Modification method of activated carbon fiber filter screen for removing high-concentration formaldehyde in air, and product and application thereof

A technology of activated carbon fiber and filter screen, which is applied in the field of activated carbon fiber filter screen modification, which can solve the problems of high cost of use and insufficient service life, etc., and achieve the effects of increased unit adsorption capacity, long penetration time, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

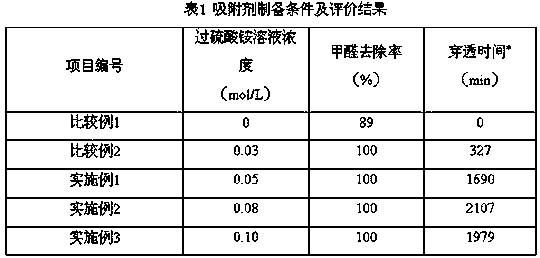

Embodiment 1

[0033] An activated carbon fiber filter screen for removing higher concentrations of formaldehyde in the air, using ozone and ammonium persulfate to treat the activated carbon fiber filter screen as a formaldehyde adsorbent, prepared according to the following steps:

[0034] Step 1 Activated carbon fiber filter pretreatment: put 10ml of activated carbon fiber filter in an oven for heat treatment at 200°C for 4 hours;

[0035] Step 2. Ozone surface strong oxidation treatment of activated carbon fiber filter: add it to an ozone oxidation device equipped with 50ml deionized water, control the flow rate to 500ml / min, and pass through 100mg / L ozone for 0.5h;

[0036] Step 3 drying treatment: flatten the activated carbon fiber filter screen after the ozone treatment in step 2, and dry it in an oven at 110°C for 12 hours;

[0037] Step 4 ammonium persulfate modification treatment: the activated carbon fiber filter screen dried in step 3 is impregnated with 0.05mol / L ammonium persulf...

Embodiment 2

[0040] An activated carbon fiber filter screen for removing higher concentration formaldehyde in the air is prepared according to the following steps:

[0041] Step 1 Activated carbon fiber filter pretreatment: put 10ml of activated carbon fiber filter in an oven for heat treatment at 200°C for 5 hours;

[0042] Step 2 Ozone surface strong oxidation treatment of activated carbon fiber filter screen: add the activated carbon fiber filter screen pretreated in step 1 into the ozone oxidation device equipped with 50ml deionized water, control the flow rate to 500ml / min, and pass through 100mg / L ozone treatment 0.5h;

[0043] Step 3 drying treatment: flatten the activated carbon fiber filter screen after the ozone treatment in step 2, and dry it in an oven at 110°C for 12 hours;

[0044] Step 4 ammonium persulfate modification treatment: the activated carbon fiber filter screen dried in step 3 is impregnated with 0.08mol / L ammonium persulfate solution at 60°C for 24 hours; The ac...

Embodiment 3

[0046] An activated carbon fiber filter screen for removing higher concentration formaldehyde in the air is prepared according to the following steps:

[0047] Step 1 Activated carbon fiber filter pretreatment: put 10ml of activated carbon fiber filter in an oven for heat treatment at 200°C for 8 hours;

[0048] Step 2 Ozone surface strong oxidation treatment of activated carbon fiber filter screen: add the activated carbon fiber filter screen pretreated in step 1 into the ozone oxidation device equipped with 50ml deionized water, control the flow rate to 500ml / min, and pass through 100mg / L ozone treatment 0.5h;

[0049] Step 3 drying treatment: flatten the activated carbon fiber filter screen after the ozone treatment in step 2, and dry it in an oven at 110°C for 12 hours;

[0050] Step 4 ammonium persulfate modification treatment: the activated carbon fiber filter screen dried in step 3 is impregnated with 0.10 mol / L ammonium persulfate solution at 60°C for 12 hours for modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com