Preparation technology, products and application of inorganic strong acid ammonium salt modified cocoanut active carbon for removing formaldehyde in air at normal temperature

A technology of coconut shell activated carbon and acid ammonium salt, applied in gas treatment, other chemical processes, chemical instruments and methods, etc., can solve the problems of easy deactivation of active components, high cost, secondary pollution, etc., and achieve easy industrial production , low price, the effect of removing formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

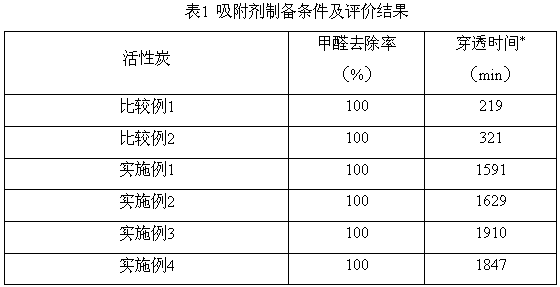

Embodiment 1

[0039] Take 60ml of coconut shell activated carbon and vacuum heat treatment at 125°C in an oven for 12 hours; impregnate the vacuum heat-treated coconut shell activated carbon with 60ml of 0.2mol / L hydrochloric acid solution for 12 hours, filter and remove excess acid; spread coconut shell activated carbon in an oven at 100°C Dry for 12 hours; the dried coconut shell activated carbon is impregnated with equal volume of 30% hydrogen peroxide, and dried in an oven at 90°C for 12 hours; the activated carbon after oxidation treatment is immersed in 60ml of 0.15M ammonium sulfate solution for 16 hours, and the excess salt solution is removed by filtration; finally The coconut shell activated carbon is paved and dried in an oven at 80° C. for 24 hours, and a kind of inorganic strong acid ammonium salt modified coconut shell activated carbon is obtained after cooling. The activated carbon was evaluated by the aforementioned evaluation device, the formaldehyde removal rate was 100%, a...

Embodiment 2

[0041] Take 60ml of coconut shell activated carbon and vacuum heat treatment at 150°C in an oven for 12 hours; impregnate the vacuum heat-treated coconut shell activated carbon with 60ml of 0.5mol / L hydrochloric acid solution for 12 hours, and filter to remove excess acid; spread the coconut shell activated carbon in an oven at 80°C Dry for 24 hours; the dried coconut shell activated carbon is impregnated with equal volume of 30% hydrogen peroxide, and dried in an oven at 90°C for 12 hours; the activated carbon after oxidation treatment is immersed in 60ml 0.20M ammonium nitrate solution for 16 hours, and the excess salt solution is removed by filtration; The coconut shell activated carbon is paved and dried in an oven at 60°C for 48 hours, and after cooling, an inorganic strong acid ammonium salt modified coconut shell activated carbon is obtained. The activated carbon was evaluated by the aforementioned evaluation device, the formaldehyde removal rate was 100%, and the breakt...

Embodiment 3

[0043]Take 60ml of coconut shell activated carbon and vacuum heat treatment at 125°C in an oven for 12 hours; impregnate the vacuum heat-treated coconut shell activated carbon with 60ml of 0.3mol / L hydrochloric acid solution for 12 hours, and filter to remove excess acid; spread the coconut shell activated carbon in an oven at 100°C Dry for 12 hours; impregnate the dried coconut shell activated carbon with equal volume of 30% hydrogen peroxide, and dry in an oven at 90°C for 12 hours; impregnate the oxidized activated carbon in 60ml of 0.25M ammonium sulfate solution for 16 hours, and filter to remove excess salt solution; The coconut shell activated carbon is paved and dried in an oven at 60°C for 24 hours, and a kind of inorganic strong acid ammonium salt modified coconut shell activated carbon is obtained after cooling. The activated carbon was evaluated by the aforementioned evaluation device, the formaldehyde removal rate was 100%, and the breakthrough time was 1910min. Se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com