Carbon nano-tube-porous carbon composite material preparation method

A technology of composite materials and carbon nanotubes, which is applied in the direction of carbon nanotubes, carbon preparation/purification, nano-carbon, etc., can solve the problems of high cost of organic ligands, long synthesis cycle, unfavorable industrial scale production, etc., and achieve low cost , high conductivity, conducive to the effect of large-scale mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of carbon nanotube-porous carbon composite material, comprising the steps of:

[0045] (1) Disperse 10g of lamellar porous magnesium oxide in 100mL of water to obtain a suspension, then drop nickel nitrate solution (dissolve 0.63g of nickel nitrate in 8mL of water) into the suspension, and mix it uniformly by ultrasonication for 30min. Suction filtration, drying and pulverizing the obtained filter residue, and then calcining at 550° C. for 30 minutes to obtain a carbon tube template;

[0046] (2) Add 10g of carbon tube templating agent and 10g of asphalt into solvent ethanol, stir and mix evenly, dry, put the obtained powder in a porcelain boat, and calcinate in a high-temperature tube furnace at 800°C under the protection of nitrogen 30min, then cool down and take it out to obtain black powder, rinse the black powder with dilute hydrochloric acid and rinse it to neutrality with deionized water, and finally filter it with suction and dry it to obtai...

Embodiment 2

[0055] A preparation method of carbon nanotube-porous carbon composite material, comprising the steps of:

[0056] (1) The preparation of carbon tube template is the same as in Example 1;

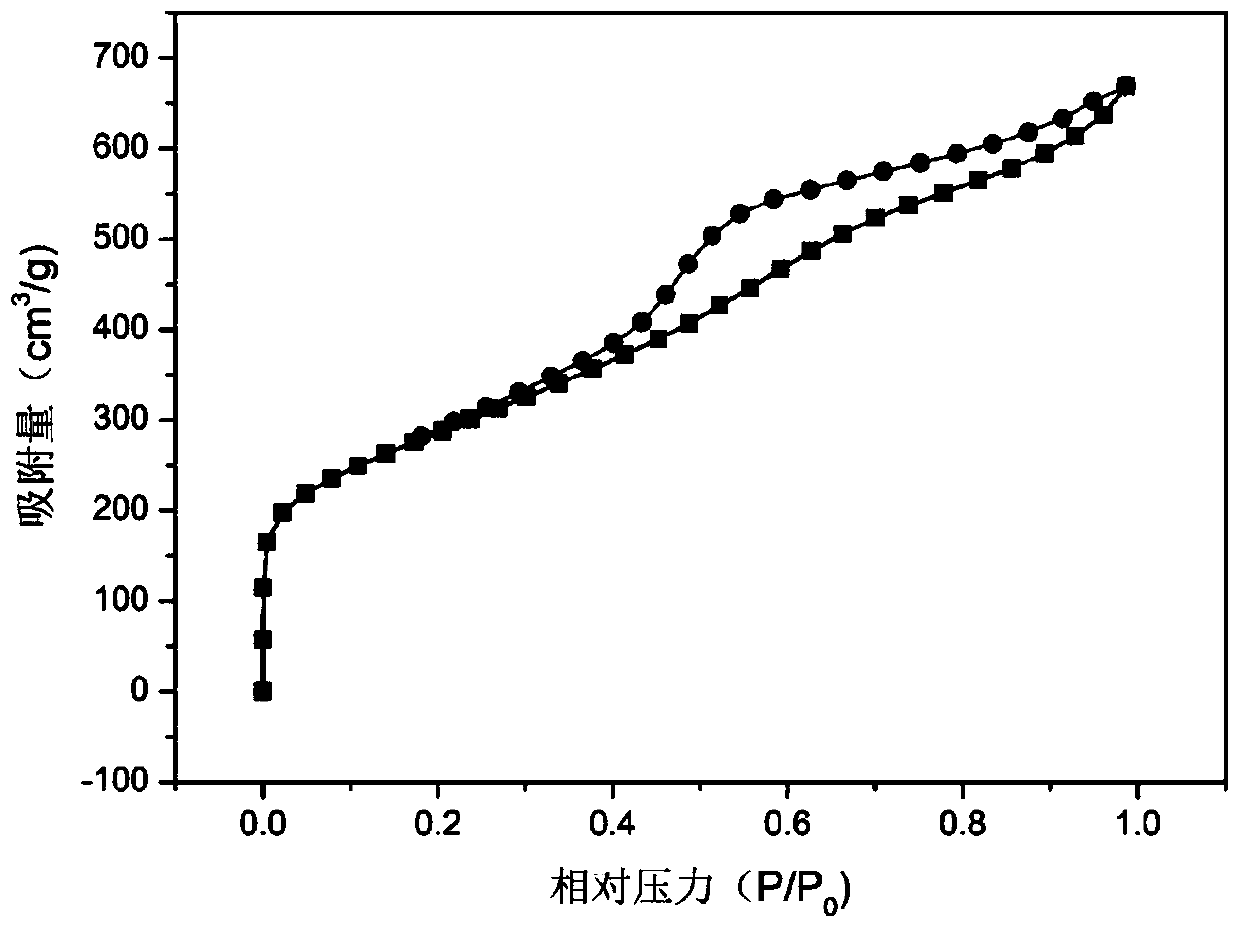

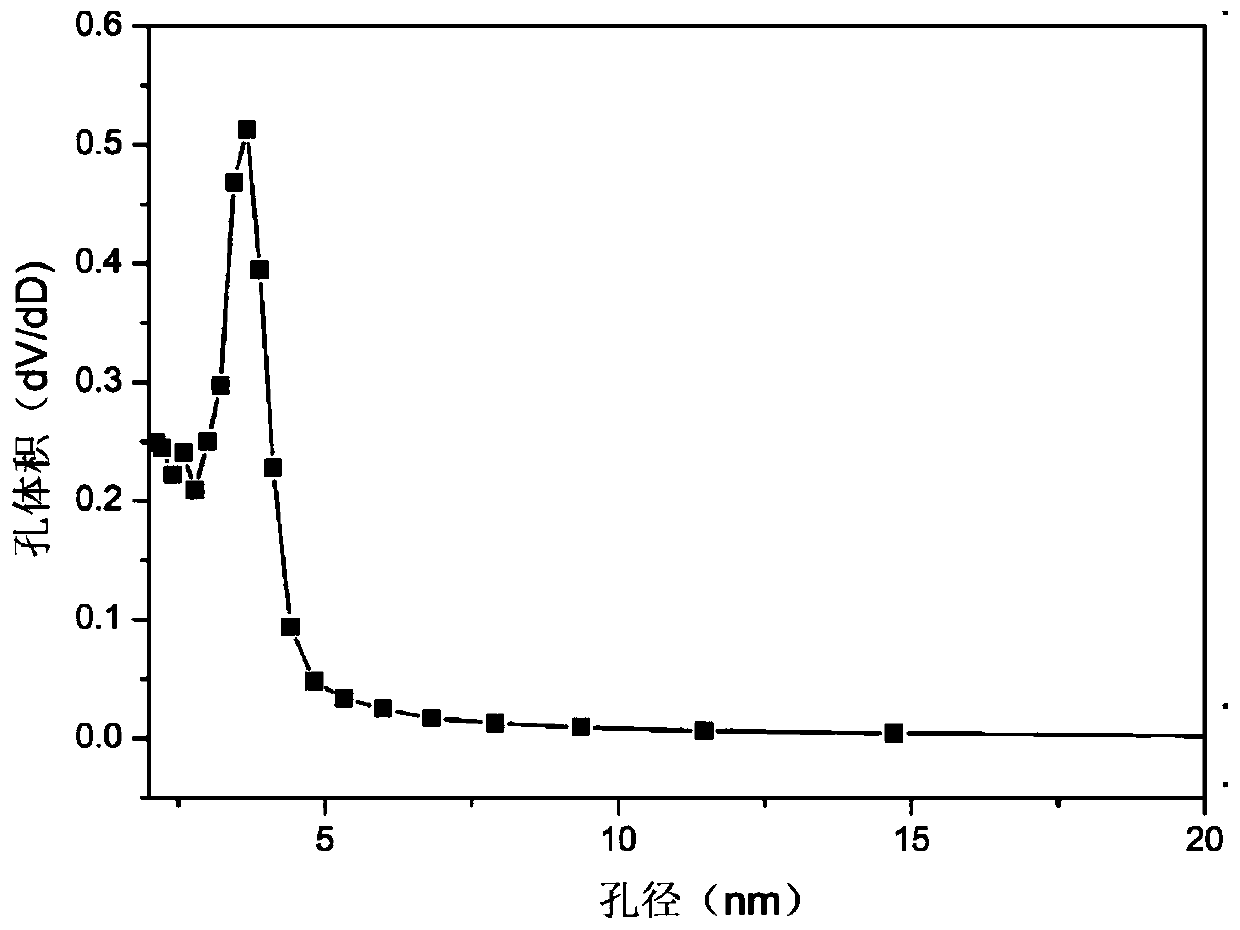

[0057] (2) Add 10g of carbon tube templating agent and 10g of asphalt into solvent ethanol, stir and mix evenly, dry, put the obtained powder in a porcelain boat, and calcinate at 900°C in a high-temperature tube furnace under nitrogen protection 20min, then cool down and take it out to get a black powder, pickle the black powder with dilute hydrochloric acid, rinse it with deionized water until neutral, and finally filter it with suction and dry it to get the carbon nanotube-porous carbon composite material, and measure the specific surface area 984.6m 2 / g.

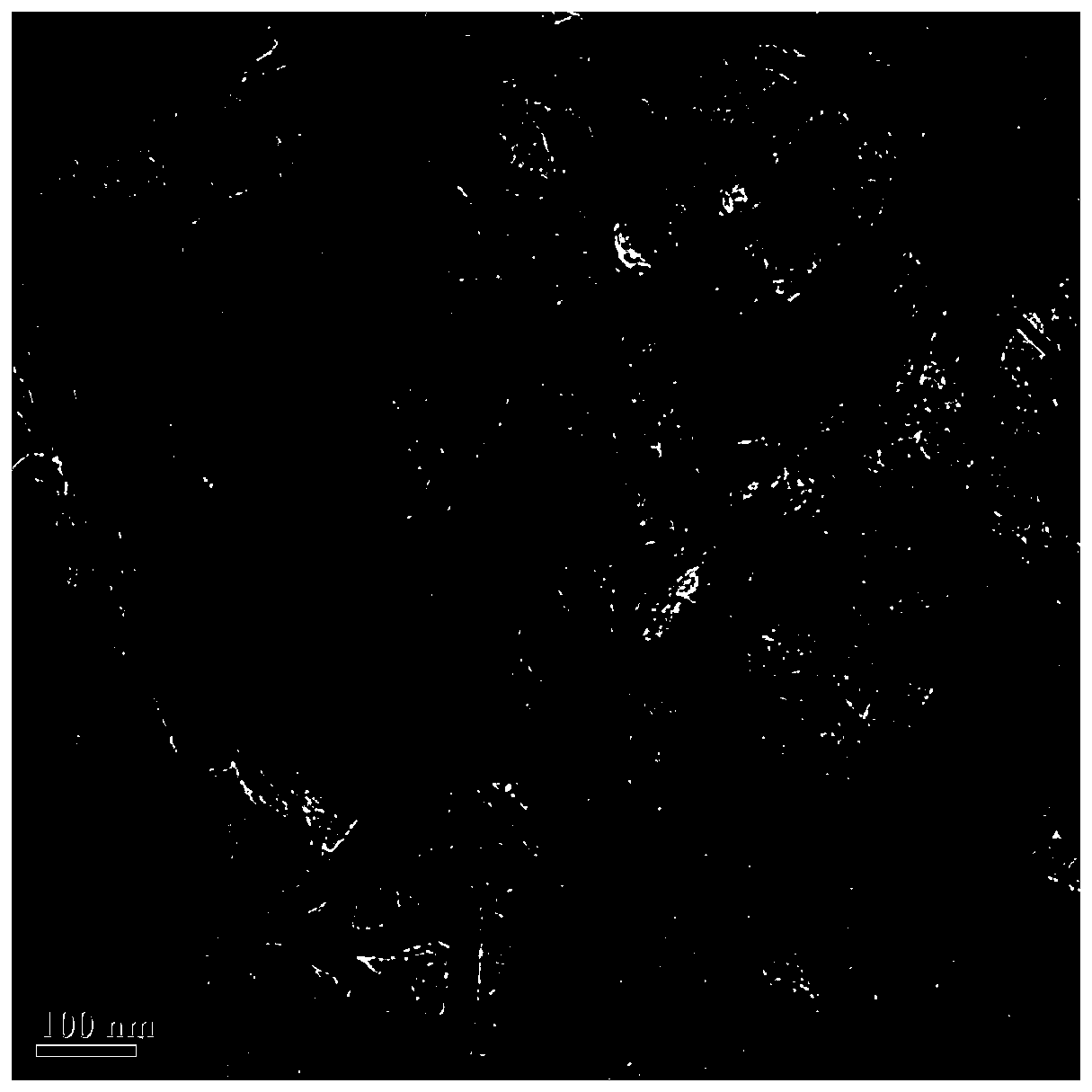

[0058] The transmission electron microscope figure of the carbon nanotube-porous carbon composite material that embodiment 2 makes is shown in Figure 9 ,Depend on Figure 9 It can be seen that a large number of carbon nanotubes ...

Embodiment 3

[0062] A preparation method of carbon nanotube-porous carbon composite material, comprising the steps of:

[0063] (1) The preparation of carbon tube template is the same as in Example 1;

[0064] (2) Add 10g of carbon tube templating agent and 15g of oil slurry into the solvent tar, stir and mix evenly, dry, put the obtained powder in a porcelain boat, and put it in a high-temperature tube furnace under nitrogen protection at 800°C Calcined for 40min, then cooled and taken out to obtain black powder, the black powder was pickled with dilute hydrochloric acid, rinsed with deionized water to neutrality, and finally filtered and dried to obtain the carbon nanotube-porous carbon composite material. Surface area is 993.2m 2 / g.

[0065] The electron micrograph of the carbon nanotube-porous carbon composite material that embodiment 3 makes is shown in Figure 13 , where A is the scanning electron microscope image, and B is the transmission electron microscope image. It can be se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com