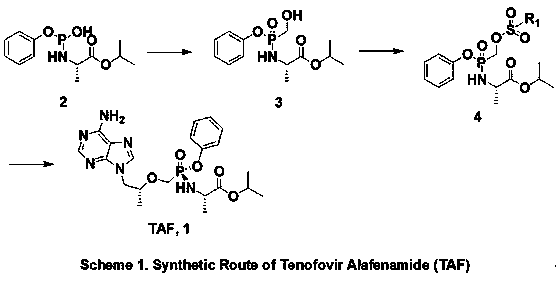

Preparation method of tenofovir alafenamide (TAF) synthesized through three-step method

A technology of tenofovir alafenamide and ethylphosphonamide, which is applied in the field of preparation of tenofovir alafenamide by three-step method, can solve the problems of difficult industrial production, large environmental pollution and high preparation cost , to achieve the effect of simple method, environmental friendliness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020]The preparation method of tenofovir alafenamide: phenoxy N-(1-isopropoxyformyl) ethyl phosphoramidite (271.25 g, 1.00 mol), paraformaldehyde (36.80 g, 1.20 mol ) and toluene (0.80 L) were placed in a three-necked flask, and triethylamine (50.50 g, 0.50 mol) was slowly added dropwise at 25 °C. After the addition was completed, the temperature was raised to 90 °C and stirred for 2 h. Reflux for 3 h. Cooling, washing with water, and drying to obtain product 3: 2-(2,3,4,5-tetrafluorophenyl)formyl-3-(1-hydroxy-1-phenylmethyl)aminoethyl acrylate Toluene solution. Cool the toluene solution of product 3 to 5 °C, slowly add triethylamine (50.50 g, 0.50 mol) dropwise, and continue to drop p-toluenesulfonyl chloride (190.65 g, 1.00 mol) at this temperature after the dropwise addition, and wait After the dropwise addition, the temperature was slowly raised to room temperature and stirred for 2 h. Wash with water and dry to obtain product 4: toluene solution of p-toluenesulfonylox...

Embodiment 2

[0022] The preparation method of tenofovir alafenamide: phenoxy N-(1-isopropoxyformyl) ethyl phosphoramidite (271.25 g, 1.00 mol), paraformaldehyde (36.80 g, 1.20 mol ) and anisole (0.80 L) were placed in a three-necked flask, and pyridine (39.55 g, 0.50 mol) was slowly added dropwise at 25 °C. After the addition was completed, the temperature was raised to 90 °C and stirred for 2 h. Reflux for 3 h. Cooling, washing with water, and drying to obtain product 3: 2-(2,3,4,5-tetrafluorophenyl)formyl-3-(1-hydroxy-1-phenylmethyl)aminoethyl acrylate Anisole solution. Cool the anisole solution of product 3 to 5°C, slowly add pyridine (39.55 g, 0.50 mol) dropwise, and continue to add benzenesulfonyl chloride (176.65 g, 1.00 mol) dropwise at this temperature slowly after the dropwise addition, and wait until the dropwise After the addition was completed, the temperature was slowly raised to room temperature and stirred for 2 h. Washed with water and dried to obtain product 4: an aniso...

Embodiment 3

[0024] The preparation method of tenofovir alafenamide: phenoxy N-(1-isopropoxyformyl) ethyl phosphoramidite (271.25 g, 1.00 mol), formaldehyde (36.80 g, 1.20 mol) and 1,2-Dichloroethane (0.80 L) was placed in a three-necked flask, and N-methylimidazole (41.05 g, 0.50 mol) was slowly added dropwise at 25 °C. After the addition was completed, the temperature was raised to 90 °C and stirred for 2 h. The reaction The liquid was clear, and the temperature was slowly raised to reflux for 3 h. Cooling, washing with water, and drying to obtain product 3: 2-(2,3,4,5-tetrafluorophenyl)formyl-3-(1-hydroxy-1-phenylmethyl)aminoethyl acrylate 1,2-dichloroethane solution. Cool the 1,2-dichloroethane solution of product 3 to 5 °C, slowly add N-methylimidazole (41.05 g, 0.50 mol) dropwise, and continue to drop methanesulfonyl chloride ( 114.55 g, 1.00 mol), after the dropwise addition was completed, the temperature was slowly raised to room temperature, and stirred for 2 h. Wash with water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com