Welded part precoated with soft solder layer(s) and preparation method for welded part

A technology of soft solder and weldment, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as unfavorable positioning, unfavorable welding quality, and inconvenient use by customers, achieve good welding quality, reduce welding void rate, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

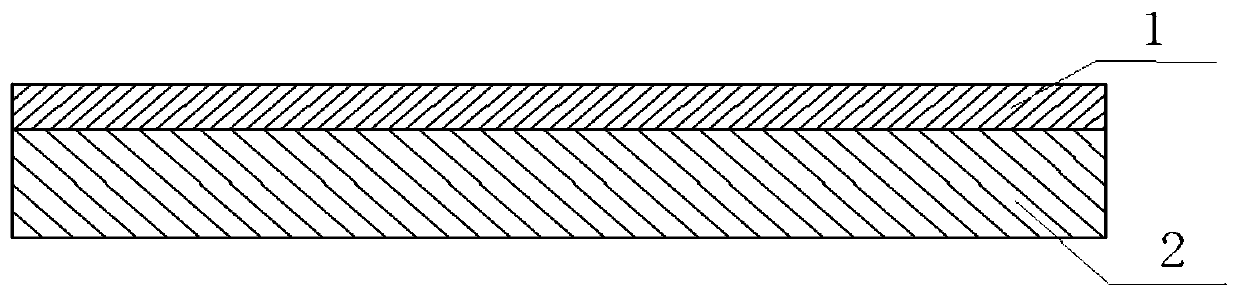

[0047] Figure 1a The surface material of the part to be welded is copper, the composition of the soft solder layer is Pb92.5Sn5Ag2.5 in lead-based solder, and the thickness of the soft solder layer is 0.06mm. The preparation method comprises the following steps:

[0048] Step 1) Prepare the configured Pb92.5Sn5Ag2.5 soft solder into a strip of required thickness by calendering;

[0049] Step 2) cutting the strip in step 1) into a solder sheet having a size equivalent to the surface of the welded piece, and coating the solder sheet with a rosin-type flux suitable for copper welding;

[0050] Step 3) Assembling the welding sheet in step 2) and the piece to be welded;

[0051] Step 4) Put the solder piece assembled in step 3) and the workpiece to be welded through the hot pressing welding process: preheat at 220°C for 30 seconds, and then contact the assembled solder piece with a graphite hot pressing head at a temperature of 400°C and the welded piece, and keep it for 20 seconds...

Embodiment 2

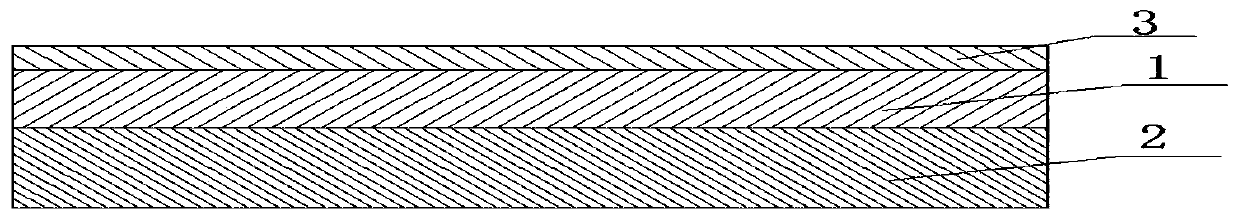

[0053] Figure 1b The surface material of the part to be welded is nickel, the composition of the soft solder layer is Sn96.5Ag3Cu0.5 in tin-based solder, and the thickness of the soft solder layer is 0.1mm. The preparation method comprises the following steps:

[0054] Step 1) Prepare the configured Sn96.5Ag3Cu0.5 soft solder into a strip of required thickness by calendering;

[0055] Step 2) cutting the material strip in step 1) into a solder sheet having a size equivalent to the surface size of the welded part, and coating the rosin-type flux suitable for welding the nickel-plated parts on the solder sheet;

[0056] Step 3) Assembling the welding sheet in step 2) and the piece to be welded;

[0057] Step 4) Assemble the welded sheet and the welded part in step 3) through such as Figure 7 The advanced atmospheric pressure reflow soldering process makes the solder sheet and the welded piece metallurgically combined to form a Sn96.5Ag3Cu0.5 soft solder layer on the surface ...

Embodiment 3

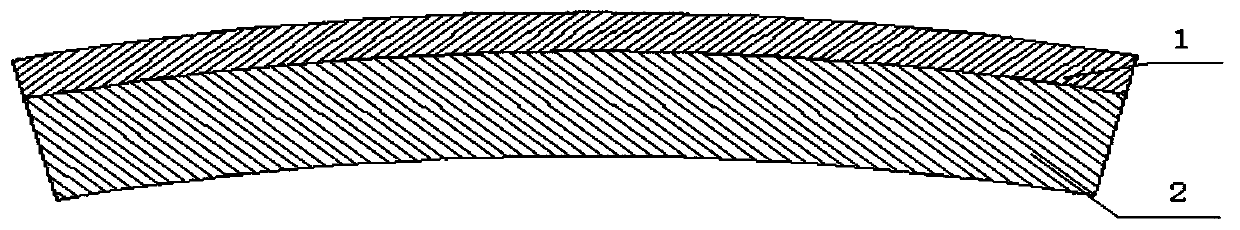

[0060] Figure 1c The surface material of the part to be welded is aluminum, the composition of the soft solder layer is Sn83.6In8.8Zn7.6 in tin-based solder, and the thickness of the soft solder layer is 0.4mm. The preparation method comprises the following steps:

[0061] Step 1) Prepare the configured Sn83.6In8.8Zn7.6 soft solder into a strip of required thickness by calendering;

[0062] Step 2) cutting the strip in step 1) into a solder sheet having a size equivalent to the surface of the welded piece, and coating the solder sheet with a rosin-type flux suitable for welding aluminum parts;

[0063] Step 3) Assembling the welding sheet in step 2) and the piece to be welded;

[0064] Step 4) Put the assembled solder piece and welded part in step 3) through the induction welding process: the temperature is controlled at 230 ° C ~ 250 ° C, after the solder piece is melted, remove the welded part, and then air cool the welded part Until the soft solder layer is solidified, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com