind to 50 mesh, and then roast at 1150° C. for 2 hours to obtain a water-insoluble mineral complex compound.

[0060] The crystalline residual salt used in this example comes from the residual salt evaporated from the concentrated mother liquor after the waste salt of a certain chemical plant in Hebei is separated and crystallized. The inorganic salts in the residual salt are mainly potassium chloride and potassium sulfate, and the TOC content in the residual salt is 6500mg / kg, calcium 400mg / kg, magnesium 80mg / kg, aluminum 60mg / kg, iron 76mg / kg, chromium 26mg / kg. The mineral complex compound obtained by making the residual salt harmless has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com