High-barrier transparent oxide composite film and preparation method thereof

A technology of high-barrier composite film and transparent oxide, which is applied in the direction of chemical instruments and methods, flexible coverings, and other household appliances. It can solve the problems of difficult production in factories, complex structural composition, and general barrier properties of products, and achieve good performance. Effects of gas and oil barrier properties, enhanced barrier properties, excellent water vapor and gas barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

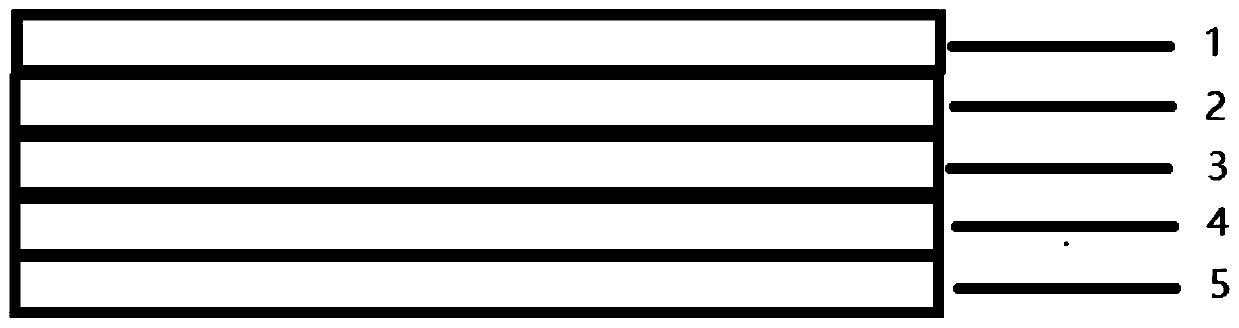

[0040] The present invention also provides a method for preparing the transparent oxide high-barrier composite film, comprising: coating the first adhesive on one side of the polyamide film, and then compounding it with the transparent oxide-coated polyester film to obtain A polyamide film compounded with a polyester film coated with a transparent oxide; the first adhesive forms a first adhesive layer; the polyamide film compounded with a polyester film coated with a transparent oxide and a transparent oxide film The opposite side of the polyester film is coated with a second adhesive, and then compounded with the polypropylene film to obtain a transparent oxide high-barrier composite film; the second adhesive forms a second adhesive layer.

[0041] Wherein, the present invention has no special limitation on the sources of all raw materials, which can be commercially available; the polyamide film, the first adhesive layer, the transparent oxide coated polyester film, the second...

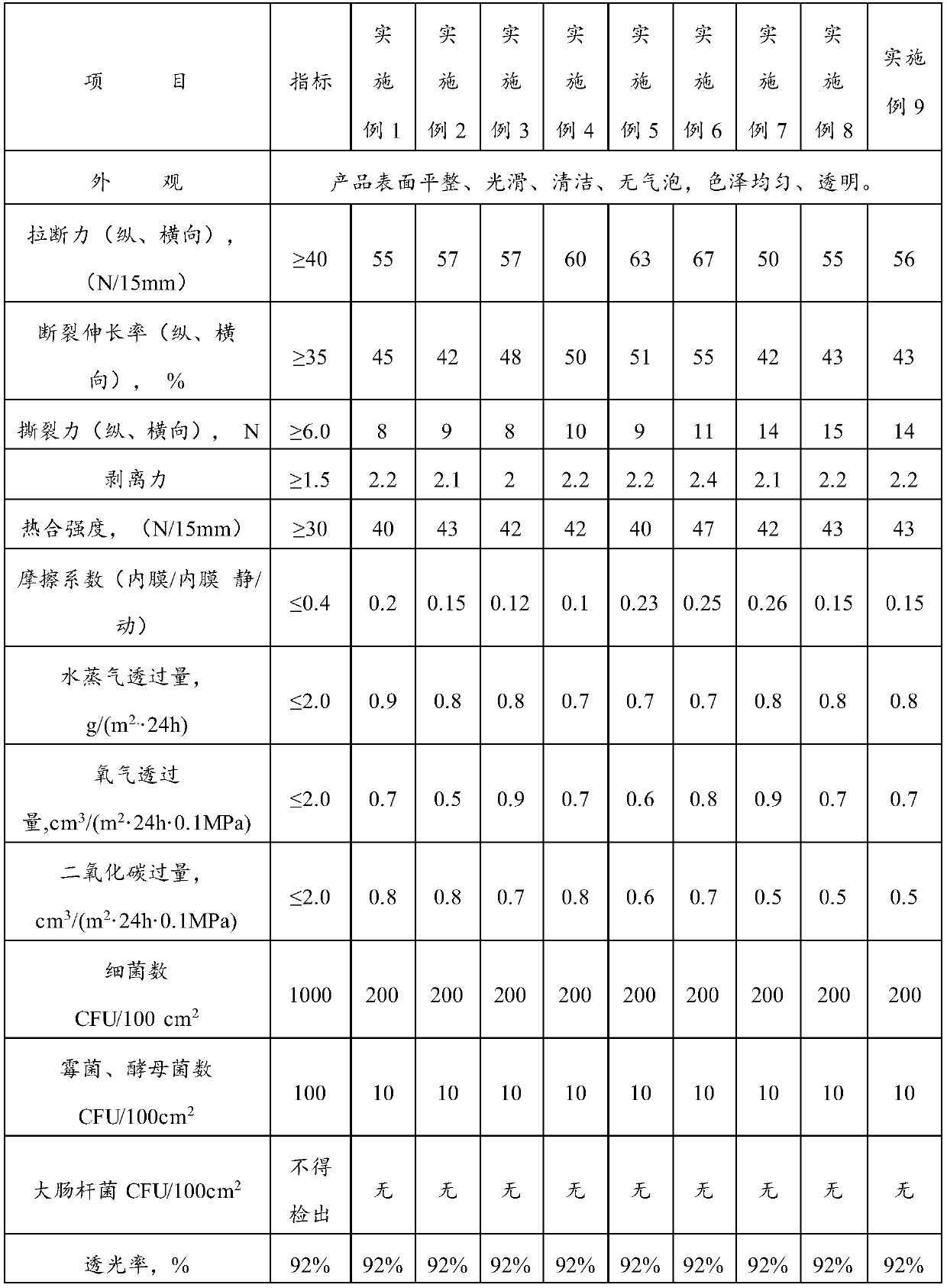

Embodiment 1

[0050] The Donghong (double-sided corona) BOPA film (20 μm) is placed in the position of the dry composite machine, and its surface is coated with a composite adhesive (the glue amount of the adhesive is 2.5g / m 2 ), dry at 45°C for 1 hour, and perform the first dry lamination with the Mitsubishi Chemical LX film (10 μm) placed in the second place of the dry lamination machine to form a lamination of BOPA film / oxide-coated PET brush film. film; then a composite film made of BOPA film / oxide-plated PET film is placed in the position of the dry compound machine, and its surface is coated with a composite adhesive (the glue amount of the adhesive is 2.5g / m 2 ), dry at 45°C for 1 hour, and dry-laminate with Meifeng 121°C cooking CPP film (80μm) placed in the second dry lamination machine to form oxide-coated PET film / BOPA film / RCPP Transparent oxide high barrier composite film. The adhesive used between the film layers is composite glue-polyurethane:curing agent-polyurethane:solven...

Embodiment 2

[0052] The Donghong (double-sided corona) BOPA film (10 μm) is placed in the position of the dry composite machine, and its surface is coated with a composite adhesive (the glue amount of the adhesive is 2.5g / m 2), dry at 35°C for 4 hours in the drying tunnel, and perform the first dry lamination with the Toppan GL film (50 μm) placed in the second place of the dry lamination machine to form a lamination film composed of BOPA film / oxide-coated PET brush film ; Then a composite film made of BOPA film / plated oxide PET film is placed in the position of the dry composite machine, and its surface is coated with a composite adhesive (the amount of glue applied to the adhesive is 2.5g / m 2 ), dried at 35°C for 4 hours in the drying tunnel, and then dry-laminated with Meifeng 121°C cooking CPP film (35μm) placed in the second dry lamination machine to form oxide-coated PET film / BOPA film / RCPP Transparent oxide high barrier composite film. . The adhesive used between the film layers i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com